Preparation method of lubricating oil tackifier with high shear resistance

A technology for lubricating oil and tackifier, which is applied in the field of preparation of lubricating oil tackifier, can solve the problems of poor mass transfer and heat transfer effect, narrow OCP polymer VII, difficult control of degradation degree, etc., and achieves full automation of production process , The effect of improving shear resistance and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

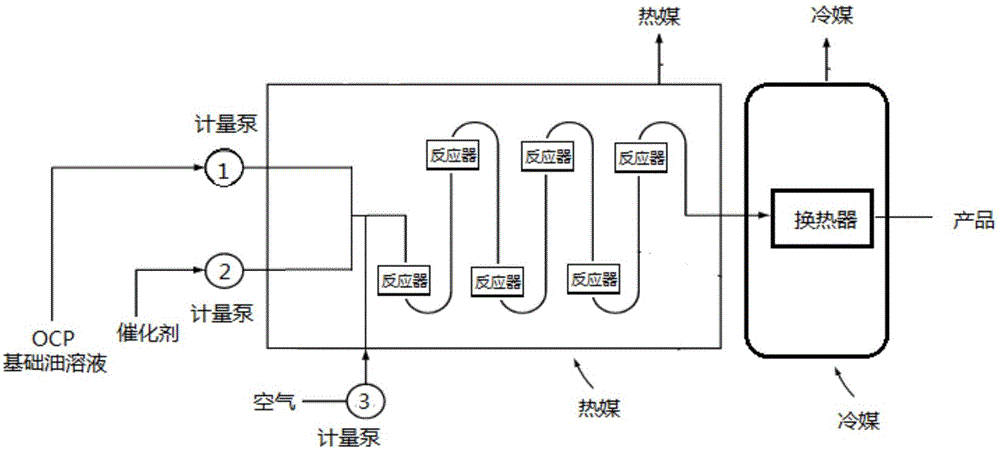

Method used

Image

Examples

Embodiment 1

[0025] Add 127g of base oil (MVI 150) into a 250ml glass container equipped with a stirrer, thermometer, heating mantle and air pipe, start stirring, heat to 140°C, then add 22g of ethylene propylene rubber cut into small pieces (Jilin Petrochemical J-0050, ML (100°C, 1+4) 50±5), completely dissolved as component 1 for later use. After the temperature of the reactor (Corning's heart-shaped structural glass material microchannel reactor) reaches 150°C, the base oil solution of ethylene-propylene rubber (ie, component 1) and the catalyst peroxidation are started to be fed quantitatively and continuously. Methyl ethyl ketone 0.015g and air are passed into the reactor, the base oil solution flow rate of ethylene propylene rubber is 45ml / min, the catalyst flow rate is 0.003g / min, the air flow rate is 70ml / min, the residence time in the reactor is 8min, and then enters the heat exchange The device cools down and discharges the material.

[0026] The molecular weight distribution of...

Embodiment 2

[0028] Add 127g of base oil (MVI 150) into a 250ml glass container equipped with a stirrer, thermometer, heating mantle and air pipe, start stirring, heat to 140°C, then add 22g of ethylene propylene rubber cut into small pieces (Jihua J-0030, ML (100°C, 1+4) 30±5), completely dissolved as component 1 for later use. After the temperature of the reactor (Corning's heart-shaped structural glass material microchannel reactor) reaches 160°C, the base oil solution of ethylene-propylene rubber (ie component 1), catalyst 2, and 5-Dimethyl-2,5-di(t-butylperoxy)hexane 0.08g and air are passed into the reactor, the base oil solution flow rate of ethylene propylene rubber is 40ml / min, and the catalyst flow rate is 0.016g / min , the air flow rate is 50ml / min, the residence time in the reactor is 5min, then enters the heat exchanger to cool down, and discharges.

[0029] The obtained OCP polymer VII has a molecular weight distribution of 1.4-1.6 and a thickening capacity of 8.2mm 2 / s, shea...

Embodiment 3

[0031] Add 127g of base oil (MVI 150) into a 250ml glass container equipped with a stirrer, thermometer, heating mantle and air pipe, start stirring, heat to 140°C, then add 22g of ethylene propylene rubber cut into small pieces (Jilin Petrochemical J-0010:J-0050=8:2 (mass ratio)), completely dissolved as component 1 for later use. After the temperature of the reactor (Corning's heart-shaped structural glass material microchannel reactor) reaches 140°C, the base oil solution of ethylene-propylene rubber (ie component 1), catalyst two ( 0.15g of tert-butylperoxycumene)benzene and air pass into the reactor, the base oil solution flow rate of ethylene propylene rubber is 40ml / min, the catalyst flow rate is 0.025g / min, and the air flow rate is 80mL / min. The residence time is 6min, then enters the heat exchanger to cool down, and discharges.

[0032] The obtained OCP polymer VII has a molecular weight distribution of 1.4-1.6 and a thickening capacity of 8.3mm 2 / s, shear stabilit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com