Patents

Literature

65results about How to "No stability issues" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

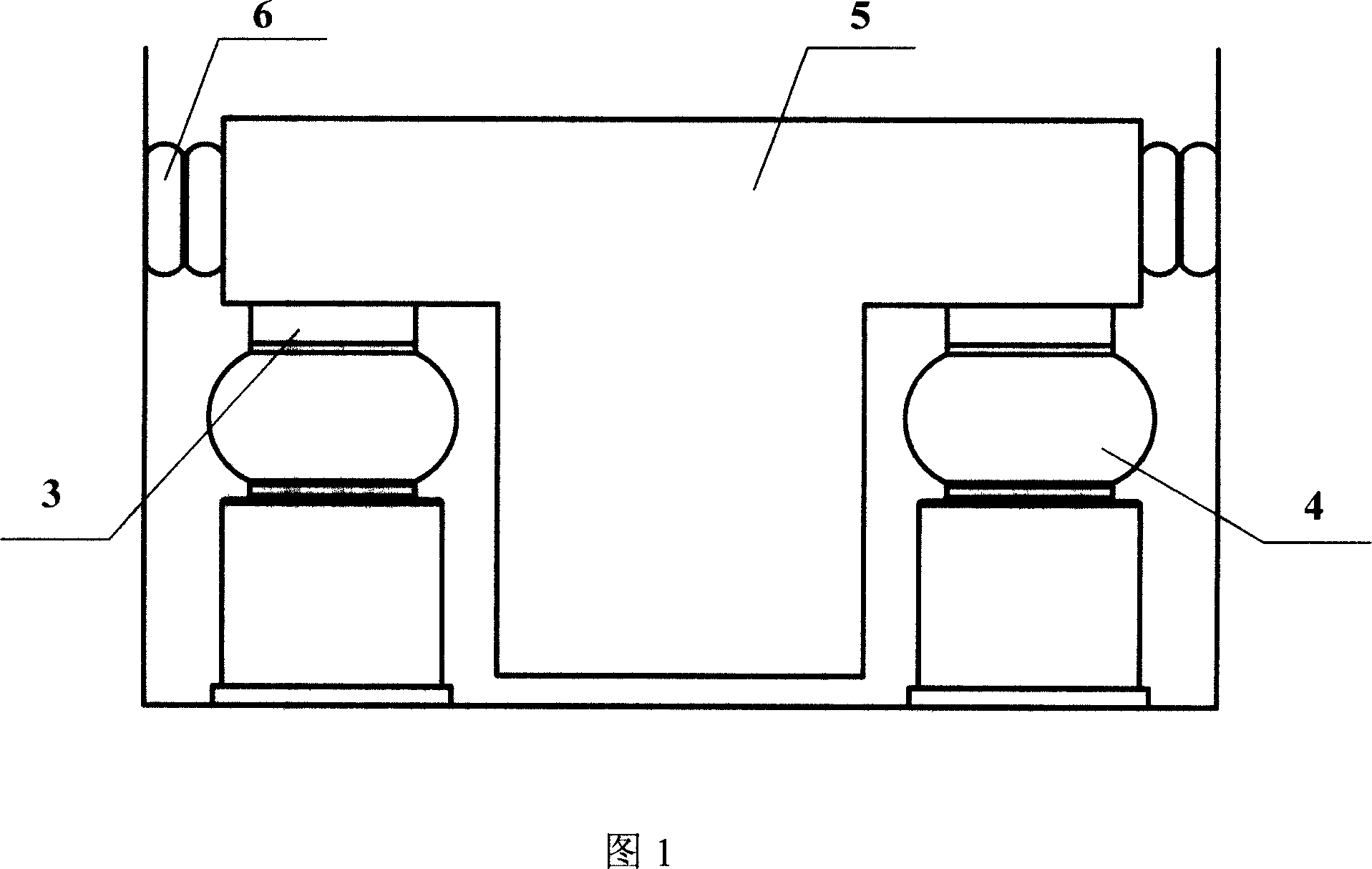

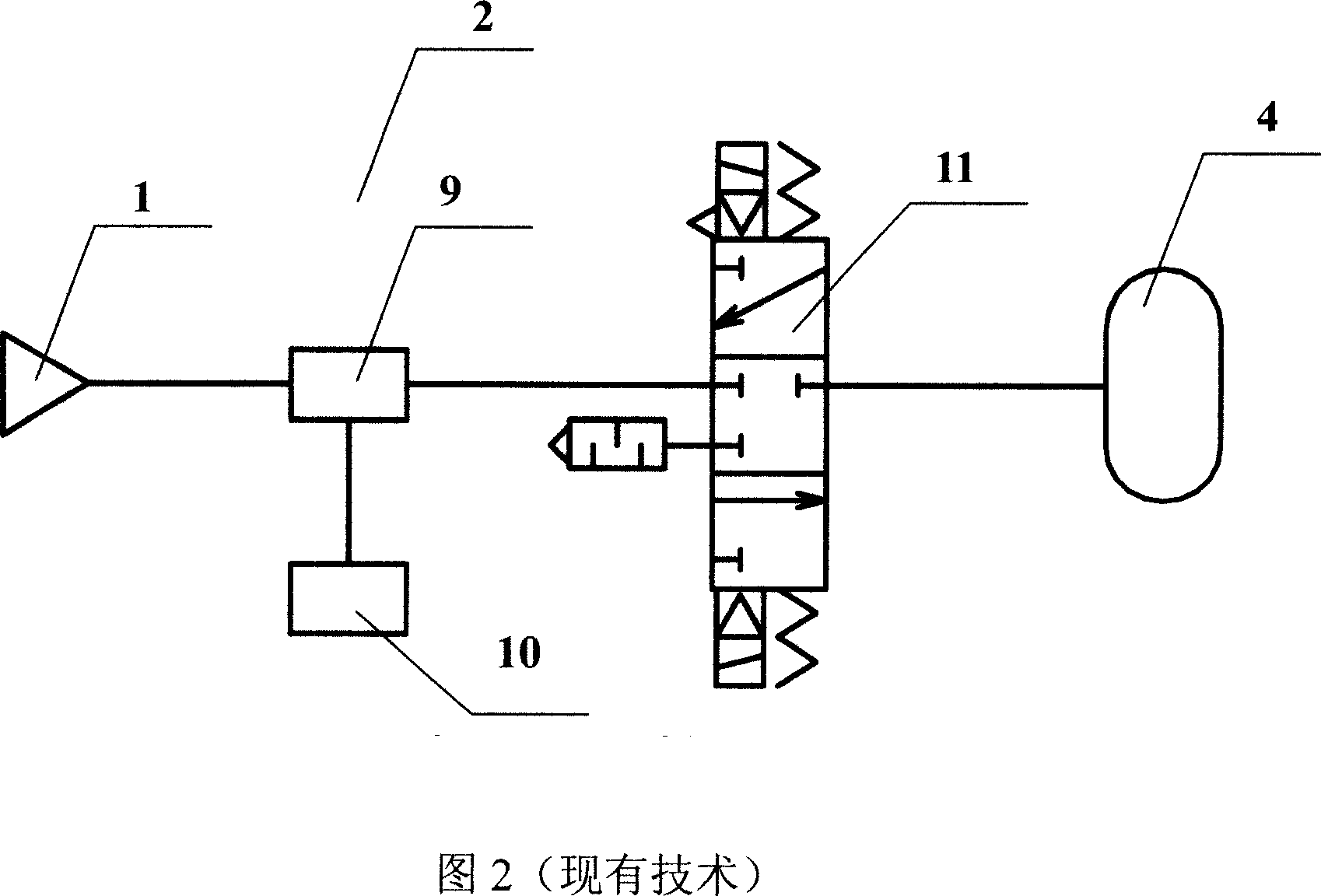

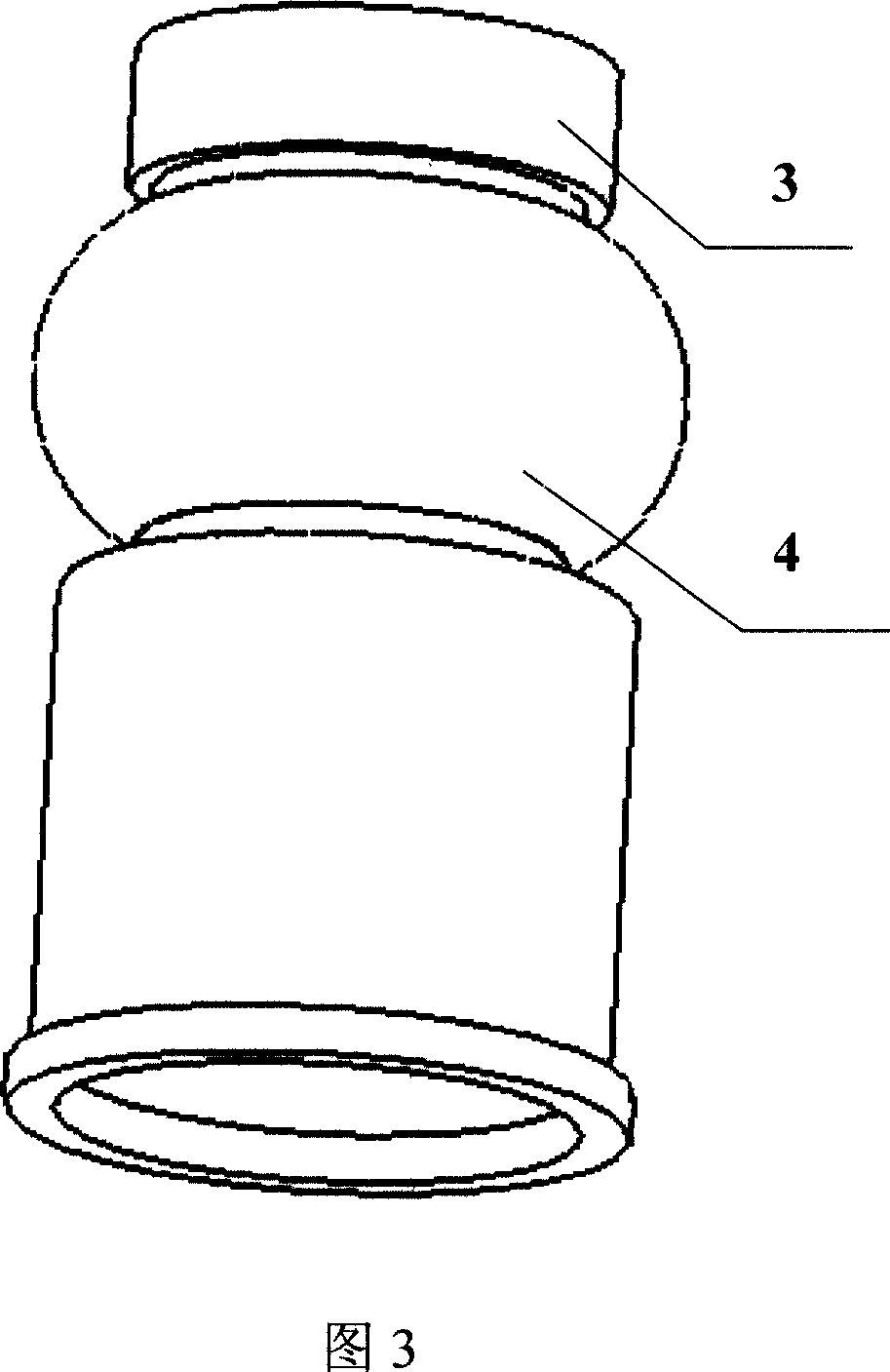

Air spring vibro-damping mount with magnetic suspension unit

InactiveCN101067432ALow costReduce lateral stiffnessNon-rotating vibration suppressionAir springAir suspension

The air spring vibrating isolation base with the magnetic suspension unit includes the: the basal body, a group of air spring, the air feed system, the high controlling system, many magnetic suspension units, the low stiffness righting device. The input of the air feed system and the high controlling system are connected with each other. The output of the high controlling system is connected with every air spring; the magnetic suspension unit is connected to the air feed system. The magnetic suspension and the air spring are connected under the basal body in series to support it; the side of the basal body is installed with the low rigidity righting device. The invention can be proper for the super high air spring isolation base in the condition of not changing the bearing ability of the vibration separation system.

Owner:HARBIN INST OF TECH

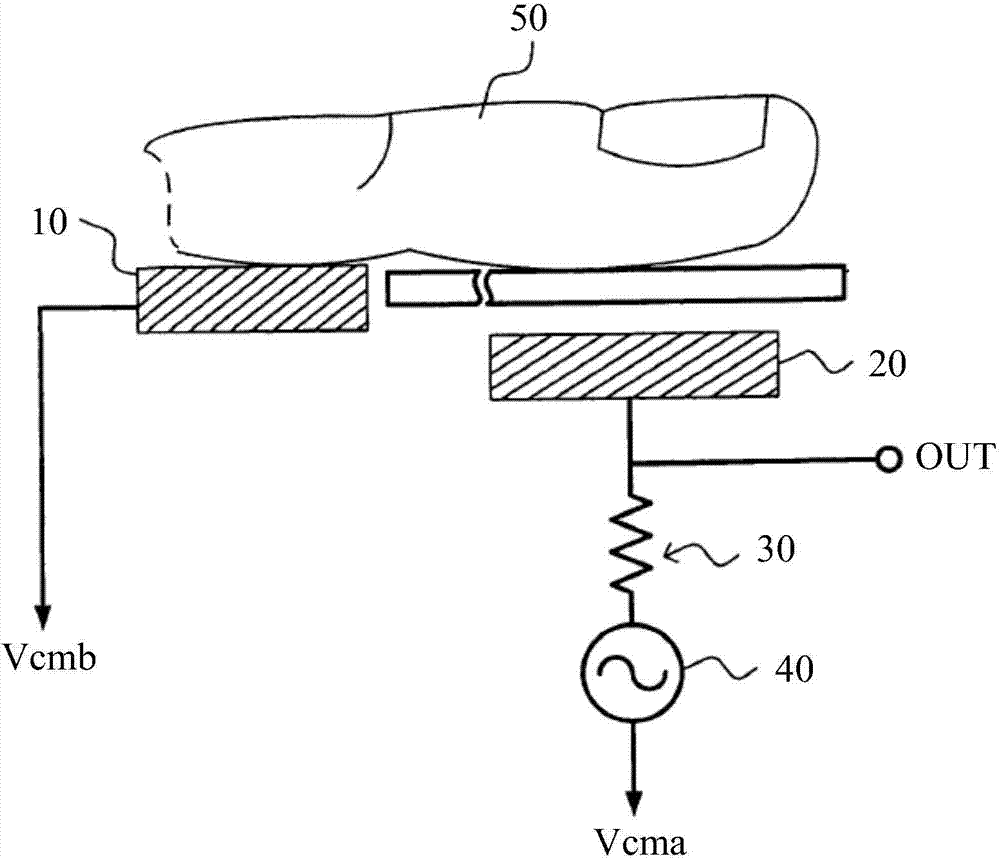

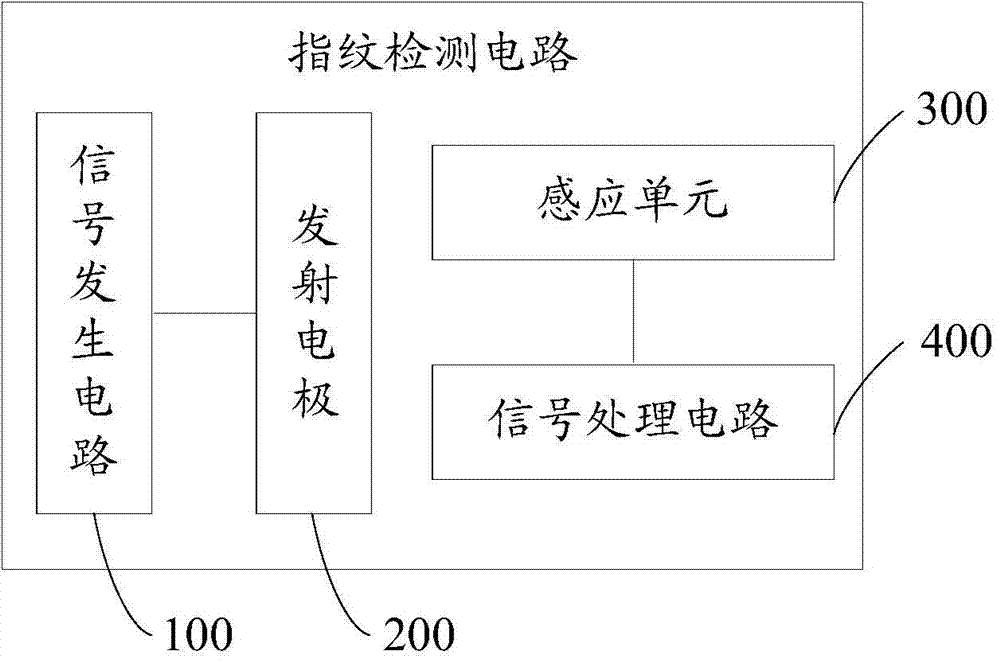

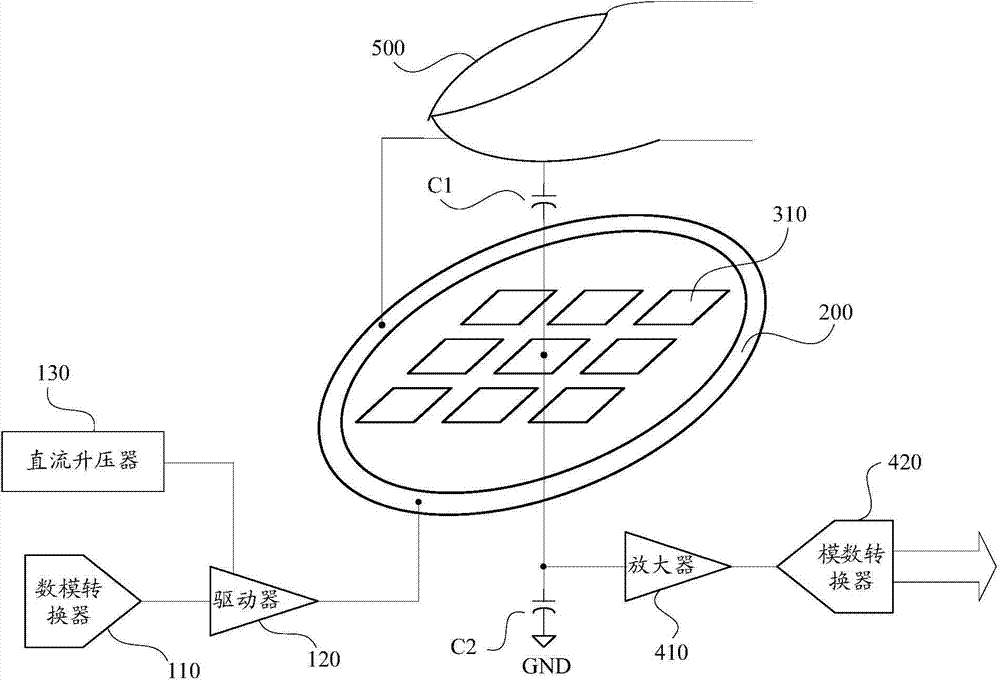

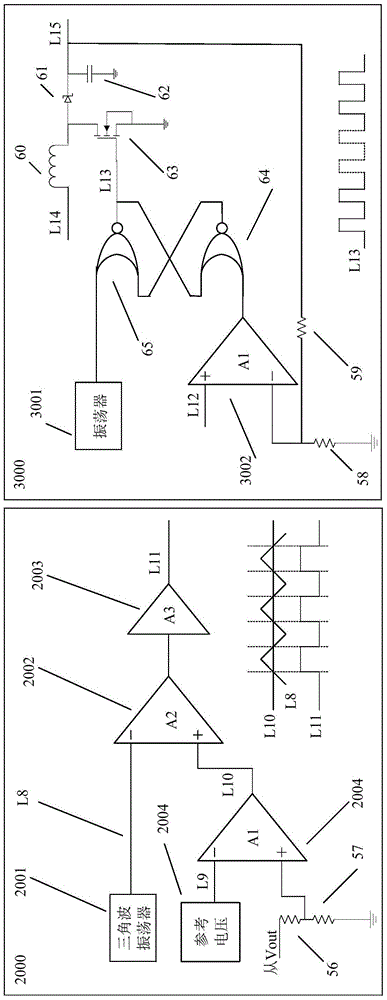

Fingerprint detection circuit and fingerprint detection device

The invention discloses a fingerprint detection circuit and a fingerprint detection device. The fingerprint detection circuit comprises a signal generation circuit, an emitting electrode, an induction unit and a signal processing circuit, wherein the signal generation circuit is used for generating an alternating-current signal, the emitting electrode is used for transmitting the alternating-current signal to fingers, the induction unit is used for collecting fingerprint information of the fingers, the signal processing circuit is used for processing the fingerprint information, and the signal generation circuit is electrically connected with the emitting electrode and the induction unit respectively. In this way, the alternating-current signal with a certain amplitude is coupled to the fingers by the emitting electrode so that a voltage division signal can be formed by the alternating-current signal through a first capacitor formed between the fingers and the induction unit and a second capacitor formed between the induction unit and the ground, output data including fingerprint information are generated after the voltage division signal is processed through the signal processing circuit, and finally fingerprint detection can be completed. Because an open-loop structure is adopted in the whole circuit and any feedback circuit is not adopted, the circuit is low in cost, high in reliability and high in fingerprint detection speed.

Owner:SHENZHEN GOODIX TECH CO LTD

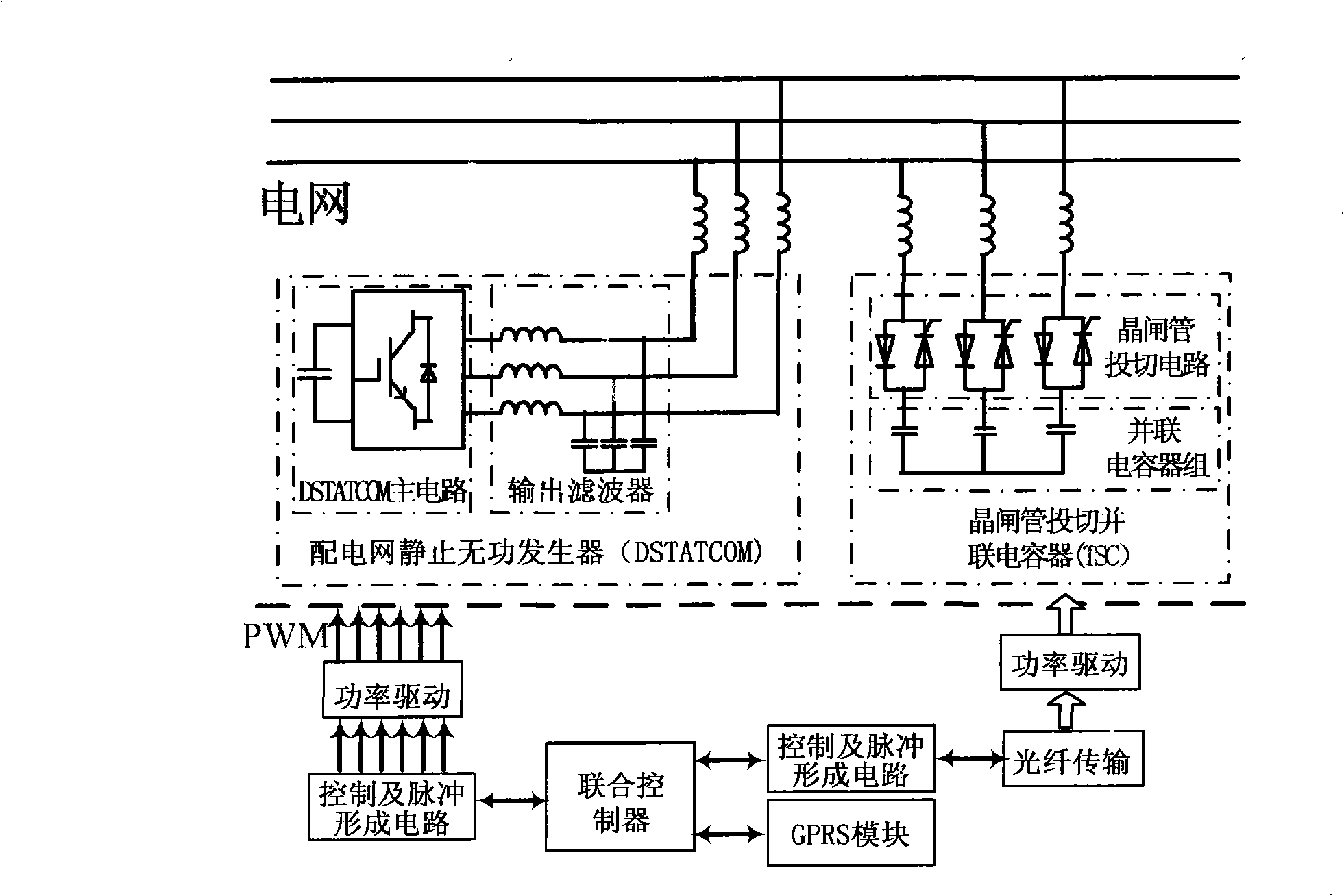

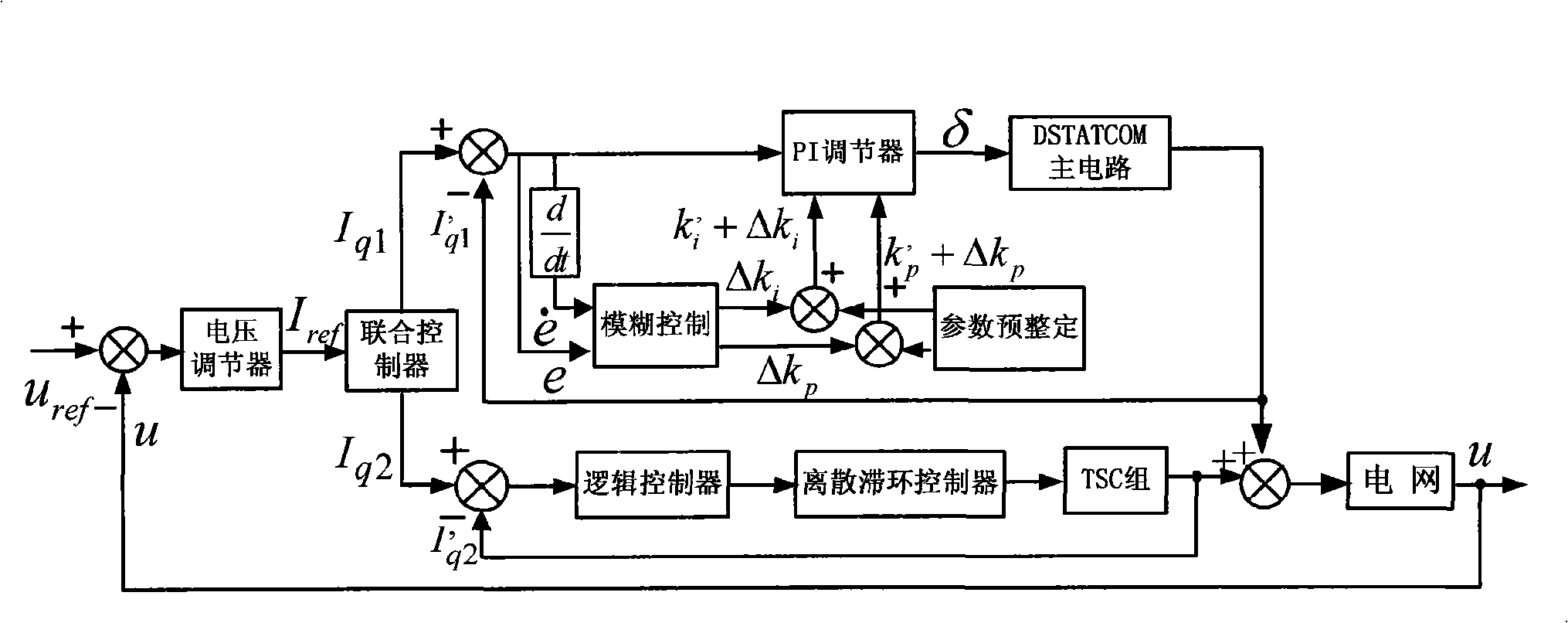

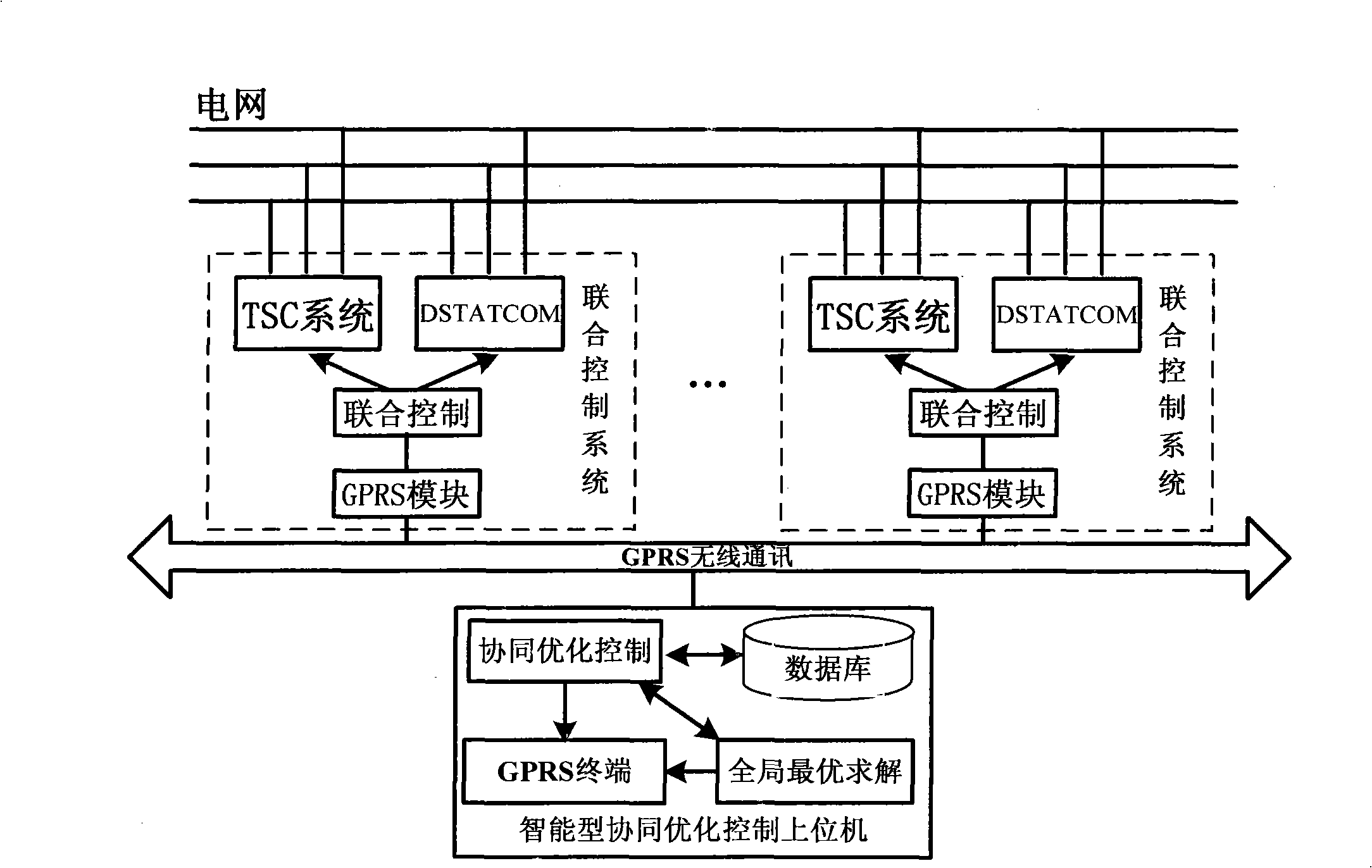

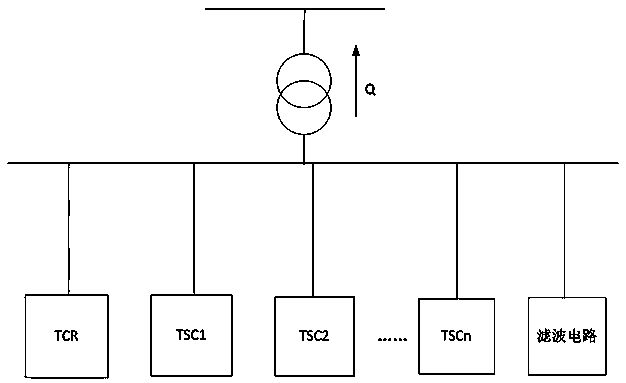

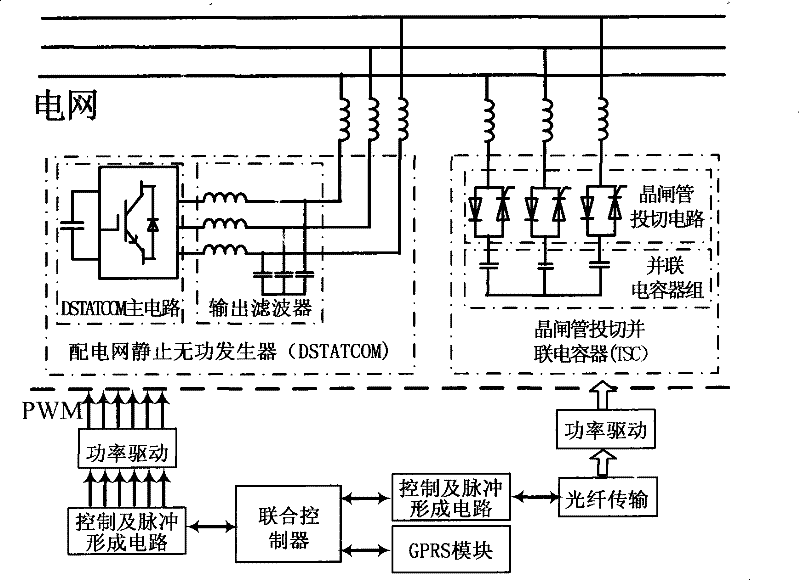

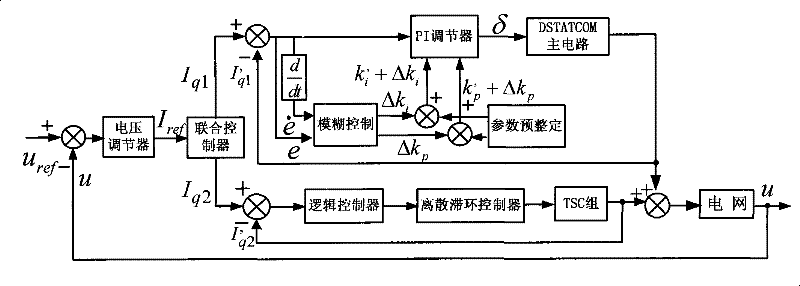

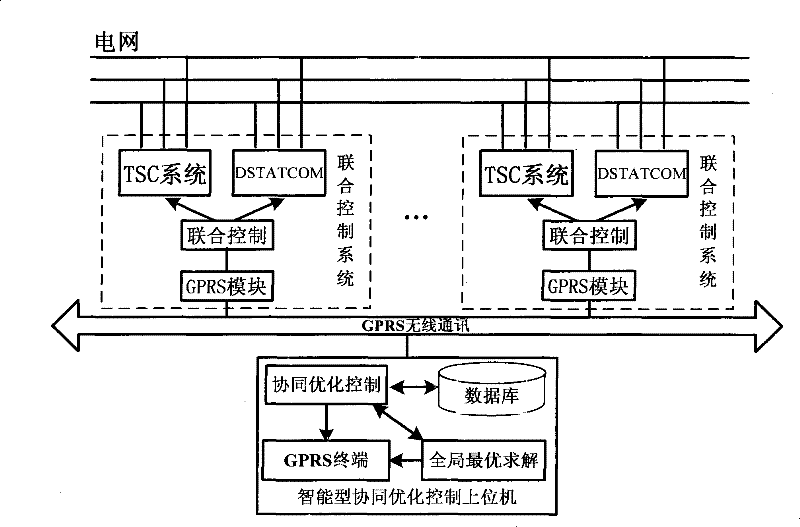

Power distributing reactive optimizing compensation system based on GPRS and control method thereof

InactiveCN101335456ALarge capacityLow costReactive power adjustment/elimination/compensationReactive power compensationPower compensationCapacitance

The invention discloses a reactive power optimum compensation system and a control method thereof of a GPRS-based distribution network. The compensation system of the invention comprises a combination control system and an intelligent upper computer (industrial computer) with collaborative optimization control, wherein, the combination control system coordinately controls TSC and DSTATCOM on the same compensation node by a hybrid dynamic control method, and can also realize the data remote-transmission of the system parameters of the node to the intelligent upper computer with collaborative optimization control by a GPRS wireless communication network; the intelligent upper computer with collaborative optimization control searches the optimum compensation node and the compensation capacity by utilizing a multi-machine collaborative reactive power compensation method and also sends an optimum control command to a combination compensation system which then realizes the local large-capacity and continuous reactive power compensation by classified TSC capacitance switching and continuous DSTATCOM compensation. The reactive power optimum compensation system of the invention effectively solves the defects of poor capacity of resisting disturbance and difficult networking, etc. of the existing reactive power compensation system, and also reduces the operation cost.

Owner:HUNAN UNIV

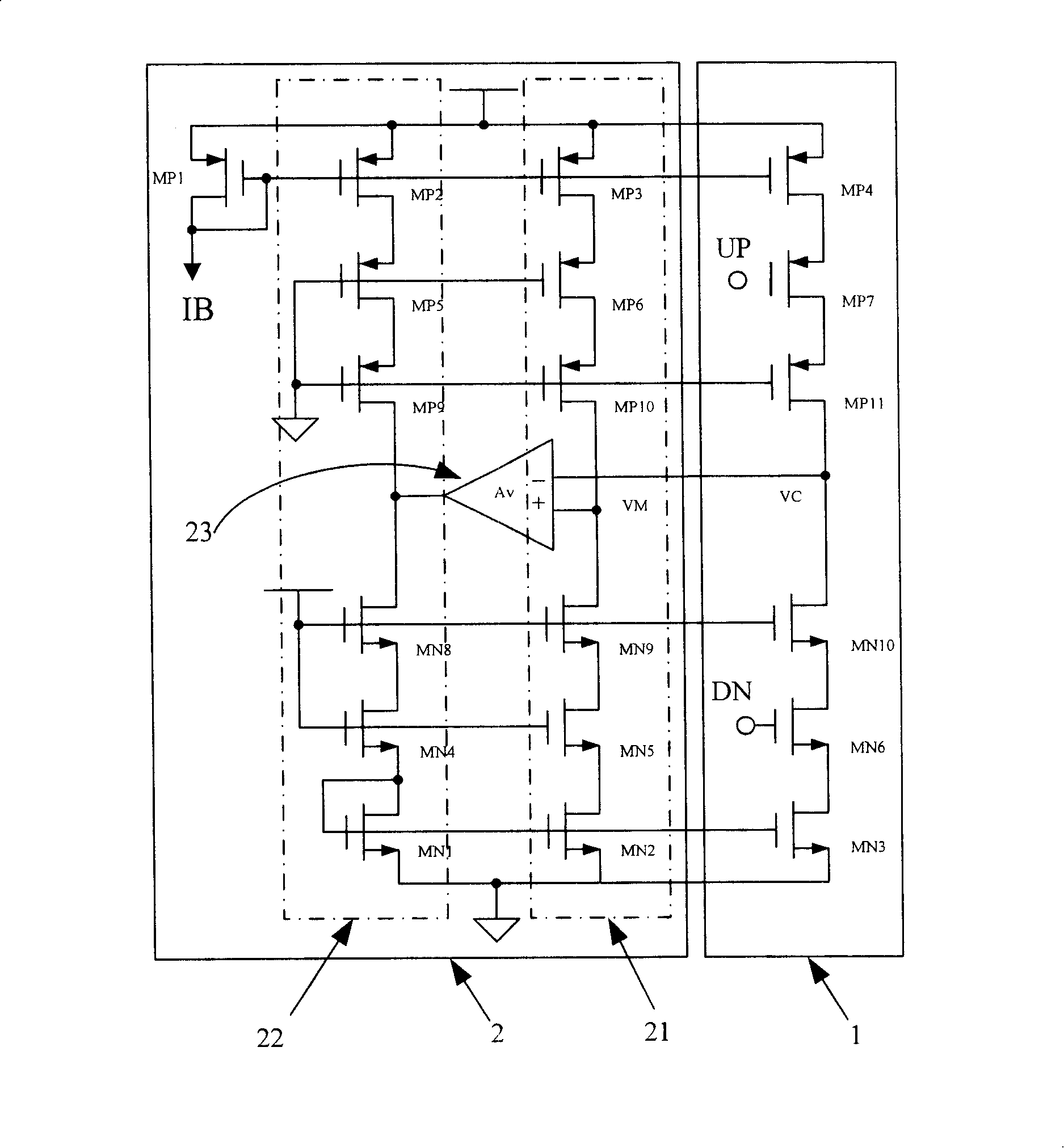

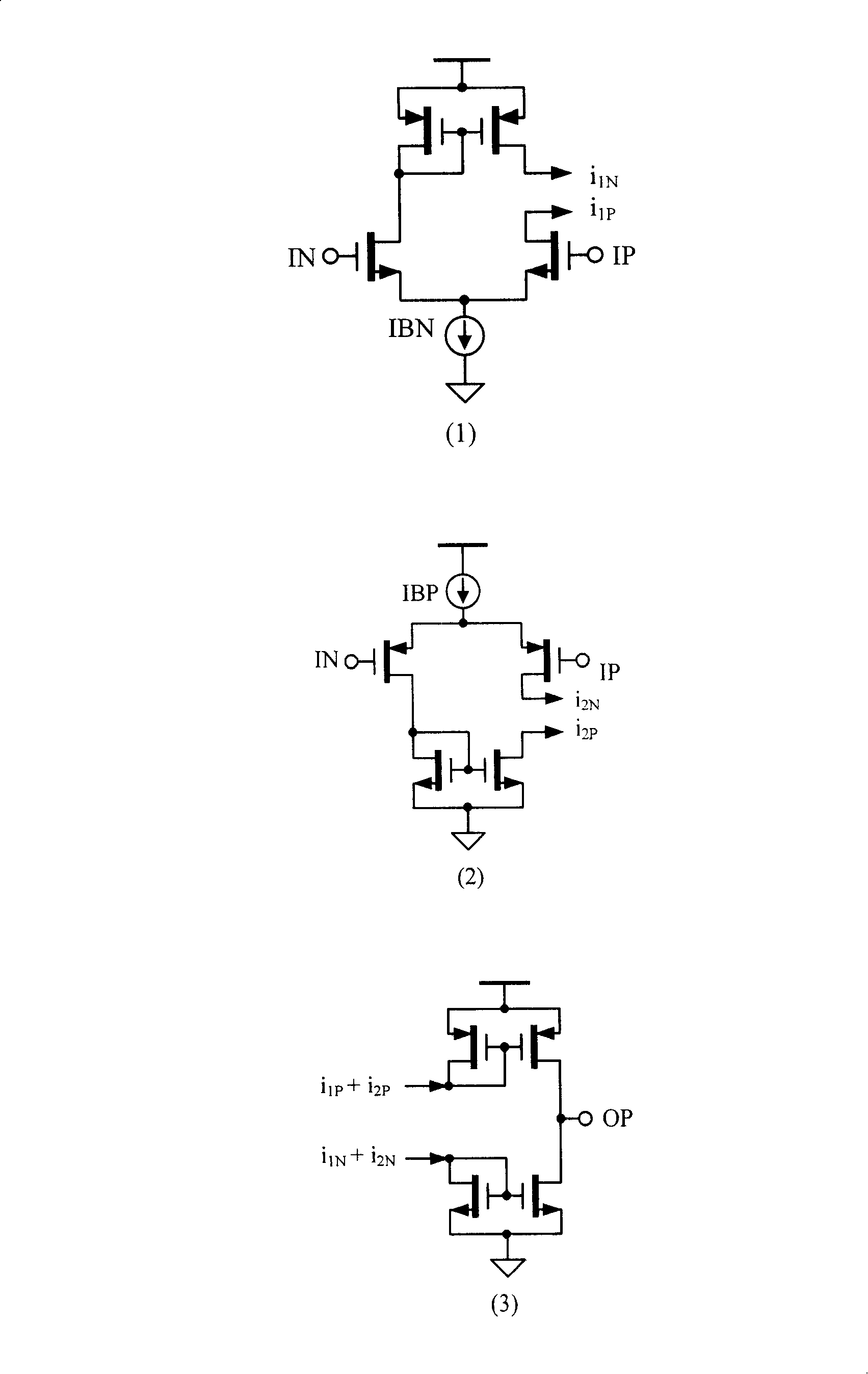

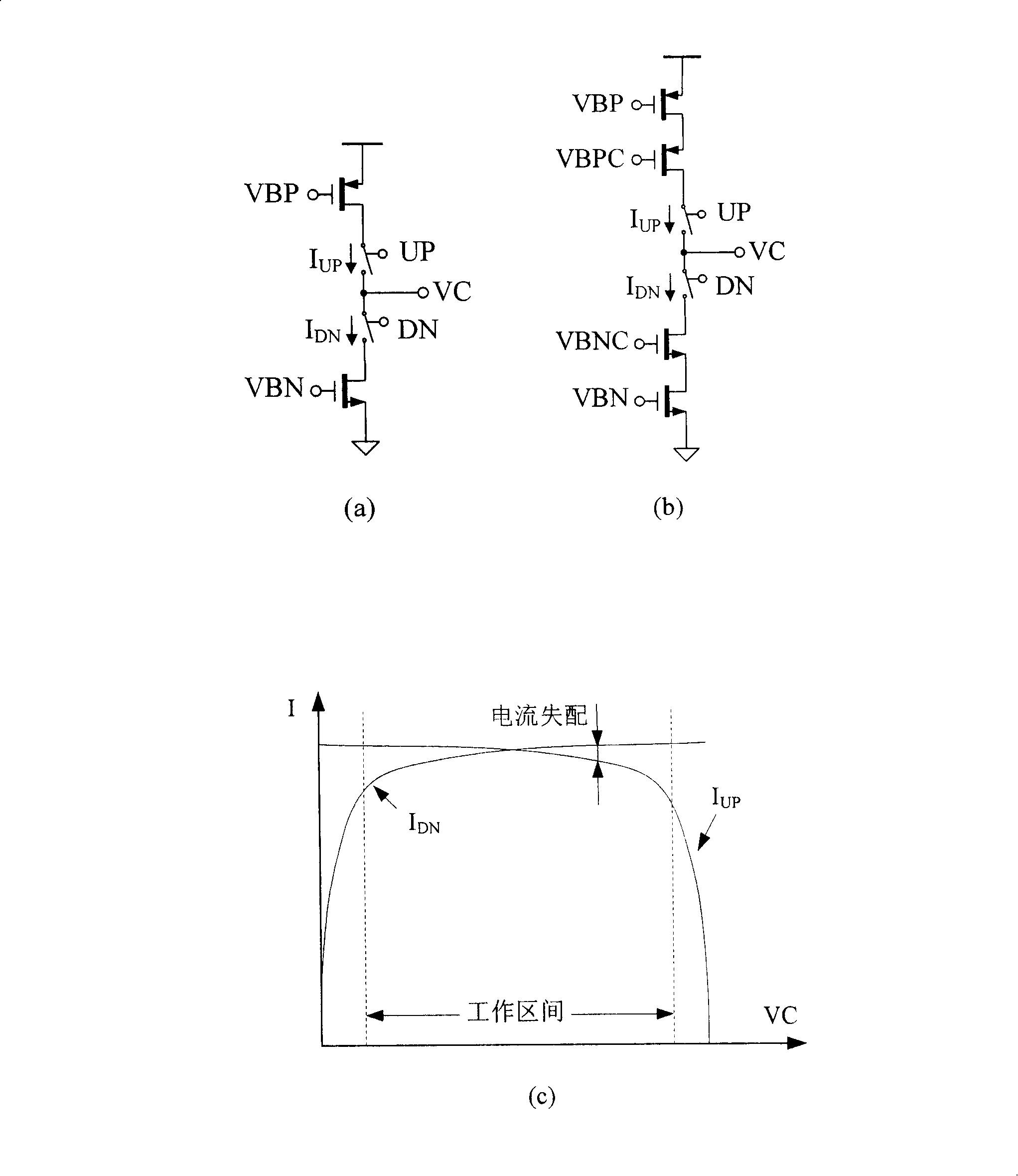

Self-calibration charge pump circuit used for phase-locked loop and its self-calibration feedback loop

InactiveCN101222226AImprove stabilityExpand the output rangePulse automatic controlAudio power amplifierClosed loop feedback

The invention relating to the phase-locked loop charge pump circuit technical field in microelectronics discloses a self-calibration charge pump circuit used in a phase-locked loop. The invention is characterized in that: the self-calibration charge pump circuit comprises a current branch 1 and a self-calibration feedback circuit 2; the self-calibration feedback circuit 2 comprises a reference branch 21, a biasing branch 22 and a feedback amplifier 23; the reference branch 21 and the output node of the current branch 1 are respectively connected with the positive input end and the negative input end of the feedback amplifier 23; the output end of the feedback amplifier 23 is connected with the biasing branch 22 to from a closed-loop feedback loop. The invention also discloses a self-calibration feedback circuit 2 used in a charge pump circuit. The invention solves the problems of unmatched output current and unstable circuit status of a charge pump circuit when output voltage varies in a large range.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

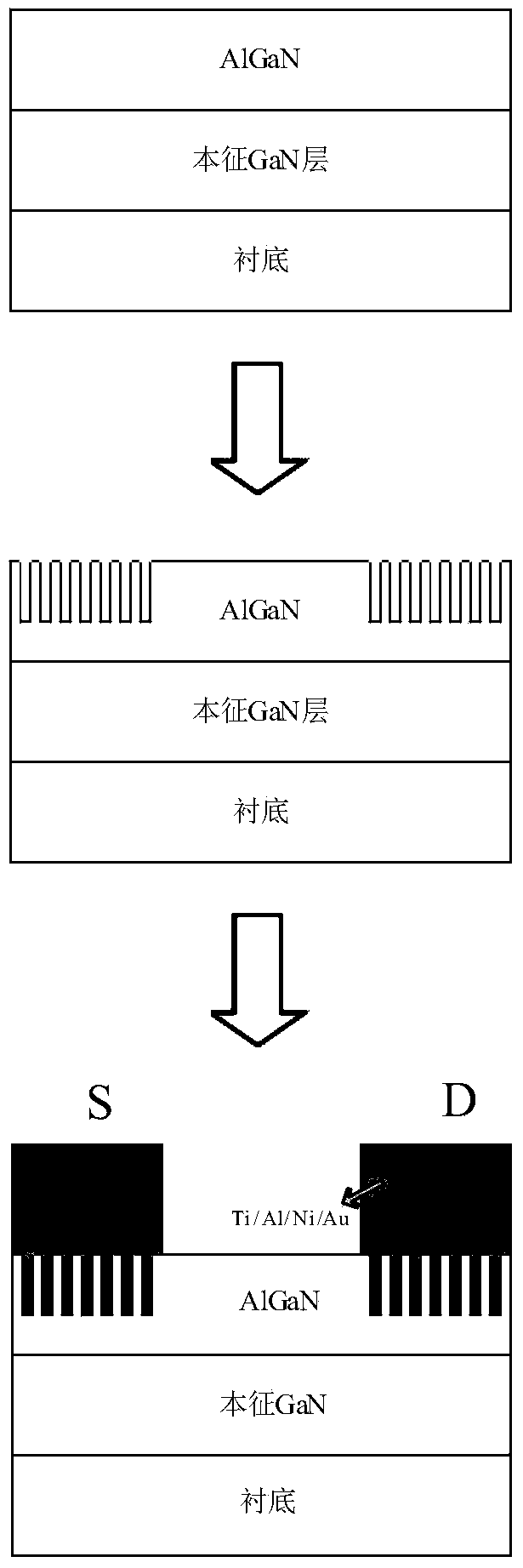

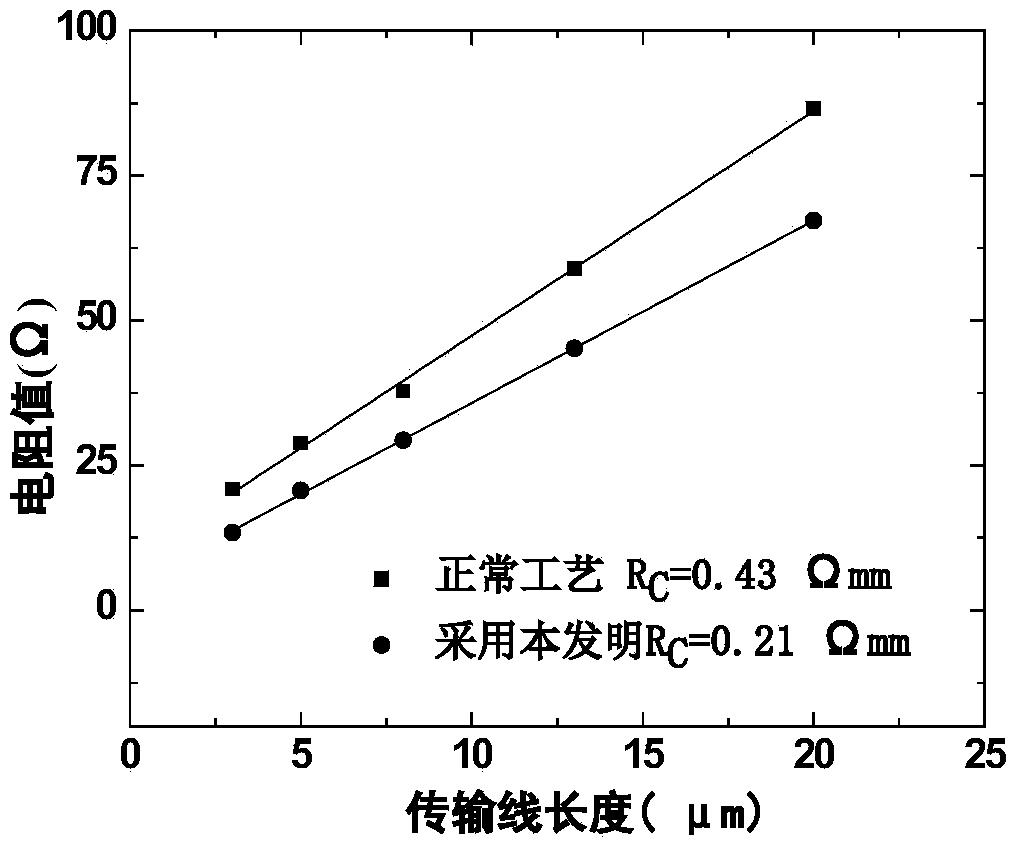

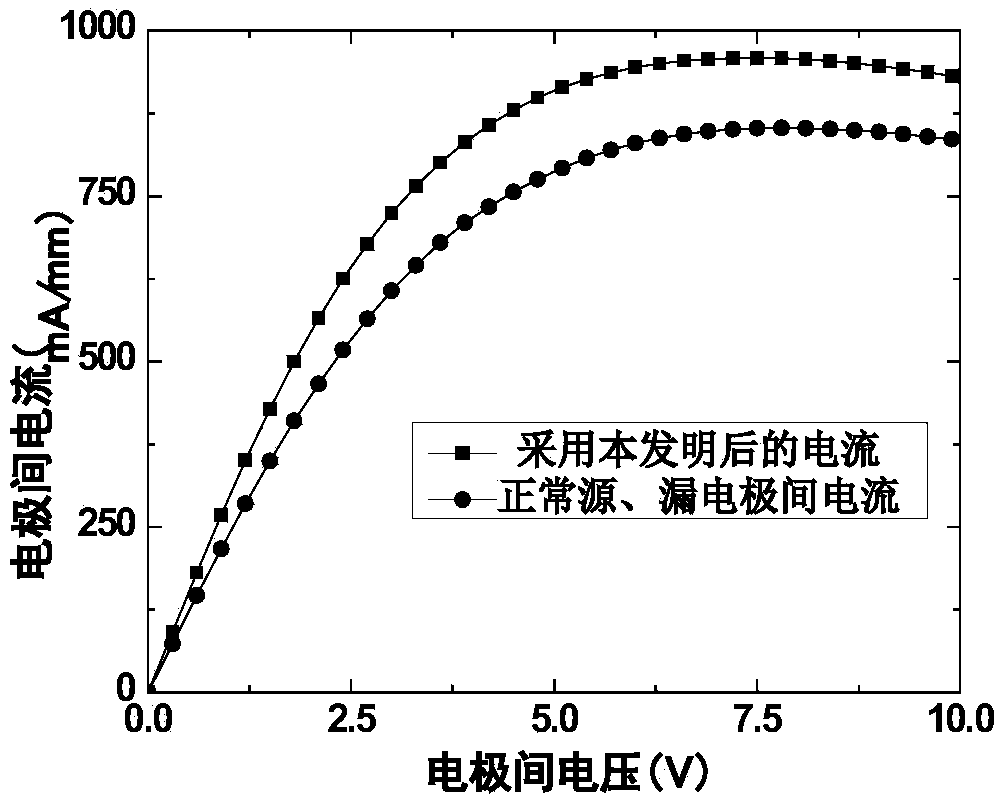

Method for manufacturing AlGaN-GaN heterojunction ohmic contact

InactiveCN103972069AReduce contact resistanceIncrease contact areaSemiconductor/solid-state device manufacturingSemiconductor devicesHeterojunctionElectrical resistance and conductance

The invention discloses a method for manufacturing AlGaN-GaN heterojunction ohmic contact. The problems that in the prior art, contact resistance is large, the process is complex, and cost is high are mainly solved. The method comprises the manufacturing steps that (1), photoetching is carried out on the surface of AlGaN-GaN heterojunction, an etching mask with a plurality of through holes on an ohmic electrode region is obtained, and the sum of the areas of the exposed parts of the through holes is 15 percent to 45 percent of the area of an ohmic electrode; (2), etching hole digging with the depth of 5 nm to 15 nm is carried out on AlGaN materials exposed out of the through holes of the mask; (3), titanium / aluminum / nickel / gold multilayer metal is deposited on the AlGaN-GaN materials of a source region and a drain region with holes dug; (4), annealing of 800 DEG C to 870 DEG C is carried out on deposited electrode metal, and a source and drain ohmic contact electrode is formed. The method has the advantages that the process is simple and easy to control, and the ohmic contact resistance is low, and the method can be used for manufacturing AlGaN-GaN heterojunction high-frequency high-power high-electronic devices high in work efficiency and high in grain.

Owner:XIDIAN UNIV

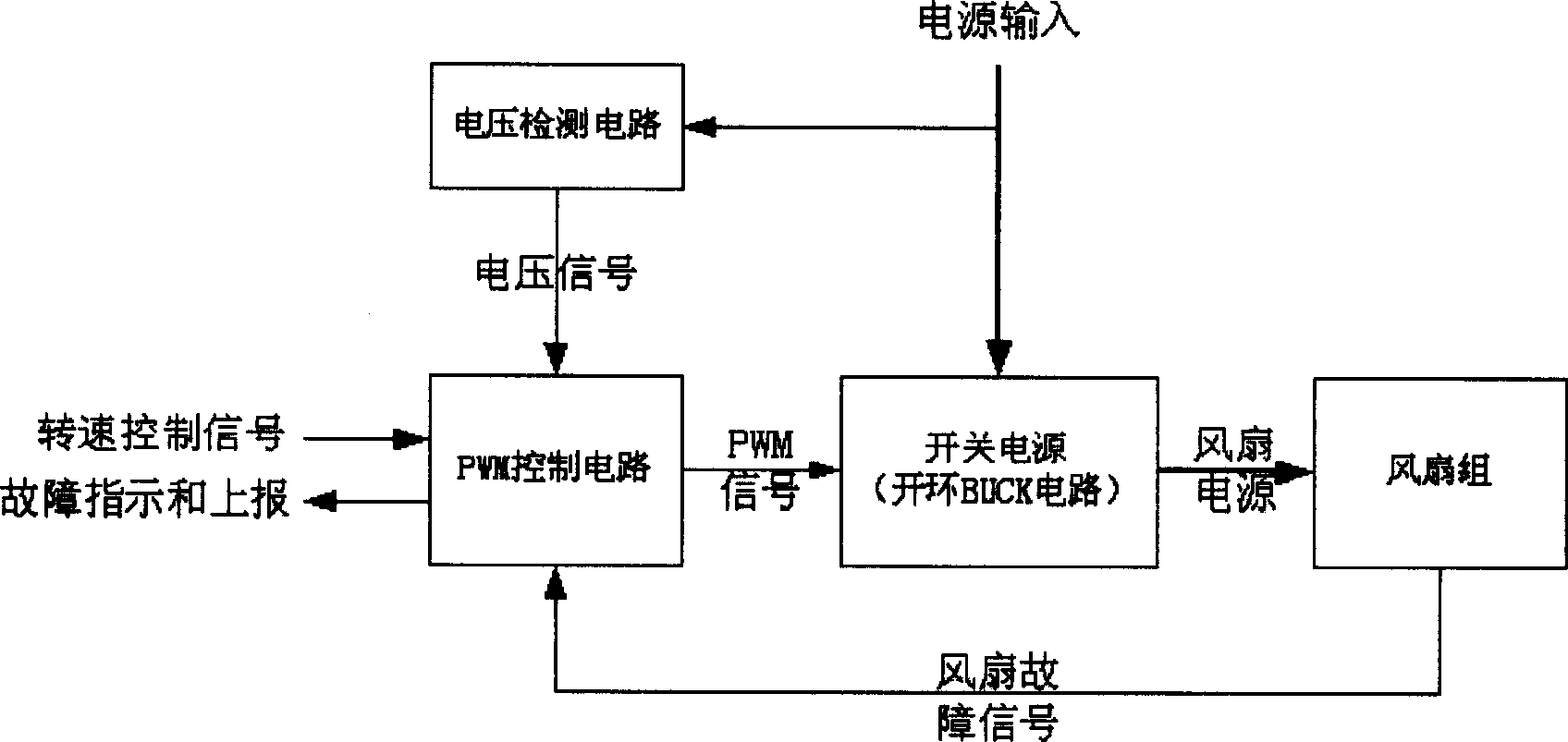

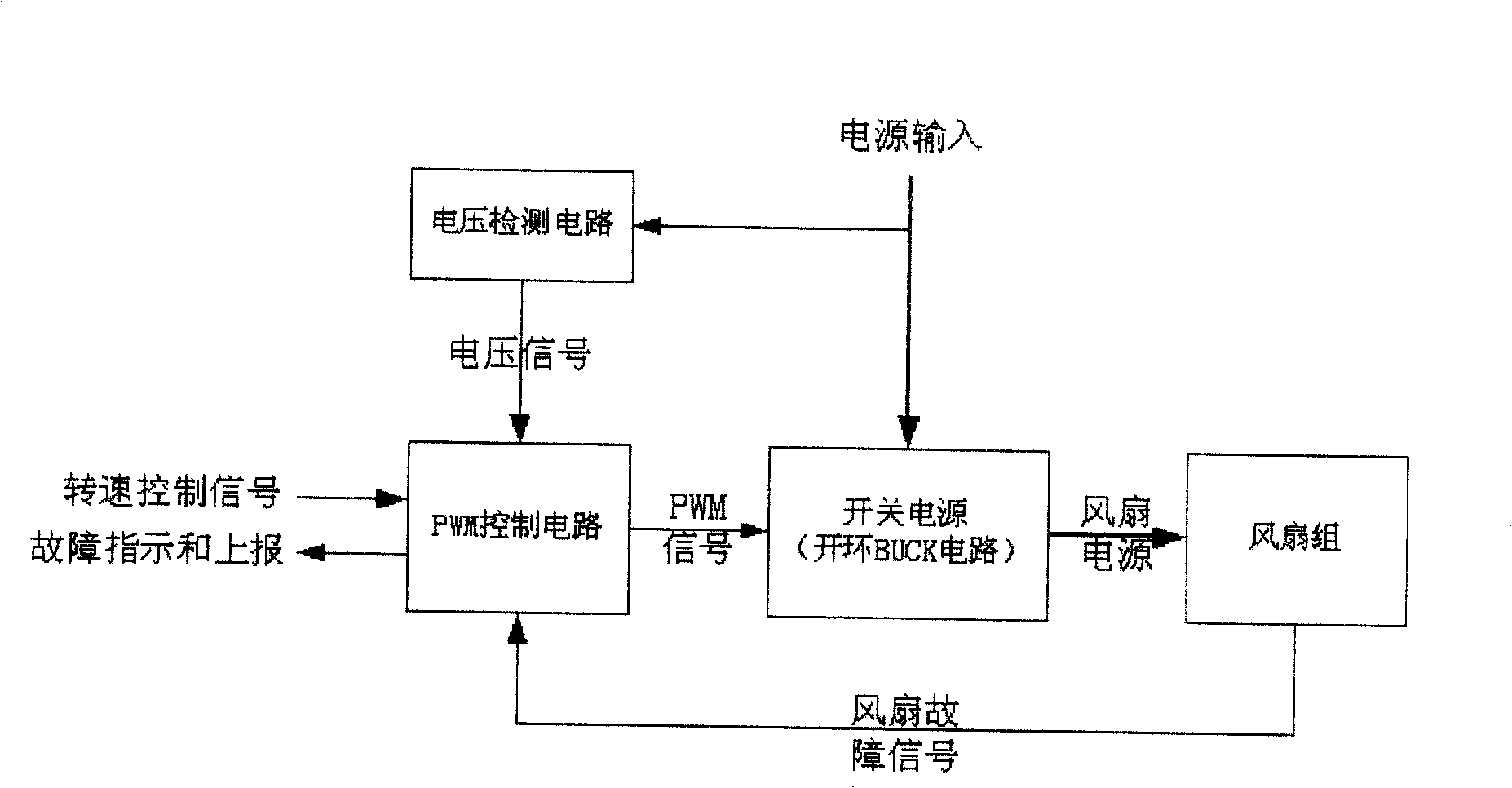

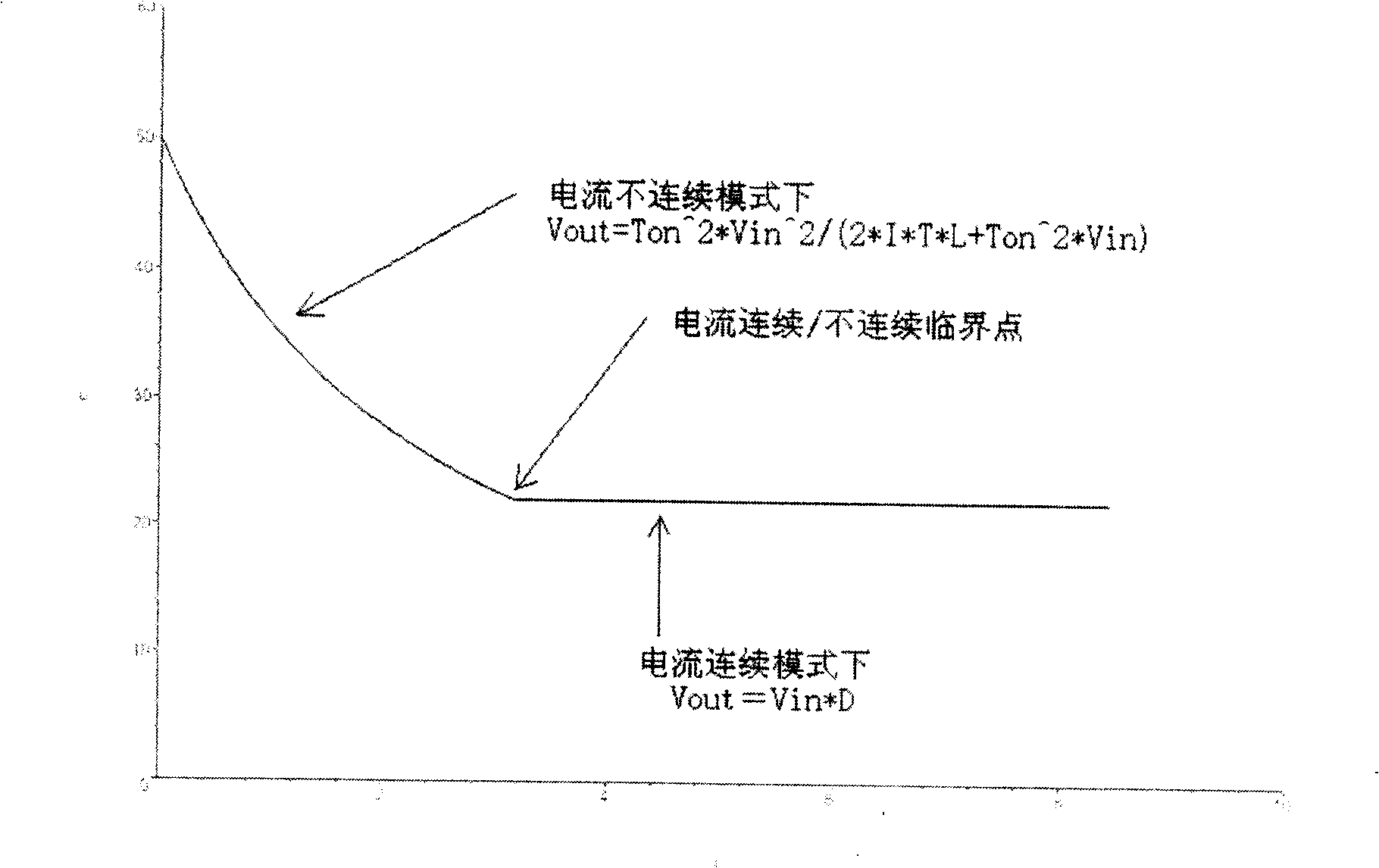

Speed regulating fan system with fault-tolerant capacity

ActiveCN1913334AReduce power consumptionReduce noiseElectric motor controlField or armature current controlElectricityControl signal

This invention relates to a fan regulation system with an error-tolerance ability including an input voltage testing circuit, a PWM circuit, a switch supply circuit and a fan set, in which, the control signal of rotation speed of the system and tested voltage signal control the output of the PWM waveforms, control the switch devices of a switch supply circuit and output a suitable voltage to the fan set, when the fan is tested to be faulty, the duty ratio of the PWm waveform can be adjusted.

Owner:ZTE CORP

Method for melting and digesting free calcium oxide in converter slag

The invention provides a method for melting and digesting free calcium oxide in converter slag. The method comprises the steps that SiO2 and molten blast furnace slag are added into the converter slag by serving as calcium stabilizers at the temperature of 1,450 DEG C or above, and melt blending is conducted according to a certain weight proportion, wherein the adding amount of SiO2 accounts for 8%-50% of the amount of the treated converter slag, the adding amount of the molten blast furnace slag accounts for 30%-100% of the amount of the treated converter slag, SiO2 and the molten blast furnace slag can be added in an echelon mode or added simultaneously, and constant-temperature digesting is conducted for at least 5 minutes in each echelon of the digesting process, so that full and uniform mixing is guaranteed, entire melt blending is completed within 30 minutes, and water cooling or air cooling can be adopted as the cooling mode. According to the method, the content of free calcium oxide in the improved molten mixed slag reaches the national standard, w(CaO) / w(SiO2) is moderate, the size stability is good, comprehensive resource utilization of solid metallurgy waste is achieved, and more ways are developed for energy saving and consumption reducing of a metallurgy enterprise.

Owner:UNIV OF SCI & TECH LIAONING

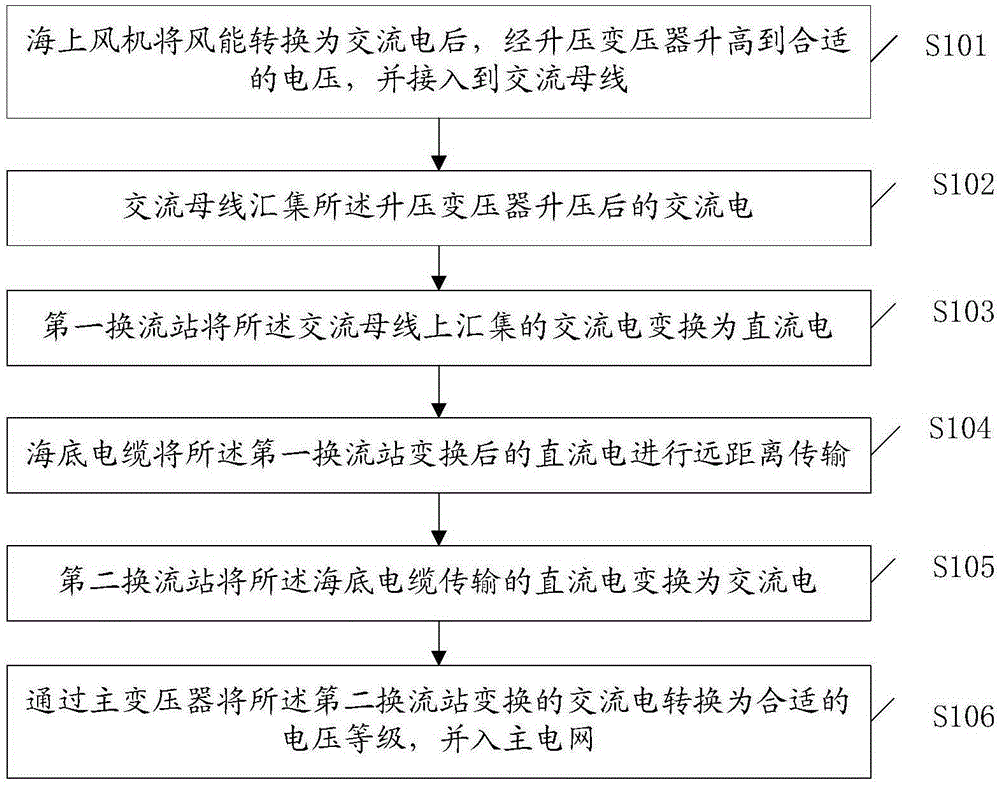

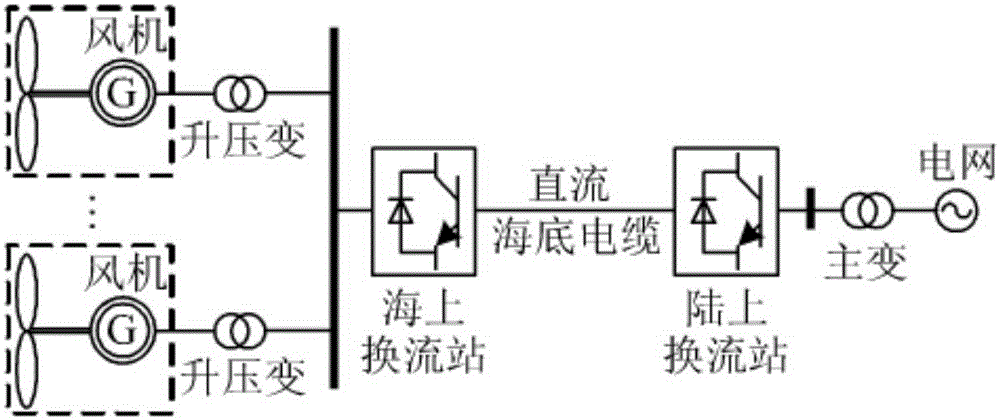

Offshore wind turbine grid connection method and system

InactiveCN105207257AReduce line costReliable operationElectric power transfer ac networkSingle network parallel feeding arrangementsElectric fieldPower grid

The invention discloses an offshore wind turbine grid connection method. The method includes the steps that after an offshore wind turbine converts wind energy into alternating current, the alternating current is boosted to proper voltage through a boosting transformer and connected to an alternating current bus; the alternating current bus collects the alternating current boosted by the boosting transformer; an offshore convertor station converts the alternating current collected on the alternating current bus into direct current; a submarine cable transmits the direct current converted by the offshore convertor station in a long distance; a land convertor station converts the direct current transmitted through the submarine cable into alternating current; a main transformer converts the alternating current converted through the land convertor station into a proper voltage grade, and the alternating current is connected into a main power grid. The invention further discloses an offshore wind turbine grid connection system. The problems existing in grid connection of an offshore wind plant with the long distance and large capacity are solved.

Owner:NANJING NARI GROUP CORP +1

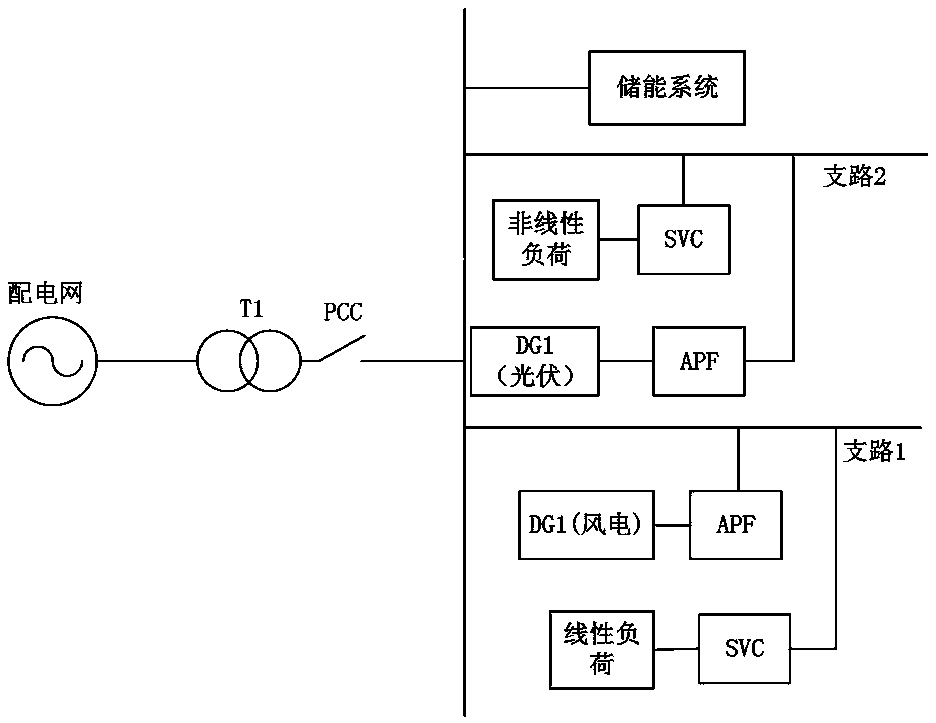

APFs and SVCs combined power quality control method based on micro-power grid energy storage system

InactiveCN108075491ARealize unionGood effectFlexible AC transmissionActive power filteringBusbarPower Balance

The invention relates to an APFs and SVCs combined power quality control method based on a micro-power grid energy storage system. A micro-power grid busbar is connected with an energy storage system,loads, SVCs and a distributed power supply device; the energy storage system is composed of a PCS and an energy storage battery, and the energy storage battery achieves energy exchange with the micro-power grid through the PCS and outputs a proper amount of active power and reactive power to ensure the power balance of the micro-power grid from the system level, so that the system voltage and frequency are maintained relatively stable; the PCS is connected to the micro-power grid busbar; the loads include the linear load and the non-linear load, and both loads are connected to two branches through the corresponding SVCs respectively; the distributed power supply device includes a solar photovoltaic plate and a wind power generation device, and the solar photovoltaic plate and the wind power generation device are connected to two branches through corresponding parallel-type APFs respectively. Through overall coordinated use of the energy storage system, the APFs and the SVCs, the battery energy storage system not only can effectively maintain the power balance of the micro-power grid, but also can improve the power quality of the micro-power grid, and the stable operation of the system in various states is achieved.

Owner:JIANGSU FRONT NEW ENERGY +1

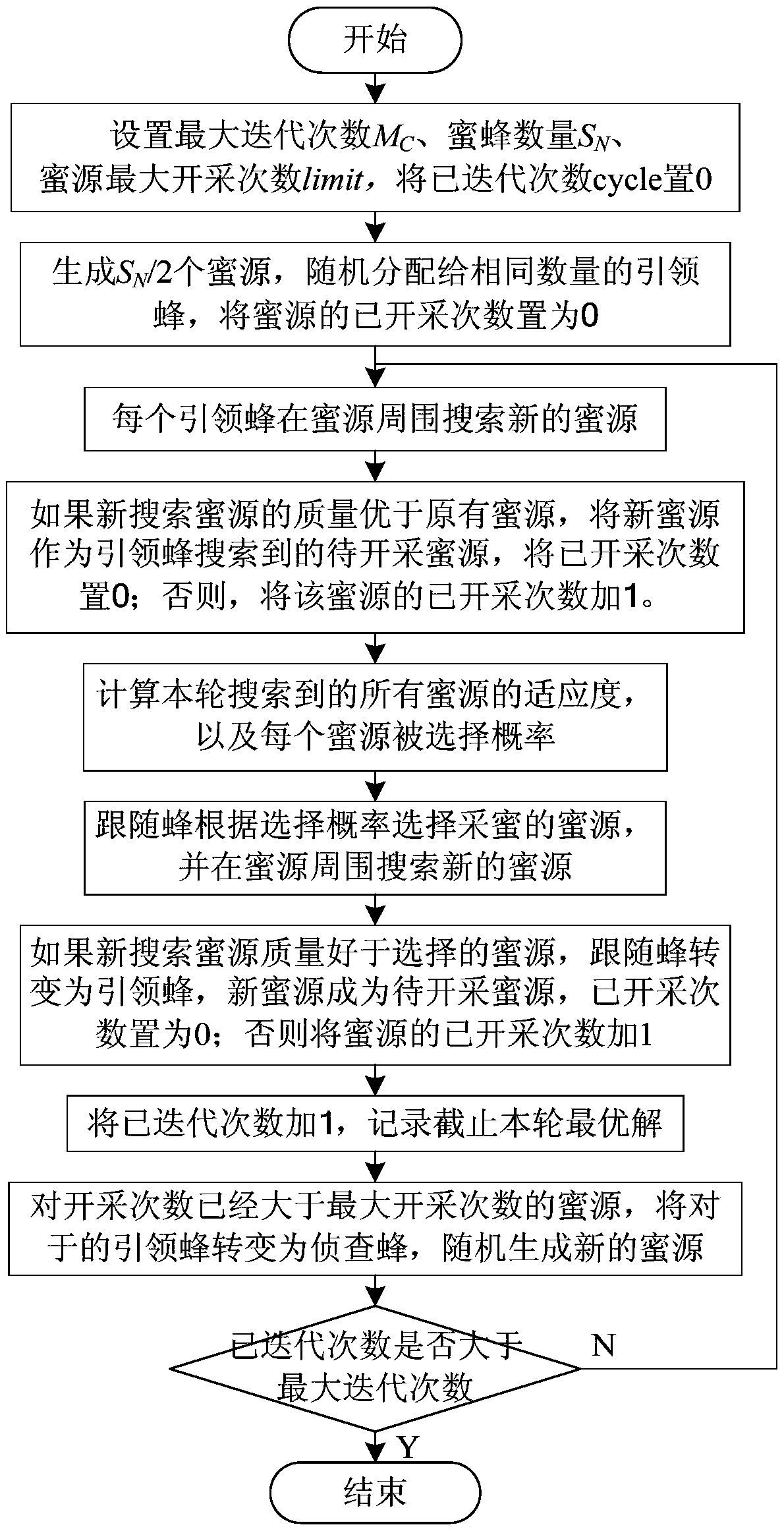

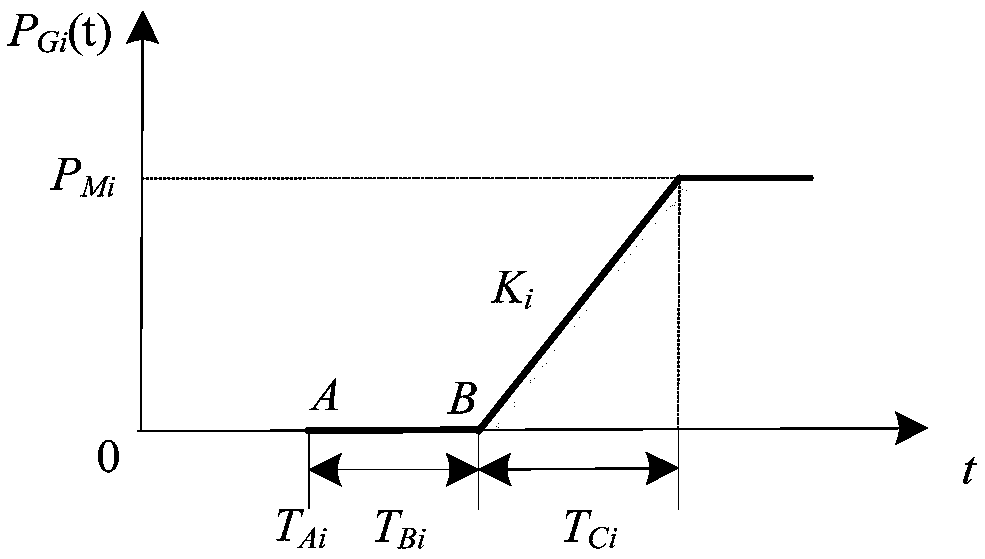

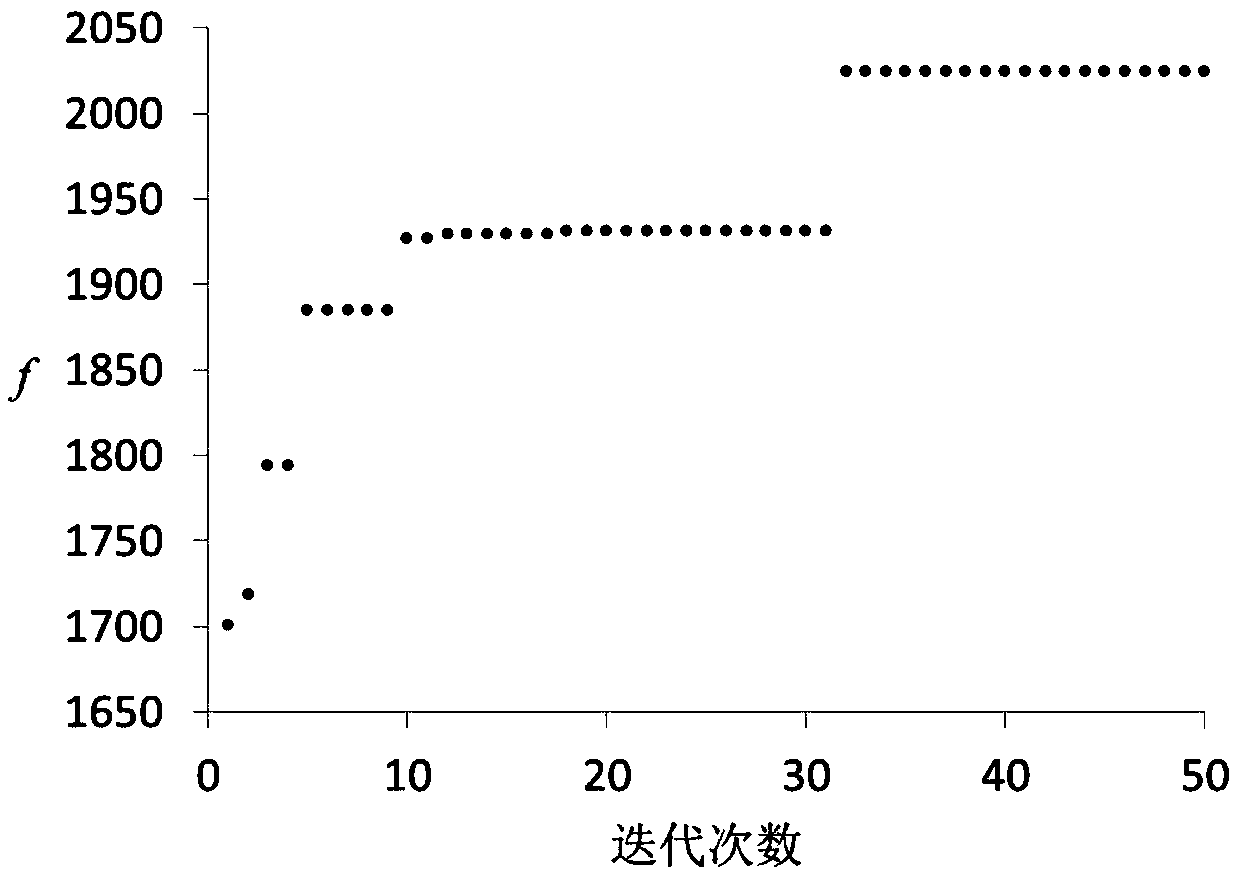

Direct current convertor station containing power supply recovery route optimization method based on artificial bee colony algorithm

InactiveCN105529701AImprove stabilityPromote recoveryContigency dealing ac circuit arrangementsArtificial lifeLocal optimumElectricity

The invention discloses a direct current convertor station containing power supply recovery route optimization method based on an artificial bee colony algorithm. The maximum ratio between electric energy production and recovery time in a recovery process of a to-be-recovered power supply is taken as the optimization target; a partial optimized power transmission path of a to-be-started power supply is solved based on a Dijkstra shortest route algorithm; and a global optimal recovery route is solved based on the artificial bee colony algorithm. The power supply recovery route optimization method comprises the steps of 1, initializing power supply recovery sequence codes; 2, searching a shortest route from an electrified system to the to-be-recovered power supply by adopting the Dijkstra algorithm; 3, performing technological verification on the to-be-recovered power supply and the recovered path of the to-be-recovered power supply; and 4, optimizing the power supply recovery sequences based on the artificial bee colony algorithm. According to the method, a universal mode for optimizing the power transmission route of a power grid containing the direct current convertor station is proposed; the optimization is realized based on the advantages of high rate of convergence and strong global searching capability of the artificial bee colony algorithm; and the optimization method is of great significance for a black-start scheme after blackouts.

Owner:NANJING UNIV OF SCI & TECH +3

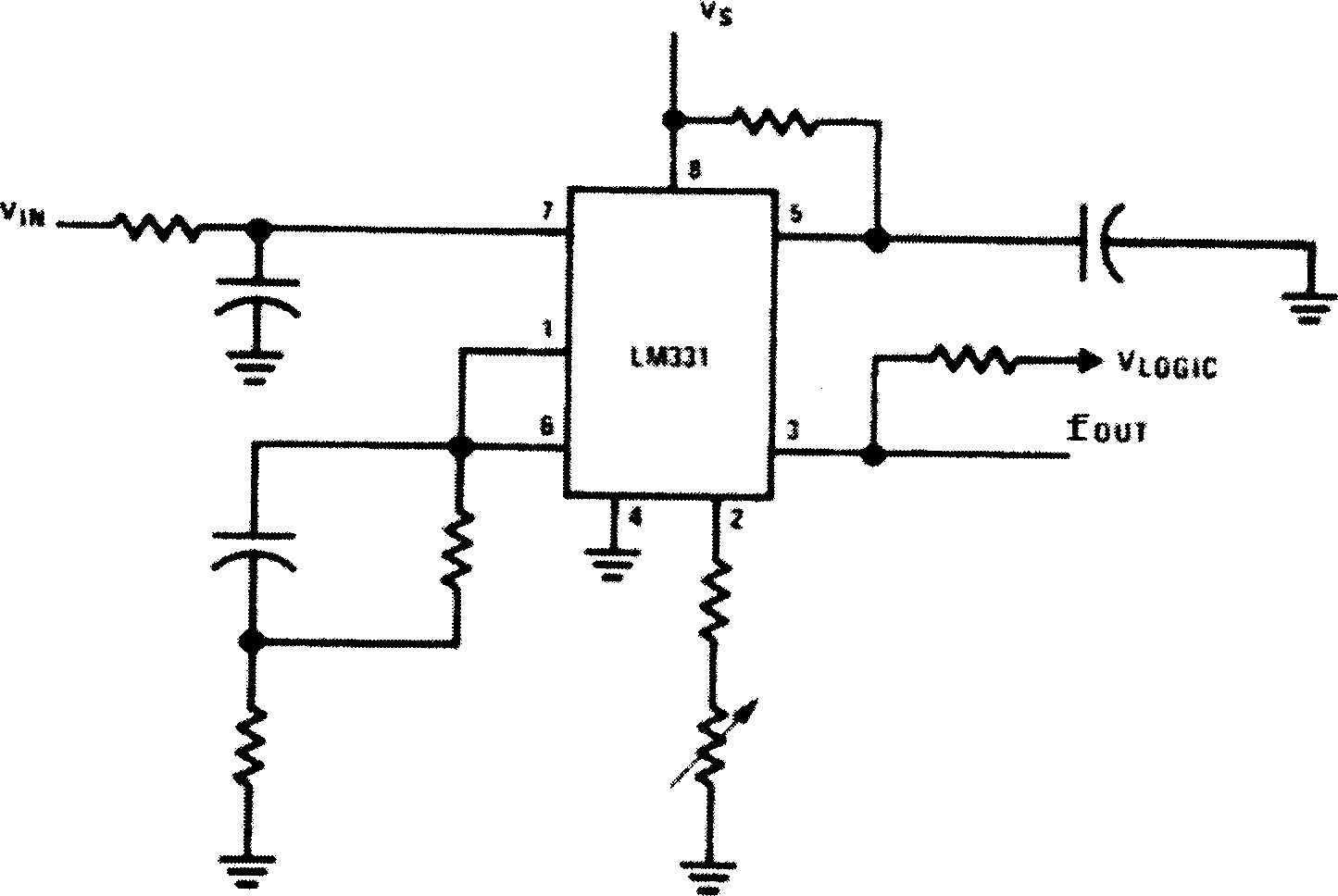

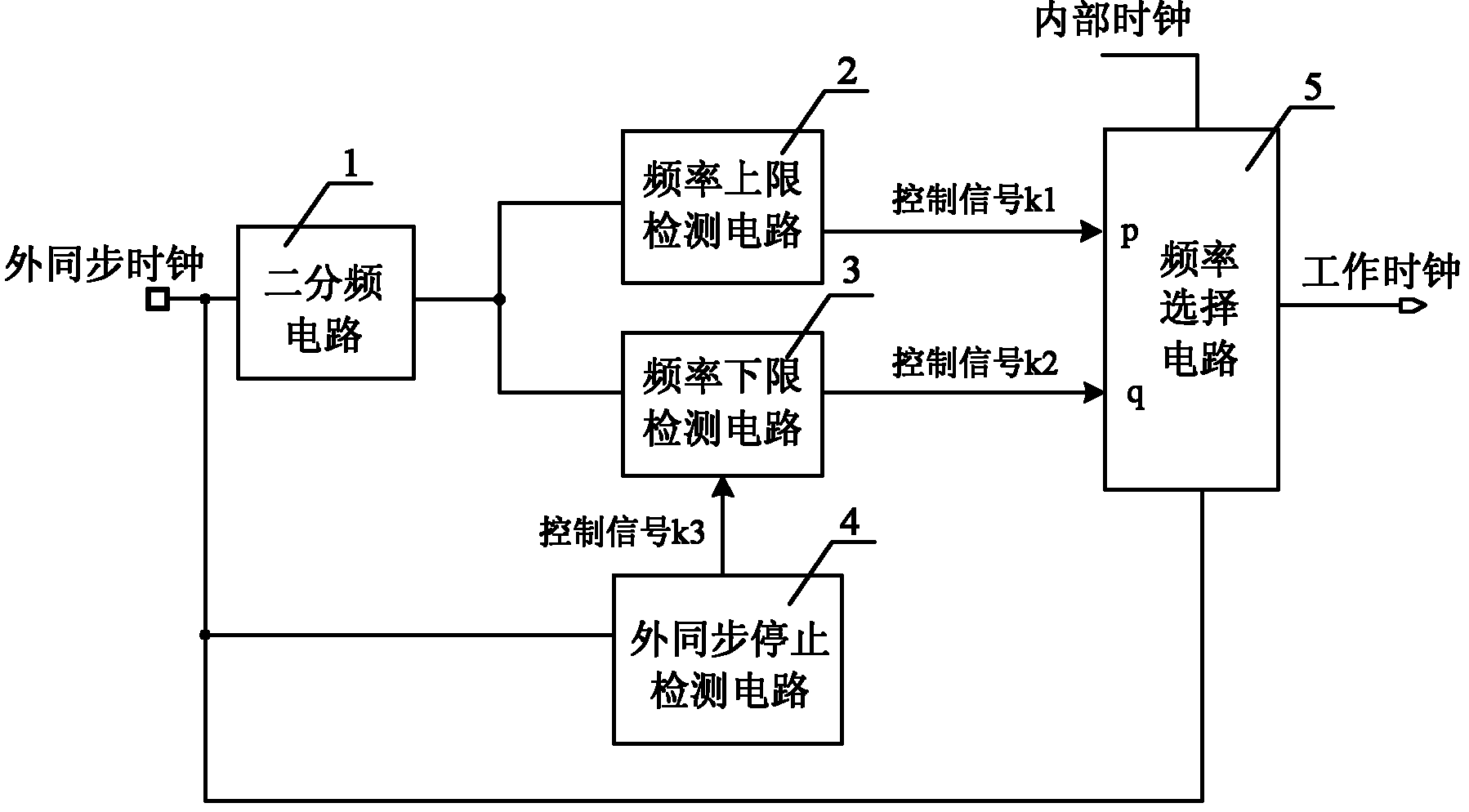

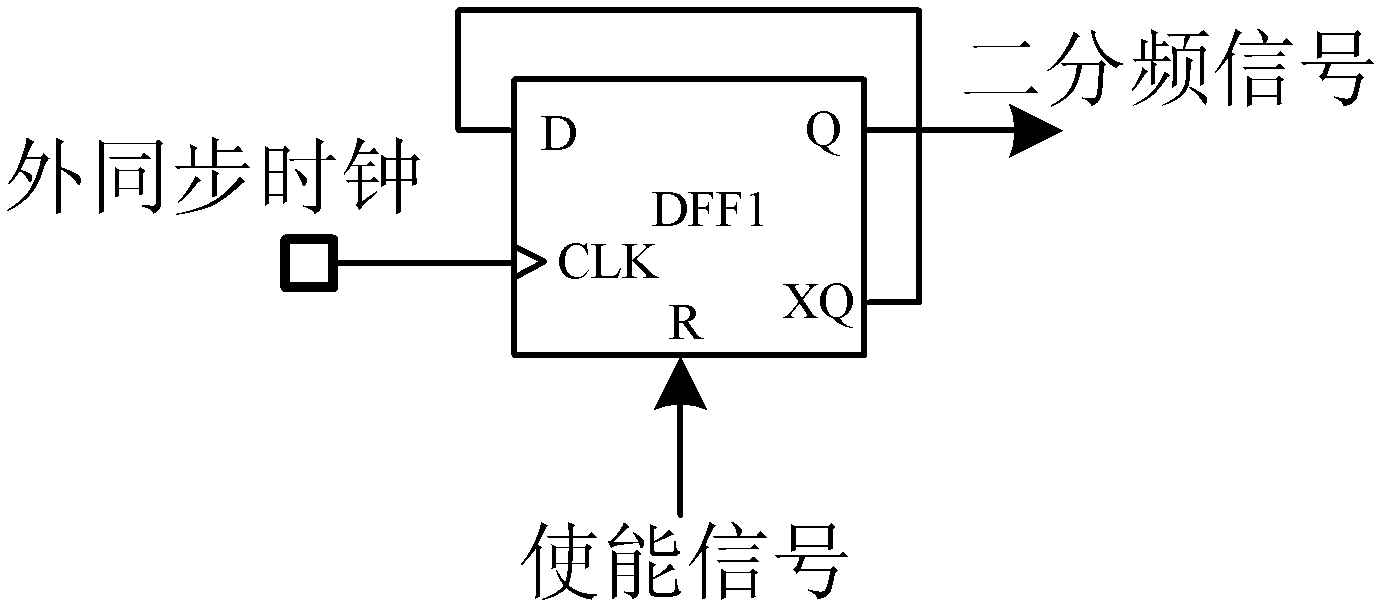

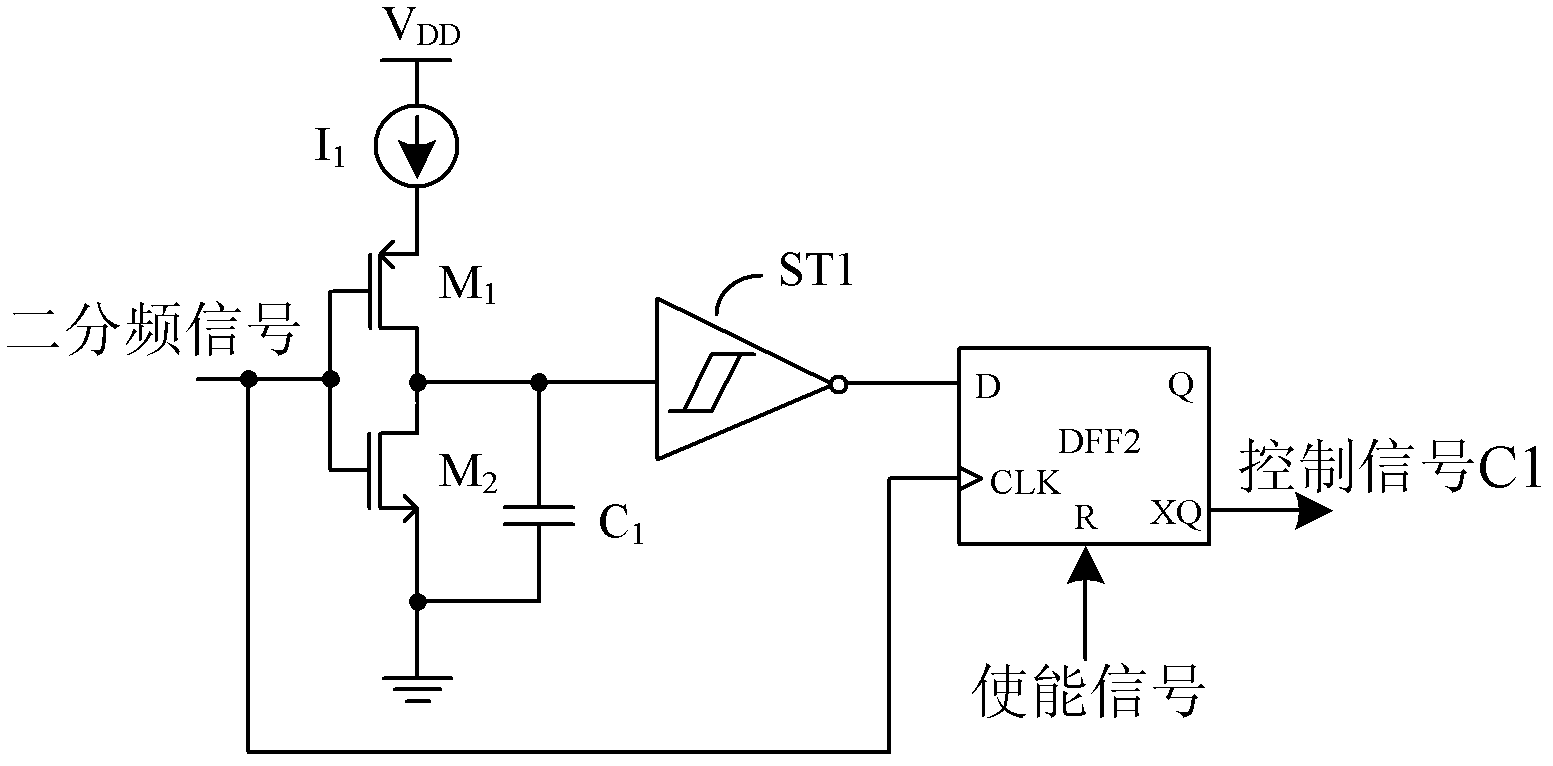

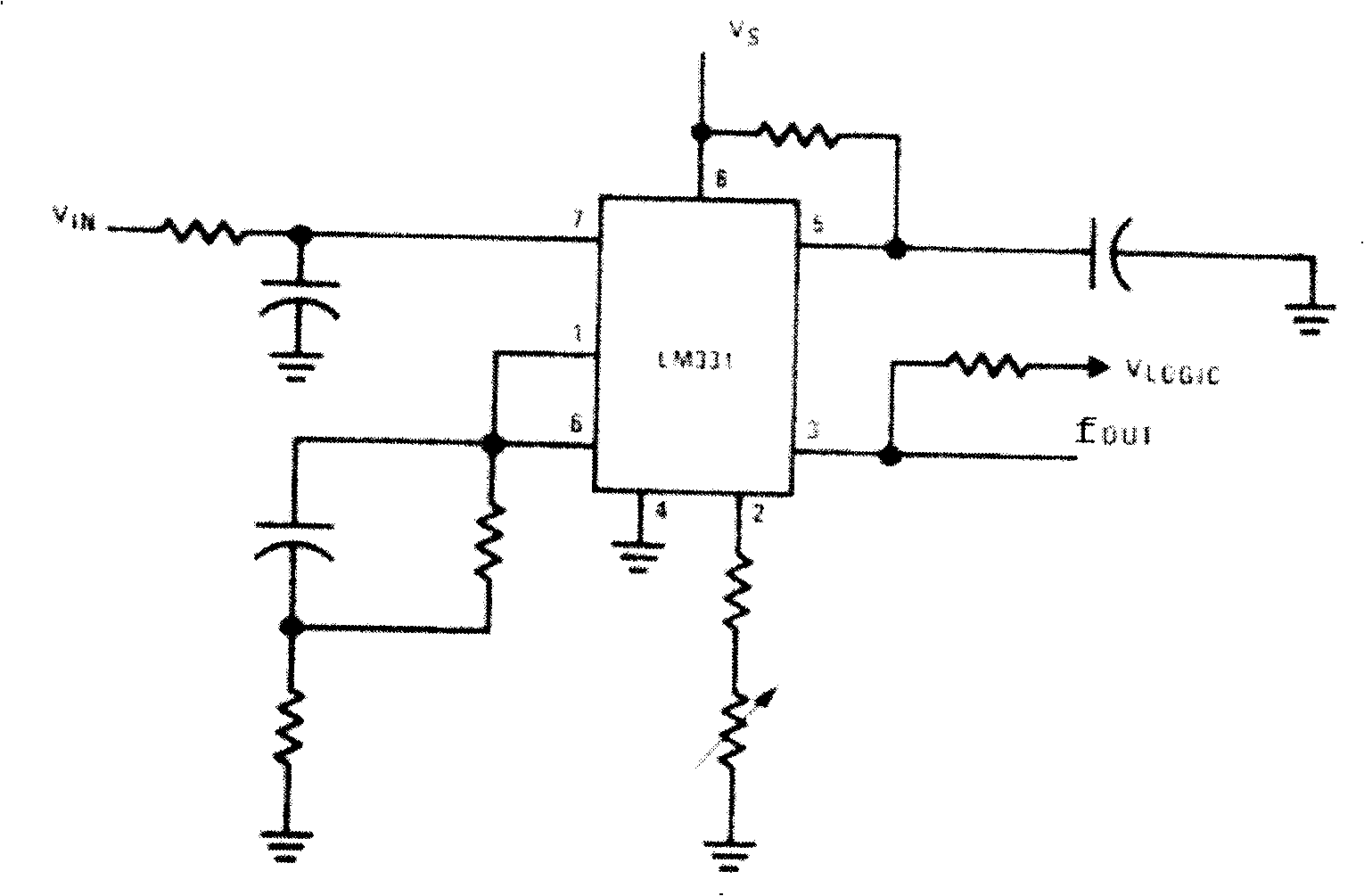

External clock synchronization circuit of switching power supply

ActiveCN102427364ASimple structureNo stability issuesPulse automatic controlPower conversion systemsLower limitControl signal

The invention discloses an external clock synchronization circuit of a switching power supply. In the prior art, a circuit structure is complex, external synchronization time is long and frequency jitter exists. By using the external clock synchronization circuit of the switching power supply, the above disadvantages can be overcome. The circuit comprises: a frequency-halving circuit, a frequency cap detection circuit, a lower limit frequency detection circuit, an external synchronization stopping detection circuit and a frequency selection circuit. An external synchronous clock is connected to the lower limit frequency detection circuit and the frequency cap detection circuit through the frequency-halving circuit so as to detect whether the external synchronous clock frequency is in a preset numerical interval. The lower limit frequency detection circuit is connected with the synchronization stopping detection circuit so as to determine whether the external synchronous clock is removed. Control signals output by the lower limit frequency detection circuit and the frequency cap detection circuit are connected to the frequency selection circuit so that the frequency selection circuit is controlled to select one from an internal clock and the external synchronous clock to output so as to be taken as a working clock of the switching power supply. A circuit structure is simple. The external clock can be rapidly and accurately synchronized and the external clock synchronization circuit of the invention can be applied in various kinds of the switching power supplies.

Owner:深圳德信微电子有限公司

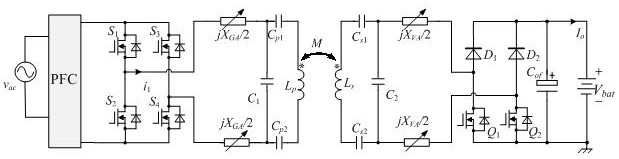

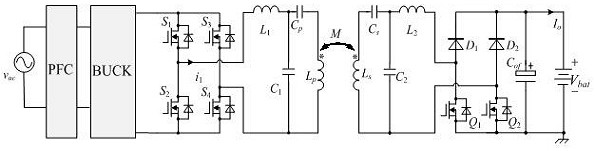

Wireless electric energy transmission device for improving system interoperability and control method

ActiveCN112994269AImprove interoperabilityHigh Efficiency Power TransmissionBatteries circuit arrangementsCharging stationsMode controlHemt circuits

The invention discloses a wireless electric energy transmission device for improving system interoperability and a control method. The device comprises a power factor correction circuit, an inverter circuit, a resonance unit, a rectification circuit, a filter circuit and a load which are sequentially cascaded, and also comprises a source side regulator, an inverter mode controller and a load side regulator. By switching the working modes of the inverter circuit and the rectifying circuit, with a bus voltage regulation and controllable rectifying technology, interoperation and high-efficiency electric energy transmission of the IPT system are realized, and multi-gear power level transmission requirements can be met in a wide load range and a wide coupling coefficient range. According to the invention, the interoperation requirements of three types of power levels and three types of energy transfer distances of EV WPT system vehicle-mounted end equipment are met by using one set of device, additional circuit elements do not need to be added in the aspect of circuit topology, the system cost and the installation space are effectively reduced, and the cost performance is high.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS +1

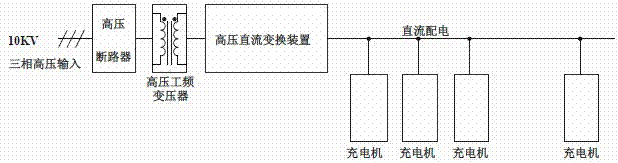

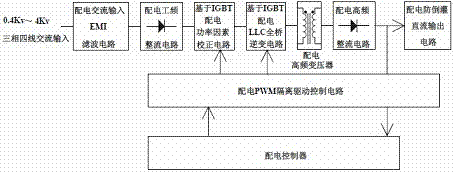

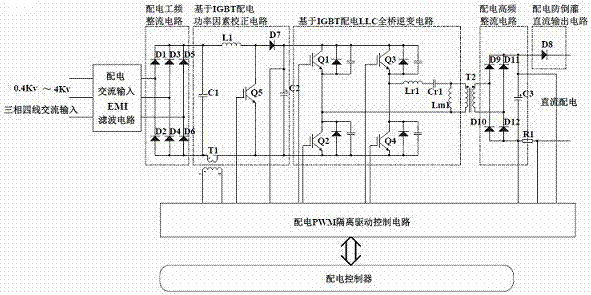

High withstand voltage IGBT DC power distribution based electric vehicle charging station

InactiveCN107069891ASolve the rectificationAvoid correctionCharging stationsMobile unit charging stationsTransformerPower factor

The invention discloses a high withstand voltage IGBT DC power distribution based electric vehicle charging station. The high withstand voltage IGBT DC power distribution based electric vehicle charging station comprises a high-voltage circuit breaker, a high-voltage power frequency transformer, a high-voltage DC conversion device and a charger. A three-phase high-voltage input voltage is connected with the high-voltage power frequency transformer through the high-voltage circuit breaker; the output end of the high-voltage power frequency transformer is connected with the high-voltage DC conversion device; and the high-voltage DC conversion device converts a three-phase high-voltage input AC power into a DC power and then supplies to DC power to the charger. By adoption of the high withstand voltage IGBT, the high-voltage DC conversion device realizes power factor correction, LLC full bridge inversion and a DC power distribution scheme of converting the three-phase high-voltage input AC power into the DC power and then supplying the DC power to the charger; and without power factor correction, the design of the DC charging module is simplified, the power density of the DC charging module is improved, the reliability of the charger is improved and the cost of the charger is reduced. In addition, the high withstand voltage IGBT DC power distribution based electric vehicle charging station increases the device IP protection level, improves the working reliability of the device in an outdoor malicious environment and prolongs the service life of the device.

Owner:GUANGDONG THOUSANDS OF CITIES & CHARGING STATIONS E VEHICLES OPERATING CO LTD

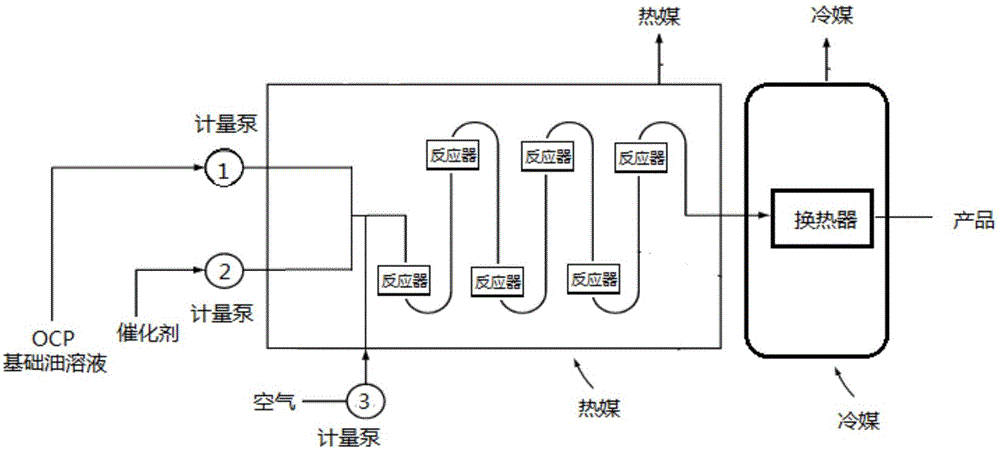

Preparation method of lubricating oil tackifier with high shear resistance

InactiveCN105886073AUnattendedReduce energy consumptionAdditivesChemical reactorInternal combustion engine

The invention relates to a preparation method of a lubricating oil tackifier with high shear resistance. The product quality is effectively controlled by means of an efficient mass transfer and heat transfer microchannel chemical reactor in combination with a thermal catalytic degradation, high-temperature thermal degradation and oxidative degradation combined process, the shear resistance of a product is sufficiently improved, the lubricating oil tackifier can be widely applied to top-grade internal combustion engine oil, hydraulic oil and gear oil products, and the preparation method is simple in process operation, mild in condition and environment-friendly.

Owner:上海时航科技有限公司

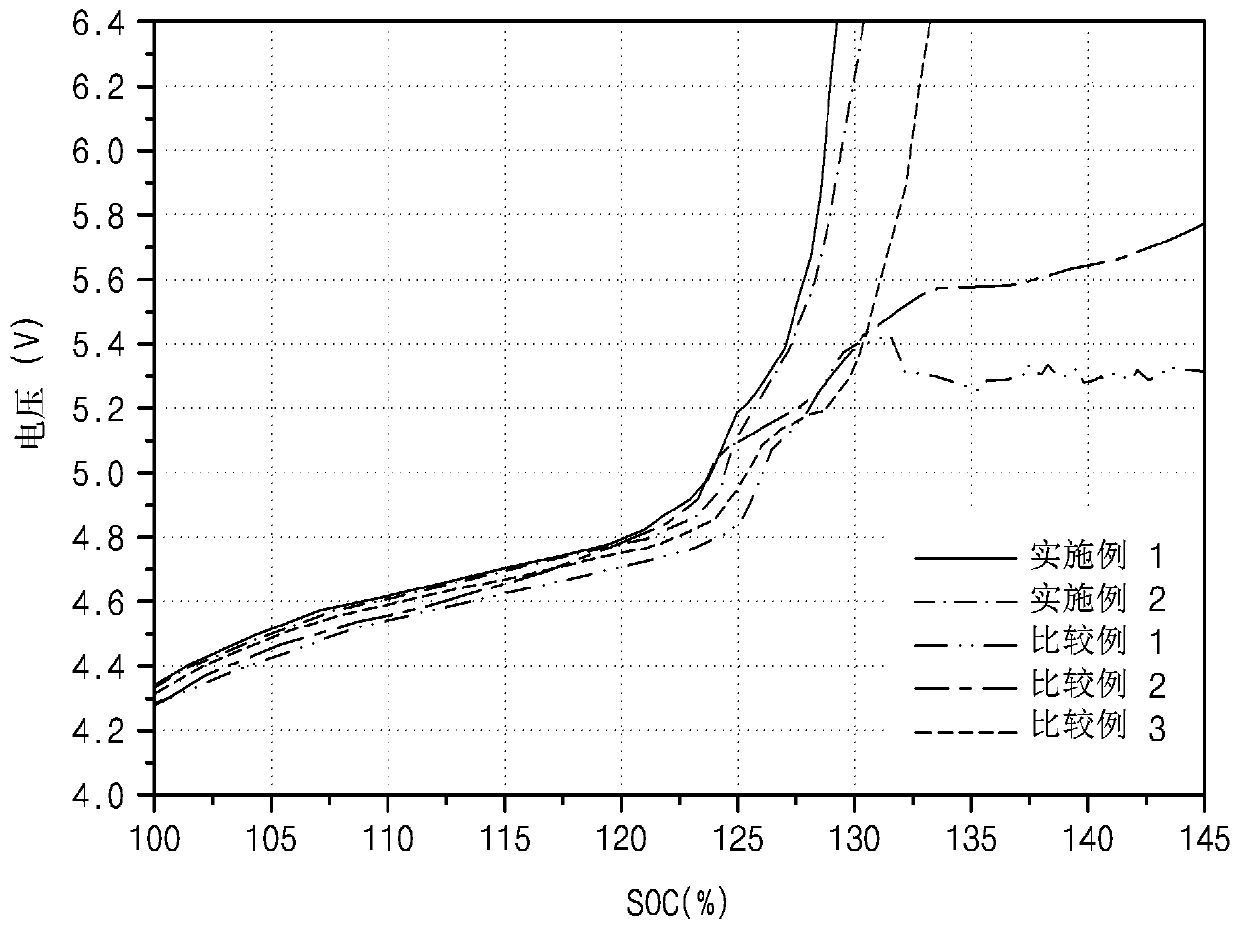

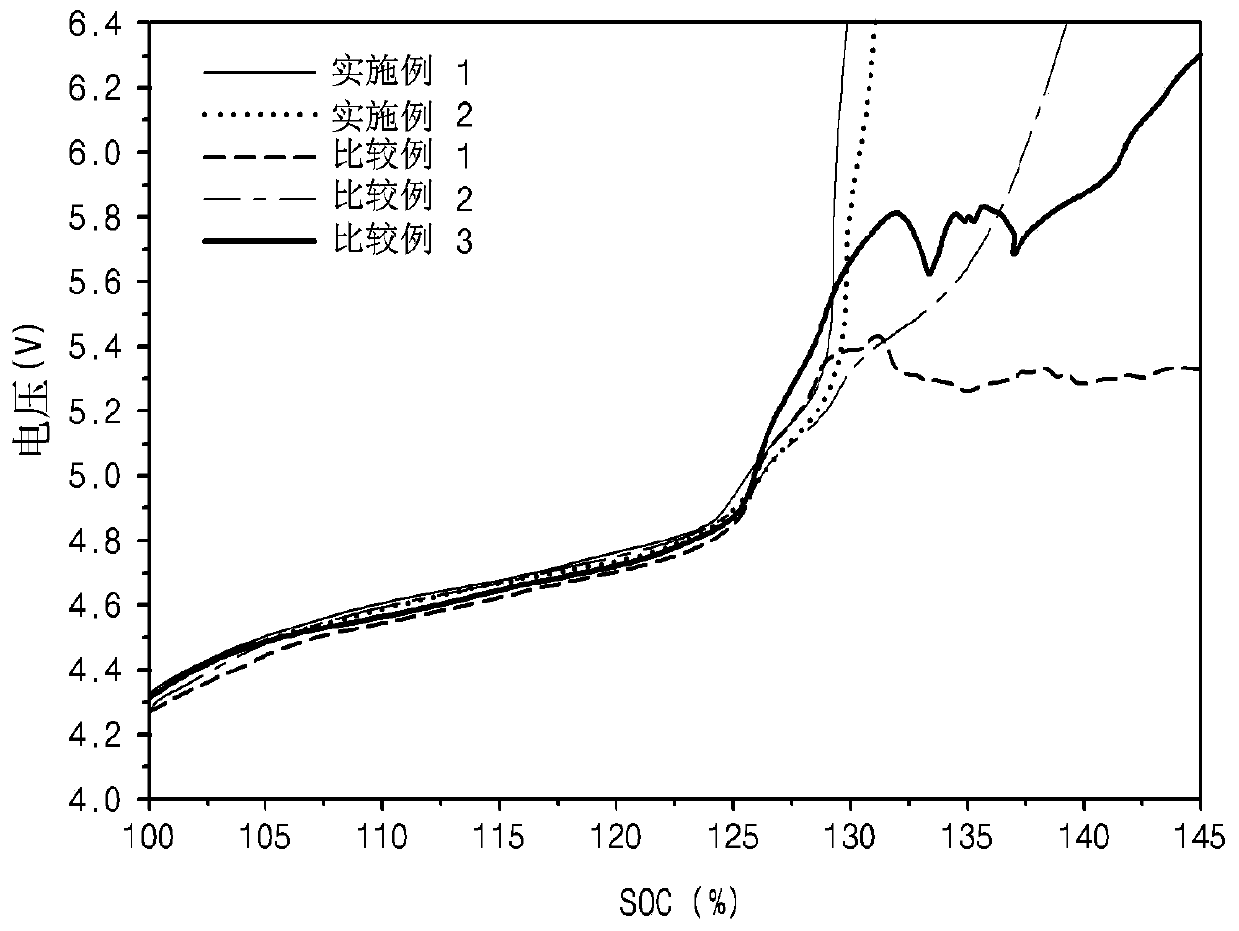

Secondary battery cathode and lithium secondary battery comprising same

ActiveCN110073525AImprove stabilityIncrease energy densityPositive electrodesNon-aqueous electrolyte accumulator electrodesConductive materialsEngineering

The present invention relates to a secondary battery cathode for improving stability upon overcharging and a lithium secondary battery comprising the same and, specifically, to a secondary battery cathode and a lithium secondary battery comprising the same, the secondary battery cathode being a cathode comprising a cathode active material formed on a cathode current collector, wherein the cathodeactive material has a two-layer structure including a first cathode active material layer formed on the cathode current collector and a second cathode active material layer formed on the first cathodeactive material layer, the first cathode active material layer includes a first cathode active material, a conductive material, and a gas generating material for generating gas upon overcharging, andthe second cathode active material layer includes a second cathode active material.

Owner:LG ENERGY SOLUTION LTD

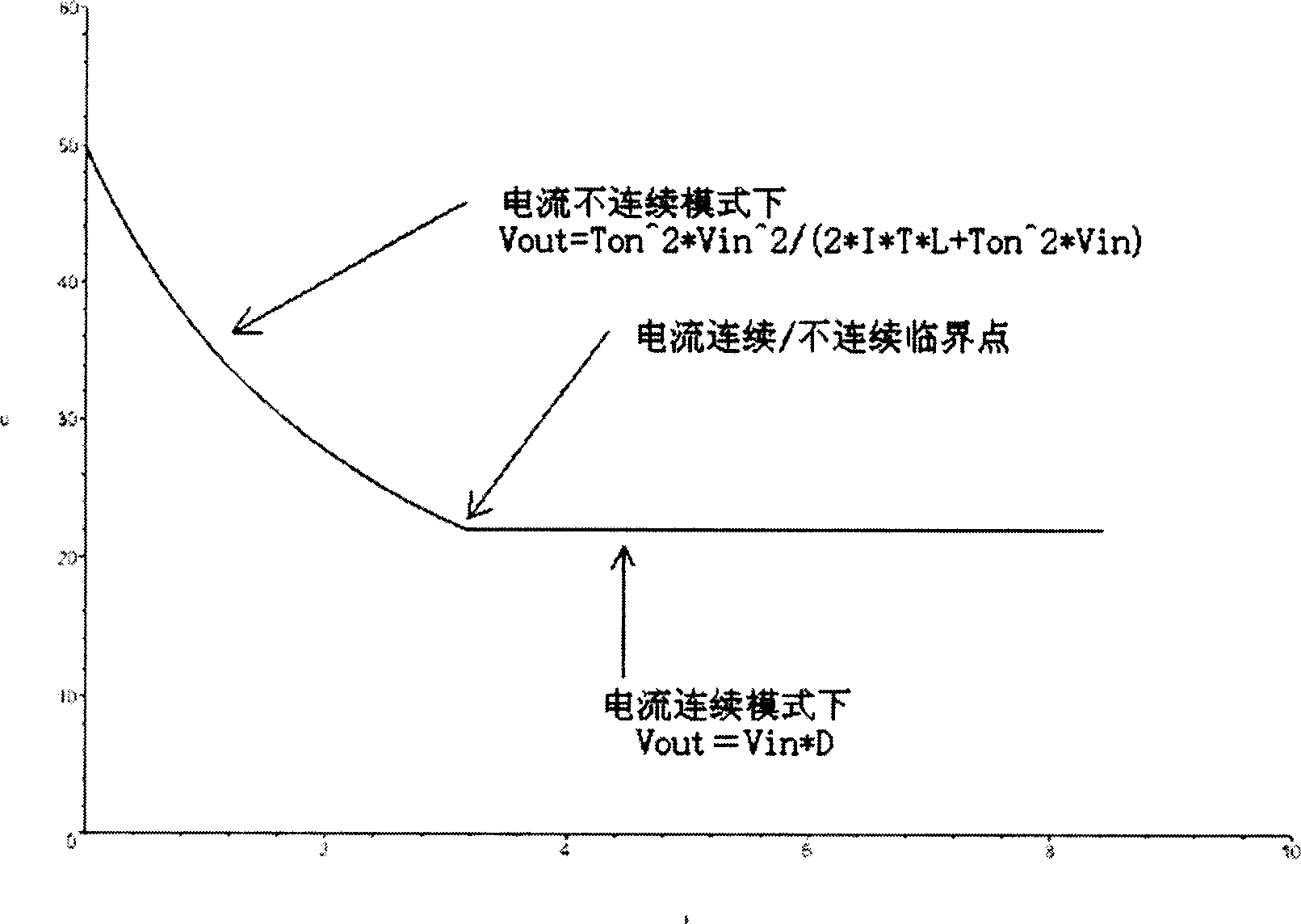

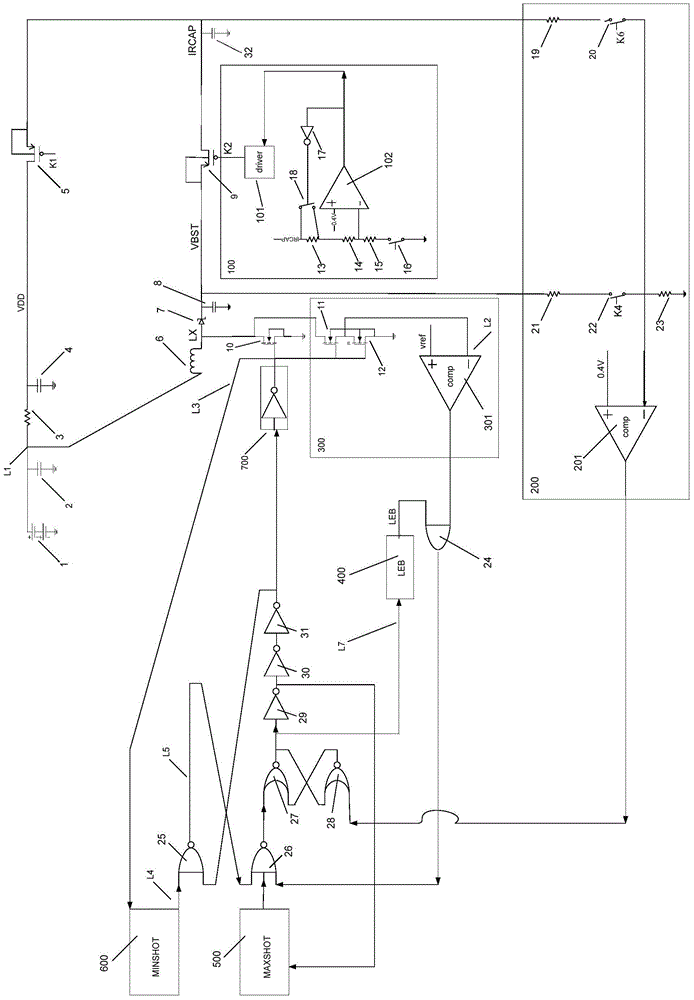

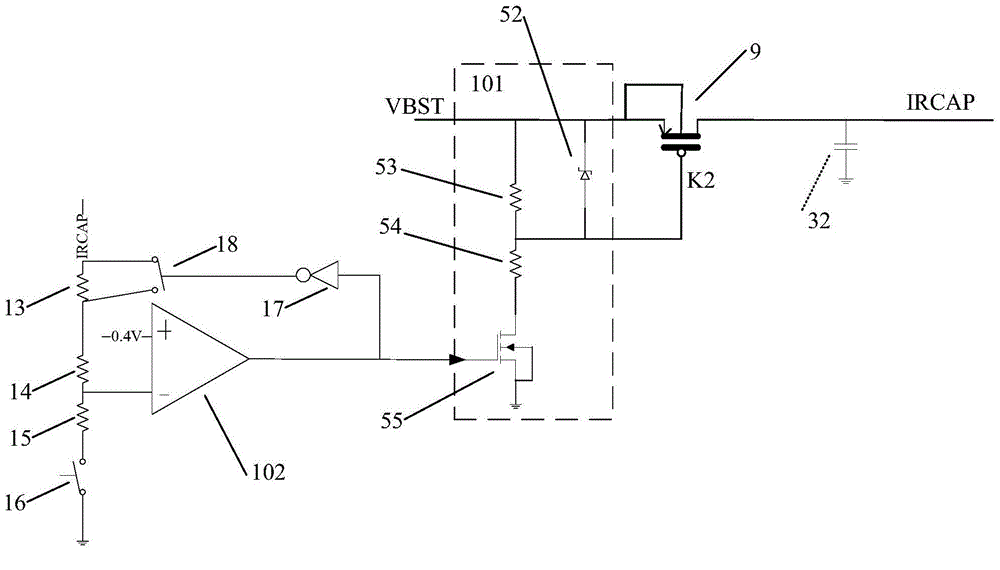

Boosting circuit

ActiveCN104485819ANo stability issuesImprove efficiencyDc-dc conversionElectric variable regulationPower flowComputer module

The invention relates to a boosting circuit. The boosting circuit comprises a bias voltage module, a main boosting module, a driving control module, a voltage feedback module, a current feedback module, a limiting loop and an oscillating circuit. By utilizing the boosting circuit, a novel boosting modulation structure is provided, and two output voltages are achieved on the basis; moreover, the switching pulse period and the switching pulse frequency are automatically adjusted along with the input output voltage and load conditions, the problem of low loop stability is avoided, and the efficiency is higher.

Owner:SHANGHAI BEILING

Signal phase tracking network

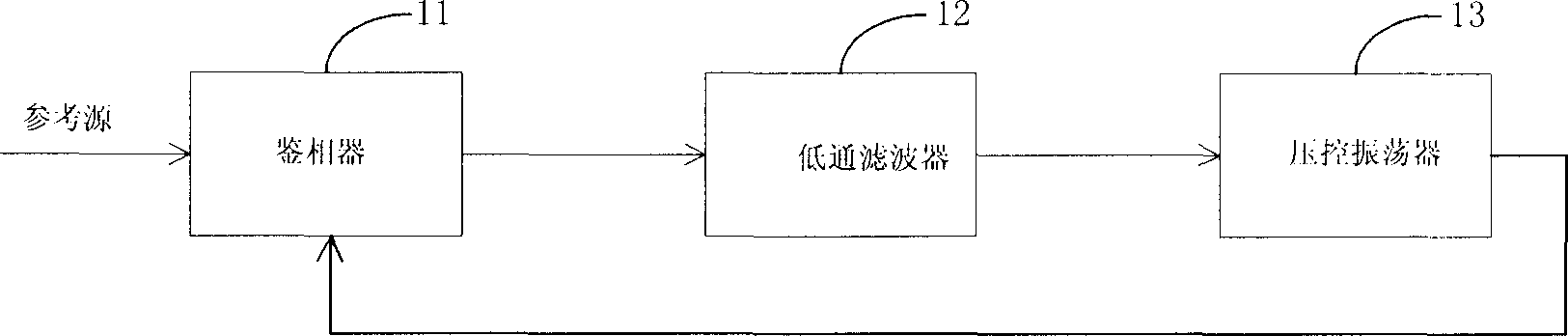

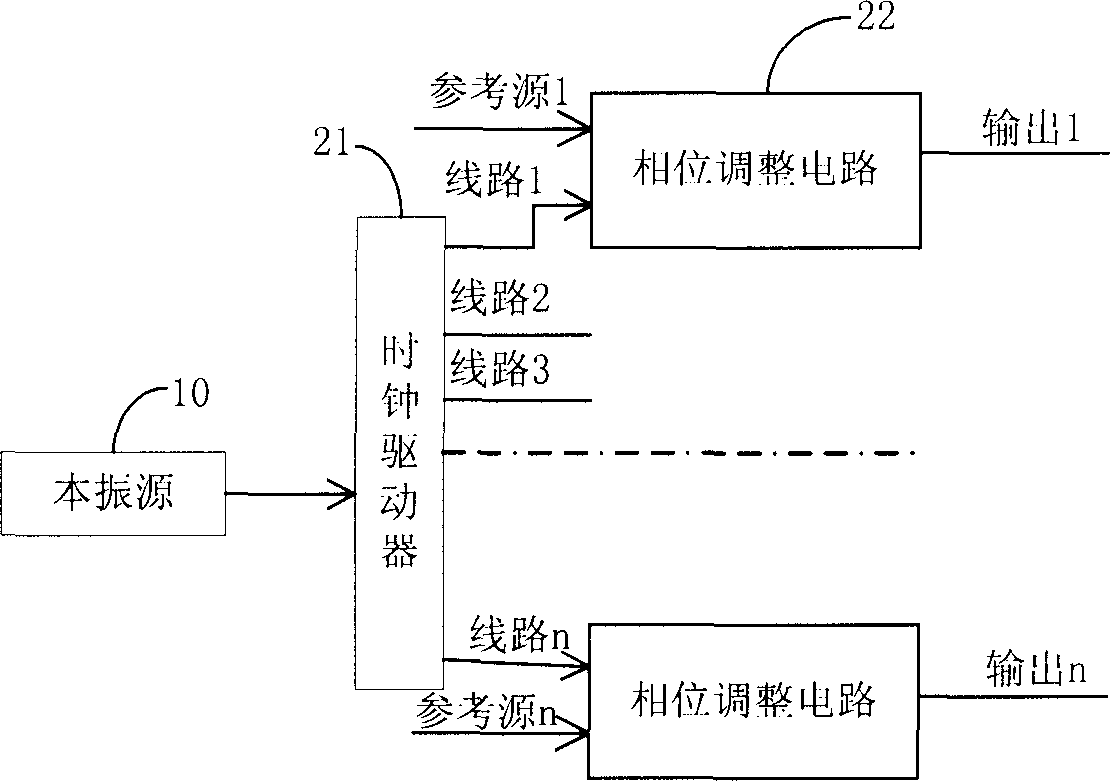

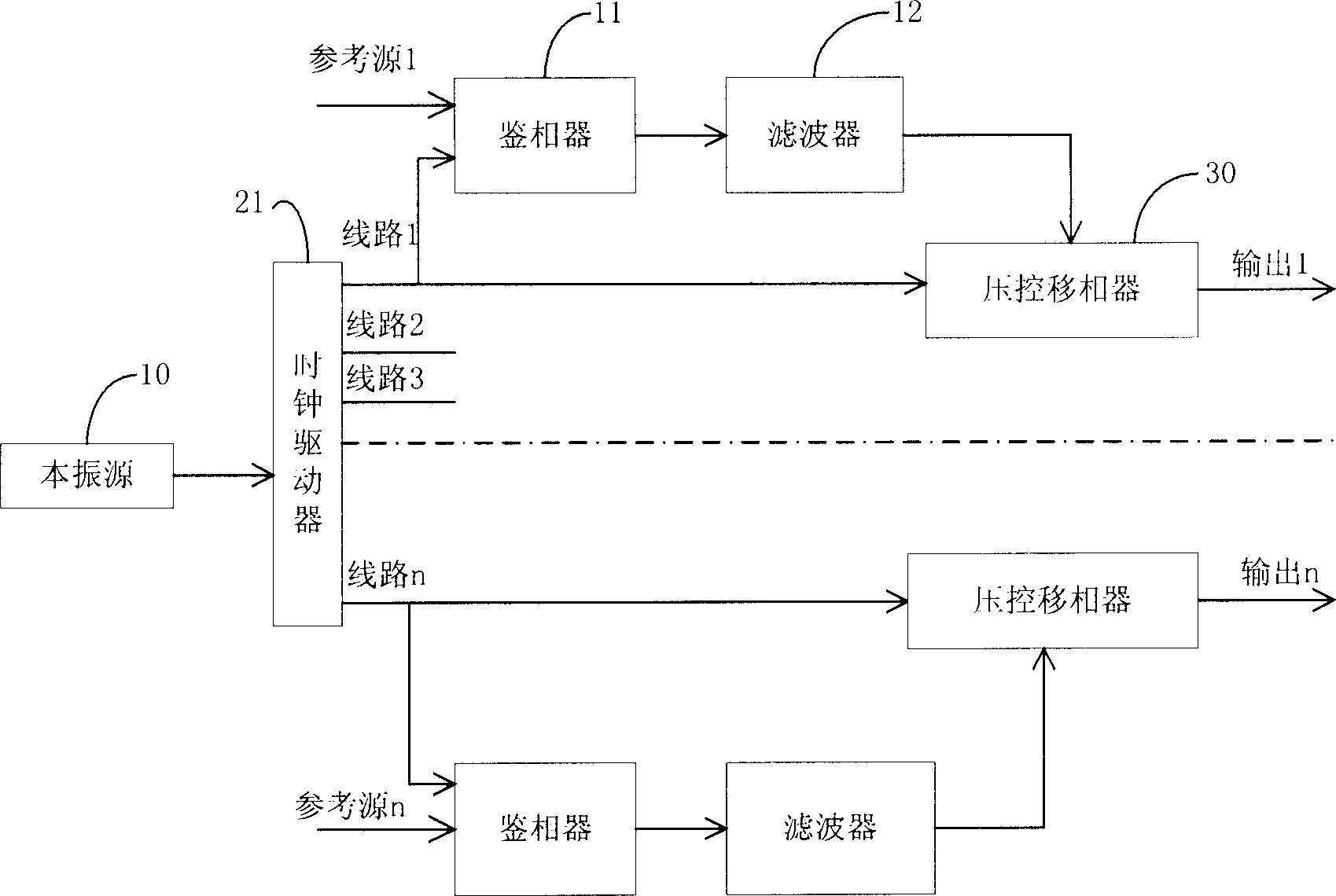

InactiveCN1553592AImprove reliabilityImprove stabilityPulse automatic controlRadio transmissionEngineeringMulti phase

This invention discloses a signal phase tracking network used to track the signal phase of multi reference sources, comprising: the original vibration source providing original vibration signal to track the reference source signal; the clock driver driving original vibration source to output multi signals to track multi corresponding reference source signals; the multi phase adjusting circuits each connect to the signal output end of clock driver, the above phase adjusting circuits are used to track one route reference source signal due to one route signal outputted by original vibration source and adjust the signal phase of origin vibration source in this route according to the result of tracking and checking. The invention provides multi original source signal by the clock driver, so it can track multi reference source signal, because it only uses one original vibration source, so the reliability is improved relatively.

Owner:HUAWEI TECH CO LTD

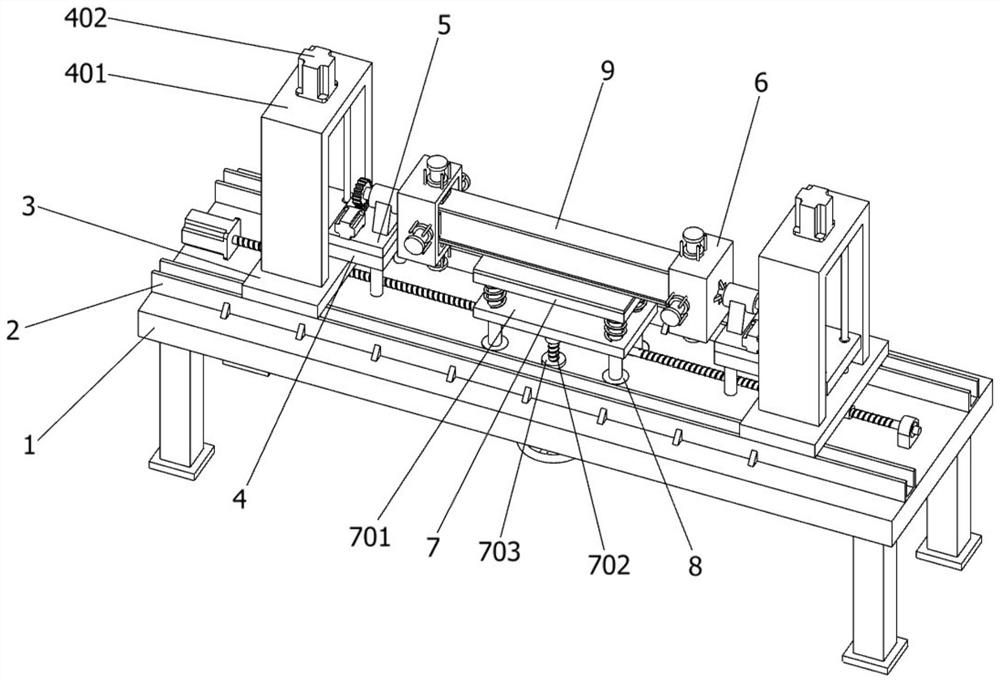

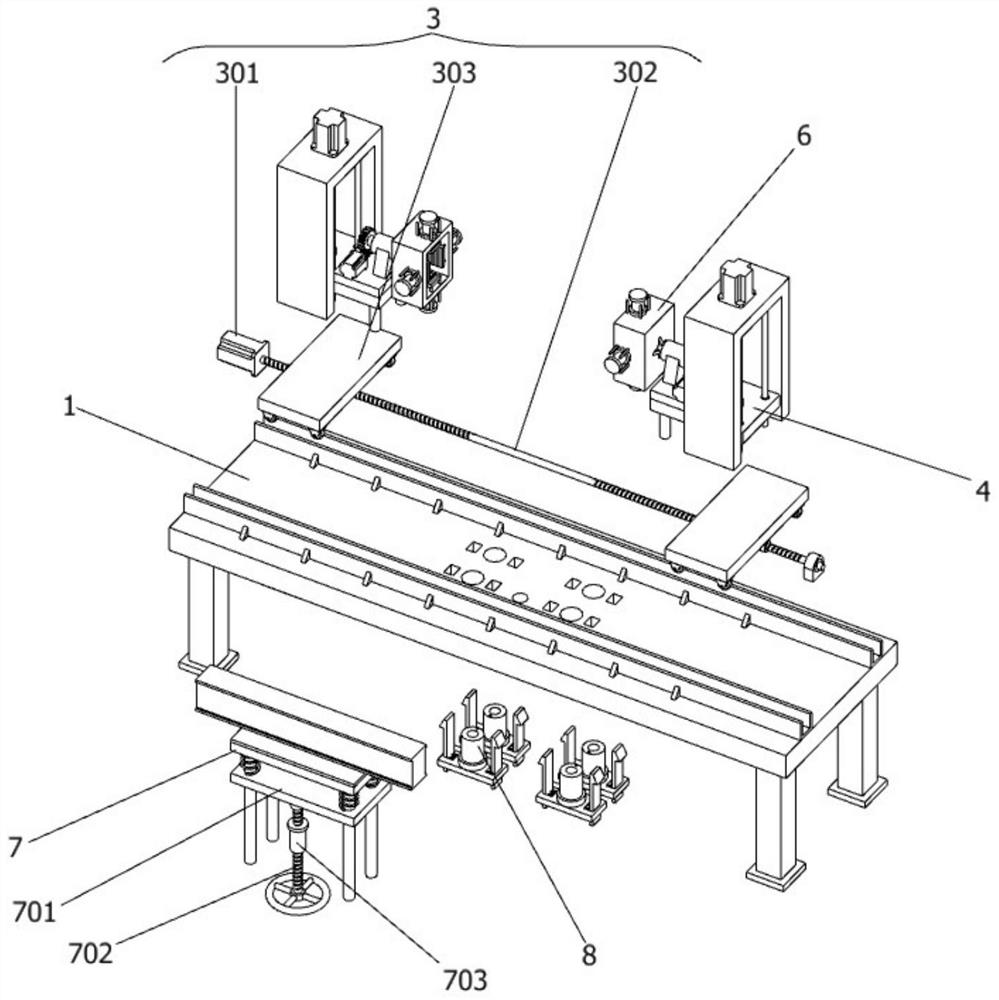

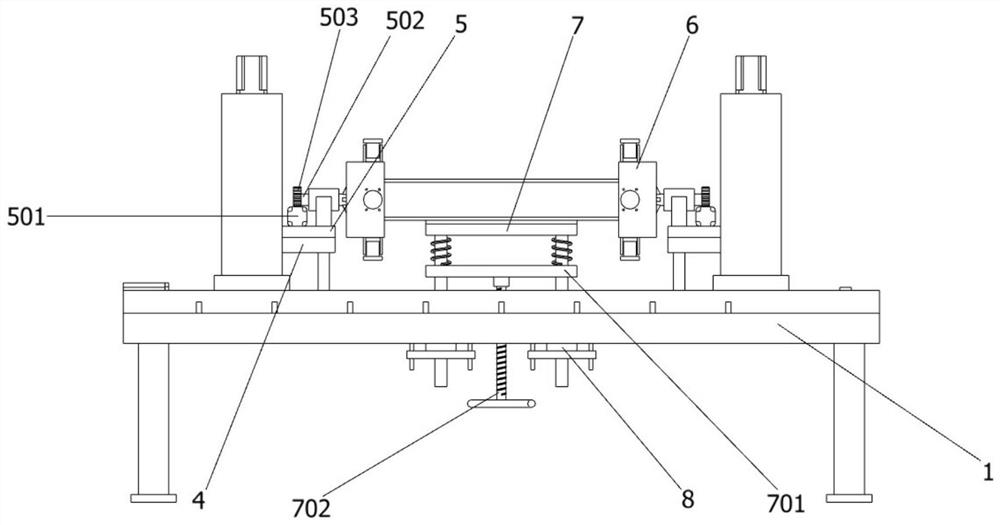

Mechanical arm overturning and clamping mechanism of construction machinery

InactiveCN112589826AImprove practicalityGood stabilityGripping headsArmsElectric machineryClassical mechanics

The invention provides a mechanical arm overturning and clamping mechanism of construction machinery, and belongs to the technical field of machining equipment. The problem that due to the lack of aneffective distance adjusting mechanism between two lifting mechanisms in the clamping mechanism, two rotary clamping mechanisms cannot be flexibly adjusted according to mechanical arms with differentlengths, and then the practicability of the clamping mechanism is reduced needs to be solved, so that the mechanical arm overturning and clamping mechanism comprises a rack, wherein two left square bracket-shaped sliding rails are arranged on the upper end face of the rack in a front-back symmetrical mode, and a distance adjusting mechanism is arranged on the upper portion of the rack. When the distance between the two lifting mechanisms is adjusted, a rotating shaft of an adjustment motor drives a distance adjusting screw rod to rotate, so that two moving plates drive the two lifting mechanisms, two angle adjusting mechanisms and the two rotary clamping mechanisms to move close to or away from each other under the action of two left-hand threads, then the two rotary clamping mechanisms can be flexibly adjusted according to the mechanical arms with different lengths, and the practicability of the clamping mechanism is improved.

Owner:温州简杰机械科技有限公司

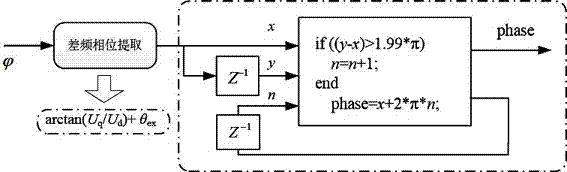

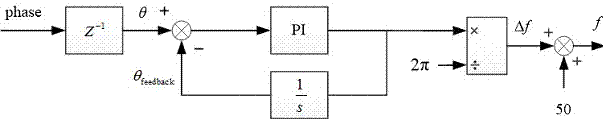

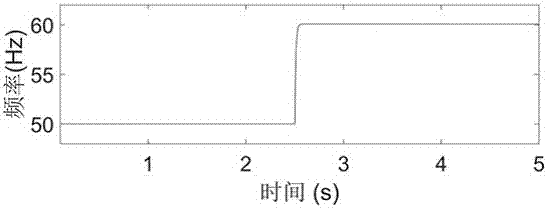

High-accuracy and anti-noise interference power grid frequency quick detection method

InactiveCN107271772AAccurate acquisitionAvoid differential operationsFrequency to phase shift conversionInterference resistanceClosed loop

The invention discloses a high-precision and anti-noise interference power grid frequency quick detection method, which comprises a power grid synchronous phase quick open loop detection link, a difference frequency phase calculation link and a frequency closed loop detection link. According to detected power grid voltage signals, through the power grid synchronous phase quick open loop detection link, the synchronous phase of the power grid can be acquired in real time, the difference frequency phase in the power grid synchronous phase is extracted through the difference frequency phase calculation link, the difference frequency phase information is inputted to the frequency closed loop detection link, and the real-time frequency of the power grid can be acquired. The power grid real-time frequency detection ability can be effectively improved, the measurement precision is high, the response speed is quick, the anti-interference performance is good, the stability problem of closed loop phase measuring and frequency measuring method in a weak power grid environment can be solved, and the application value is good.

Owner:NANJING INST OF TECH +1

Power distributing reactive optimizing compensation system based on GPRS and control method thereof

InactiveCN101335456BLarge capacityLow costReactive power adjustment/elimination/compensationReactive power compensationCapacitancePower compensation

The invention discloses a reactive power optimum compensation system and a control method thereof of a GPRS-based distribution network. The compensation system of the invention comprises a combination control system and an intelligent upper computer (industrial computer) with collaborative optimization control, wherein, the combination control system coordinately controls TSC and DSTATCOM on the same compensation node by a hybrid dynamic control method, and can also realize the data remote-transmission of the system parameters of the node to the intelligent upper computer with collaborative optimization control by a GPRS wireless communication network; the intelligent upper computer with collaborative optimization control searches the optimum compensation node and the compensation capacity by utilizing a multi-machine collaborative reactive power compensation method and also sends an optimum control command to a combination compensation system which then realizes the local large-capacity and continuous reactive power compensation by classified TSC capacitance switching and continuous DSTATCOM compensation. The reactive power optimum compensation system of the invention effectivelysolves the defects of poor capacity of resisting disturbance and difficult networking, etc. of the existing reactive power compensation system, and also reduces the operation cost.

Owner:HUNAN UNIV

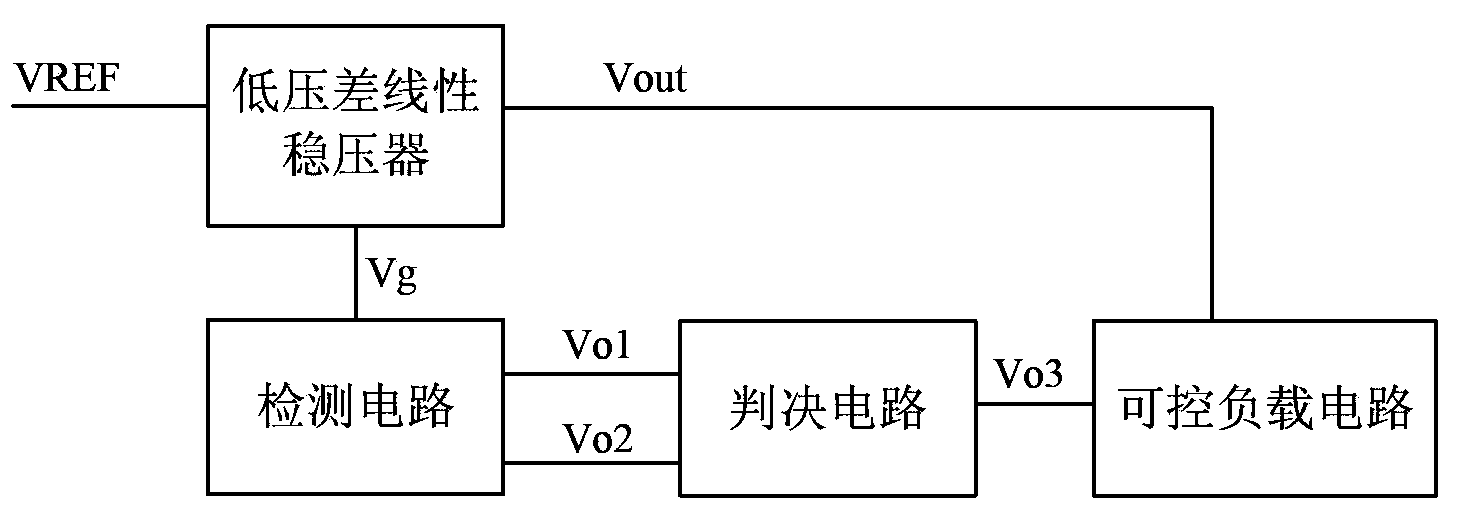

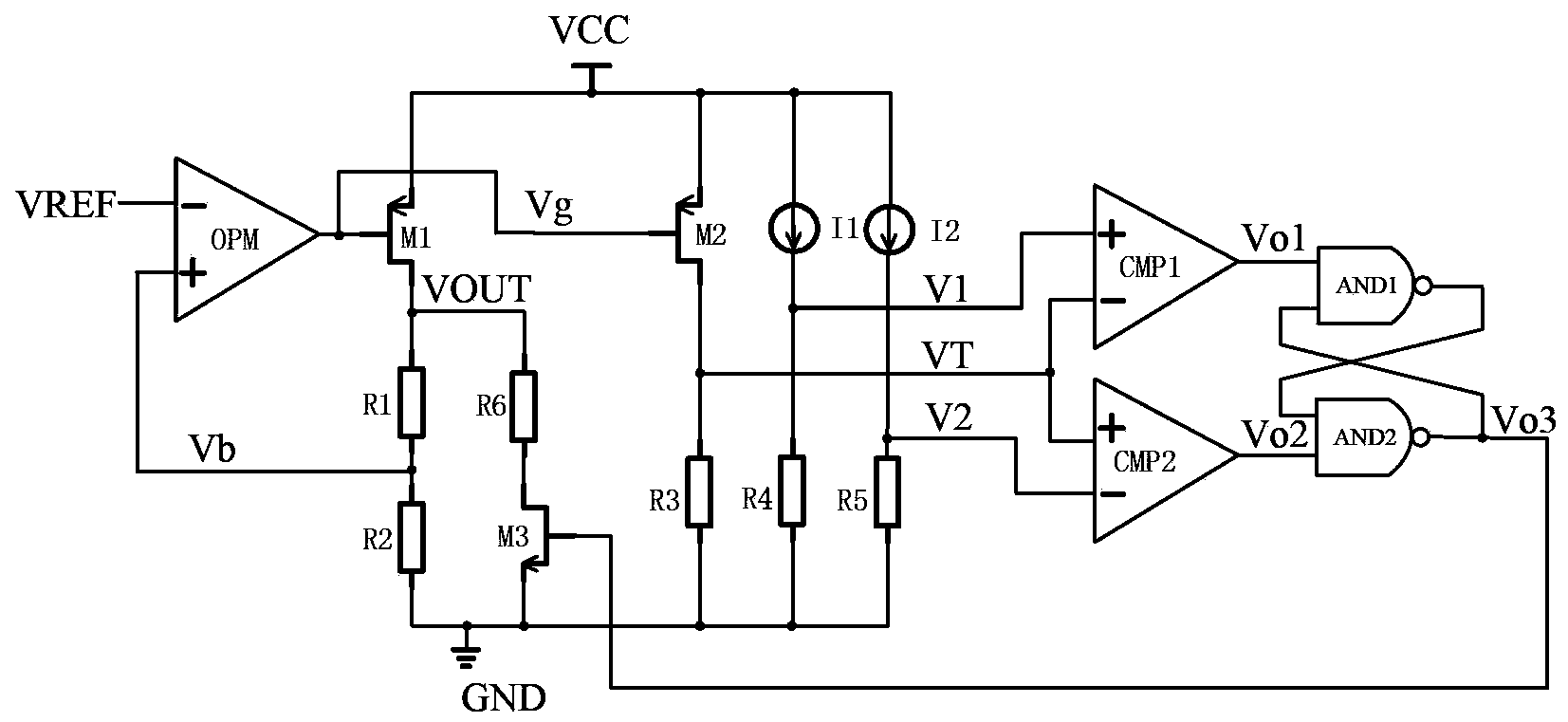

System for dynamically compensating phase margin of low dropout linear regulator

ActiveCN103383582APhase margin changesLoad changeElectric variable regulationDecision circuitLinear regulator

A system for dynamically compensating phase margin of a low dropout linear regulator comprises a low dropout linear regulator, a detection circuit, a decision circuit, a load controllable circuit, a reference voltage input end and a voltage output end, wherein the low dropout linear regulator amplifies input reference voltage to a certain scale, and outputs the amplified voltage to the voltage output end; the detection circuit detects the voltage at the voltage output end as per a set standard, and outputs a detection result to the decision circuit; the decision circuit decides the detection result as per a certain regulation, and outputs a decision result to the load controllable circuit; the load controllable circuit performs corresponding load change to the decision result, so as to change the phase margin of the low dropout linear regulator. The system can dynamically detect the phase margin of the low dropout linear regulator, and performs real-time compensation, so as to avoid the stability problem in the low dropout linear regulator during dynamic response.

Owner:CHENGDU ANALOG CIRCUIT TECH INC

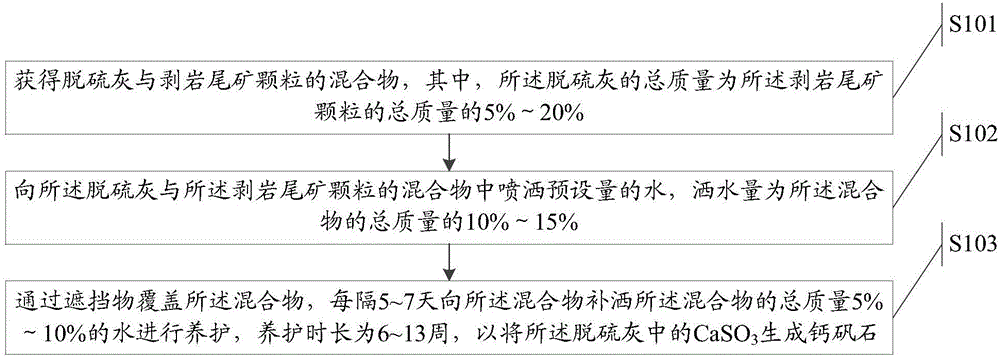

Method for stabilizing CaSO3 in desulfurized fly ash

ActiveCN106064172AAddress volume stability issuesImprove oxidation efficiencyTransportation and packagingSolid waste disposalPrillResource utilization

The invention relates to the field of solid waste resource utilization, discloses a method for stabilizing CaSO3 in desulfurized fly ash, and aims at solving the technical problem that the utilization of the CaSO3 in the desulfurized fly ash is relatively high in treatment cost and bad in application effect in the prior art. The method comprises the following steps: firstly obtaining a mixture of the sulfurized fly ash and stripping rock tailings particles, wherein the total mass of the desulfurized fly ash is 5-20% of the total mass of the stripping rock tailings particles; spraying a preset amount of water in the mixture of the sulfurized fly ash and the stripping rock tailings particles, wherein the water yield is 10-15% of the total mass of the mixture; and finally covering the mixture through a screen, and maintaining the mixture through spraying water which is 5-10% of the total mass of the mixture to the mixture every 5-7 days, wherein the maintenance time length is 6-13 weeks so that the CaSO3 in the desulfurized fly ash generates ettringite. According to the method disclosed in the invention, the technical effect of reducing the treatment cost while the desulfurized fly ash is effectively utilized is achieved.

Owner:武汉钢铁有限公司

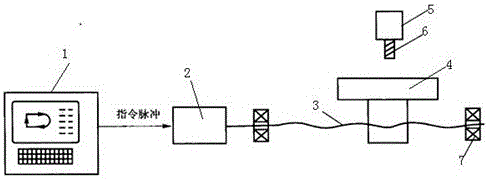

Control system of numerical control machine tool

InactiveCN105058160ALow priceAccurate transmission errorAutomatic control devicesFeeding apparatusNumerical controlDistributor

The invention relates to a control system of a numerical control machine tool. The control system comprises an MCU controller, a stepping motor, a lead screw, a machine tool working table, a main shaft, a tool and bearings. An instruction pulse output by the MCU controller is connected with the stepping motor. A drive shaft of the stepping motor is connected with and provided with the lead screw. The two ends of the lead screw are connected with and provided with the bearings. The lead screw and the machine tool working table are matched and connected with each other. A main shaft box is arranged above the machine tool working table. A feeding instruction signal output by the MCU controller controls and drives the motor through a pulse distributor. In addition, a speed detector and a position detector are arranged, the position detector is connected with a position comparator through a signal line, and the speed detector is connected with the speed controller through a signal line. Transmission error in a whole mechanical transmission chain from the motor to the machine tool working table is eliminated through feedback, and therefore the accurate position of the machine tool working table is obtained; the control system is convenient to control, simple in structure and low in price.

Owner:WUHU RISHENG HEAVY DUTY MACHINE TOOLS

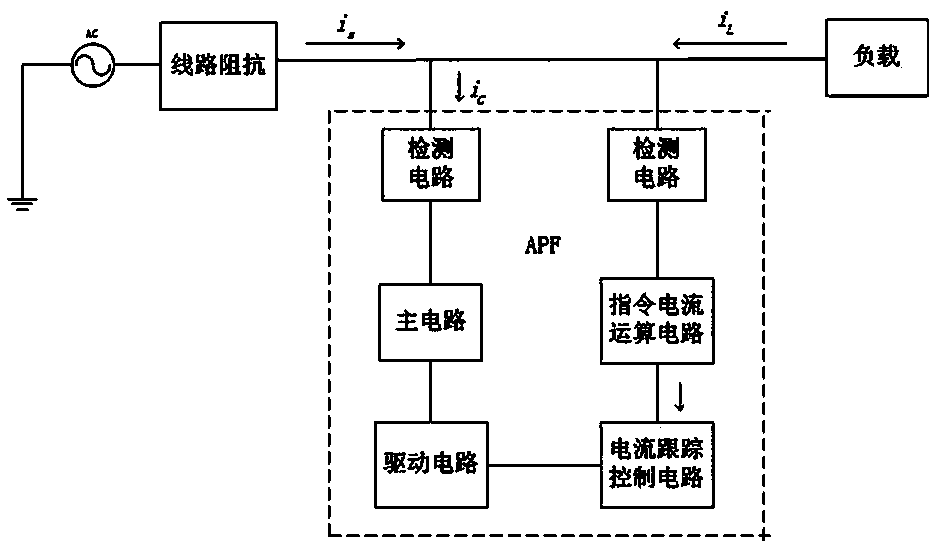

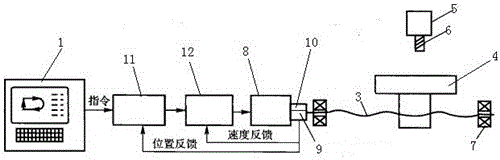

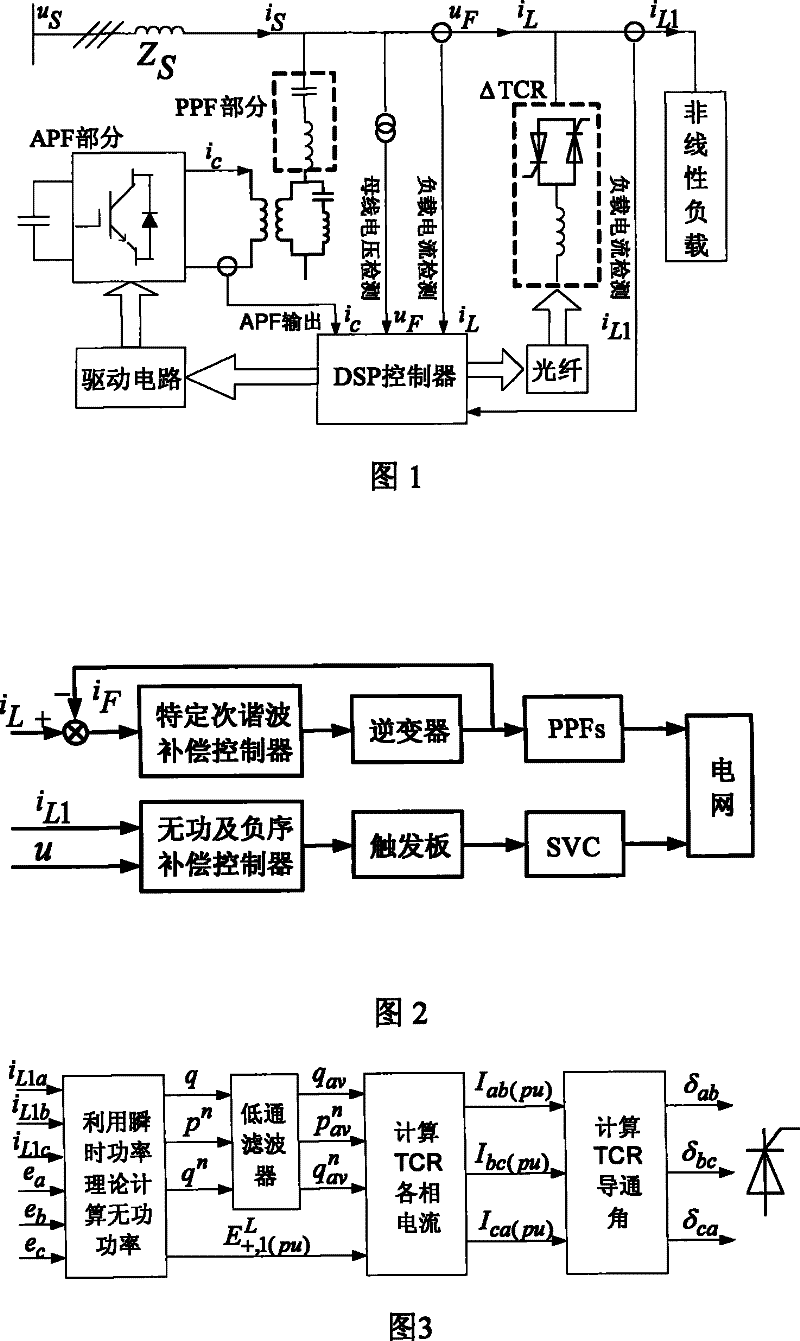

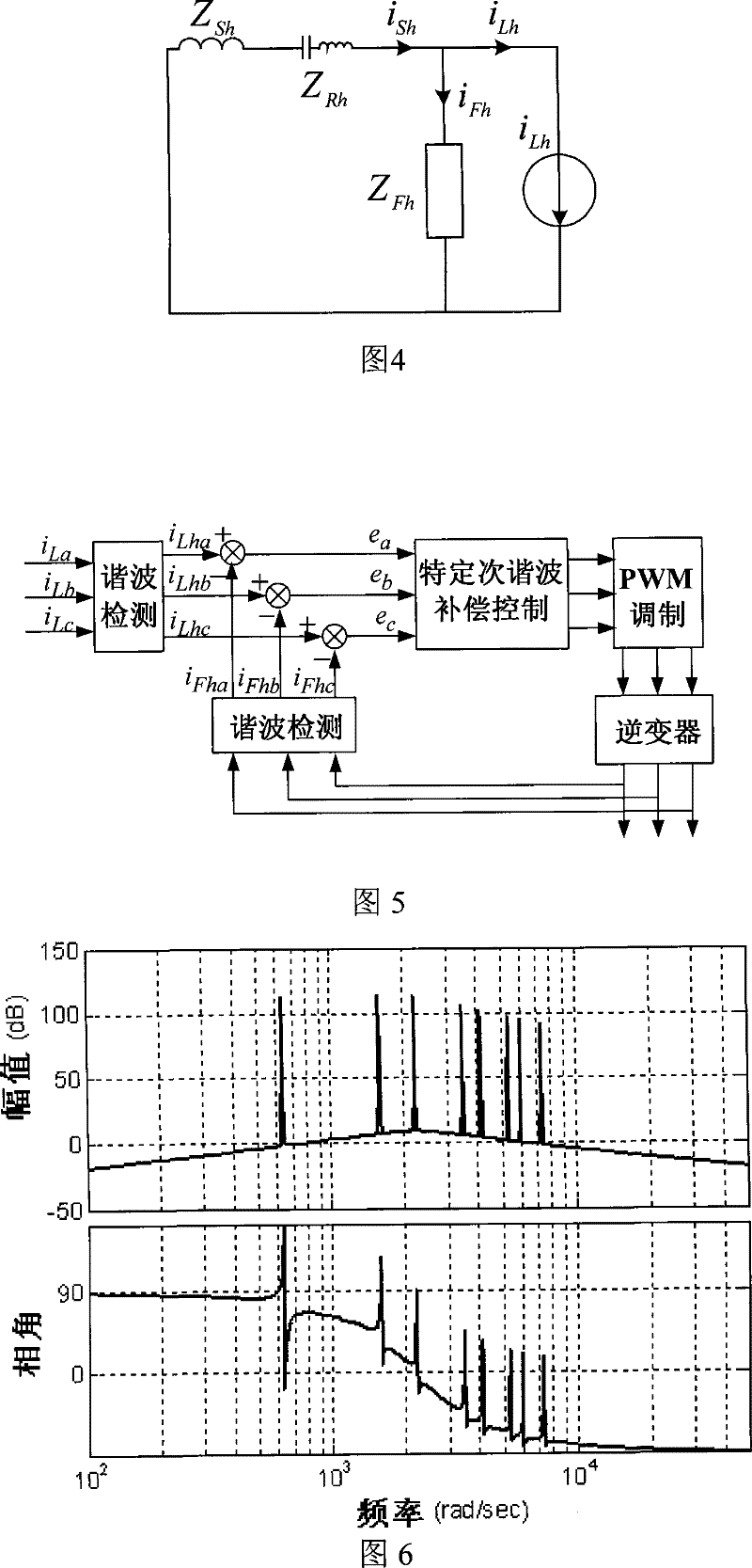

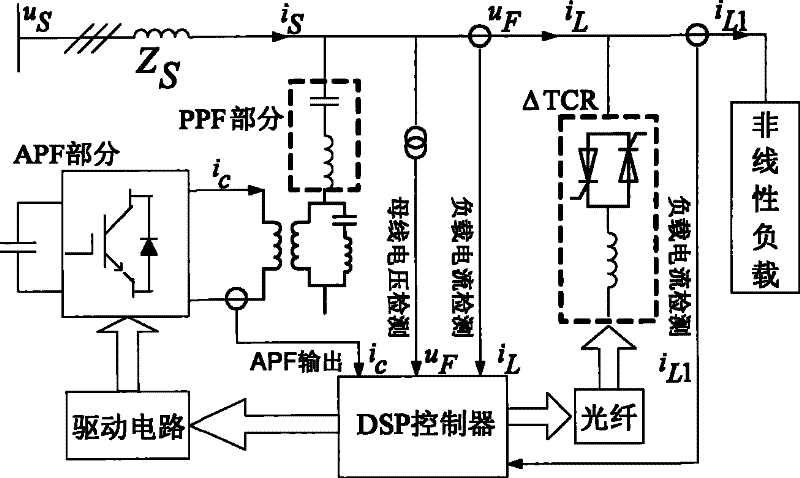

Static reactive compensator and active power filter combined operation system and control method thereof

InactiveCN101183791BSuppression of series and parallel resonanceEasy to filterFlexible AC transmissionActive power filteringResonanceHarmonic

The invention discloses a joint operating system of the static var compensator and active power filter and the control method, which is characterized in that an active power filter and a control device are added in the static var compensator. The control method of balance compensation of three-phase unbalanced loads is used to realize the compensation of load negative sequence current and the technology of specific subharmonic compensation is used to realize the decoupling control of SVC and APF, so as to guarantee the safe and stable operation of the joint operating system. The invention notonly has the basic functions of the SVC, but also improves the filtering performance of the passive filter through APF, suppresses possible resonance phenomena between the passive component and the power grid equivalent impedance, and can realize dynamic management on subharmonic waves.

Owner:HUNAN UNIV

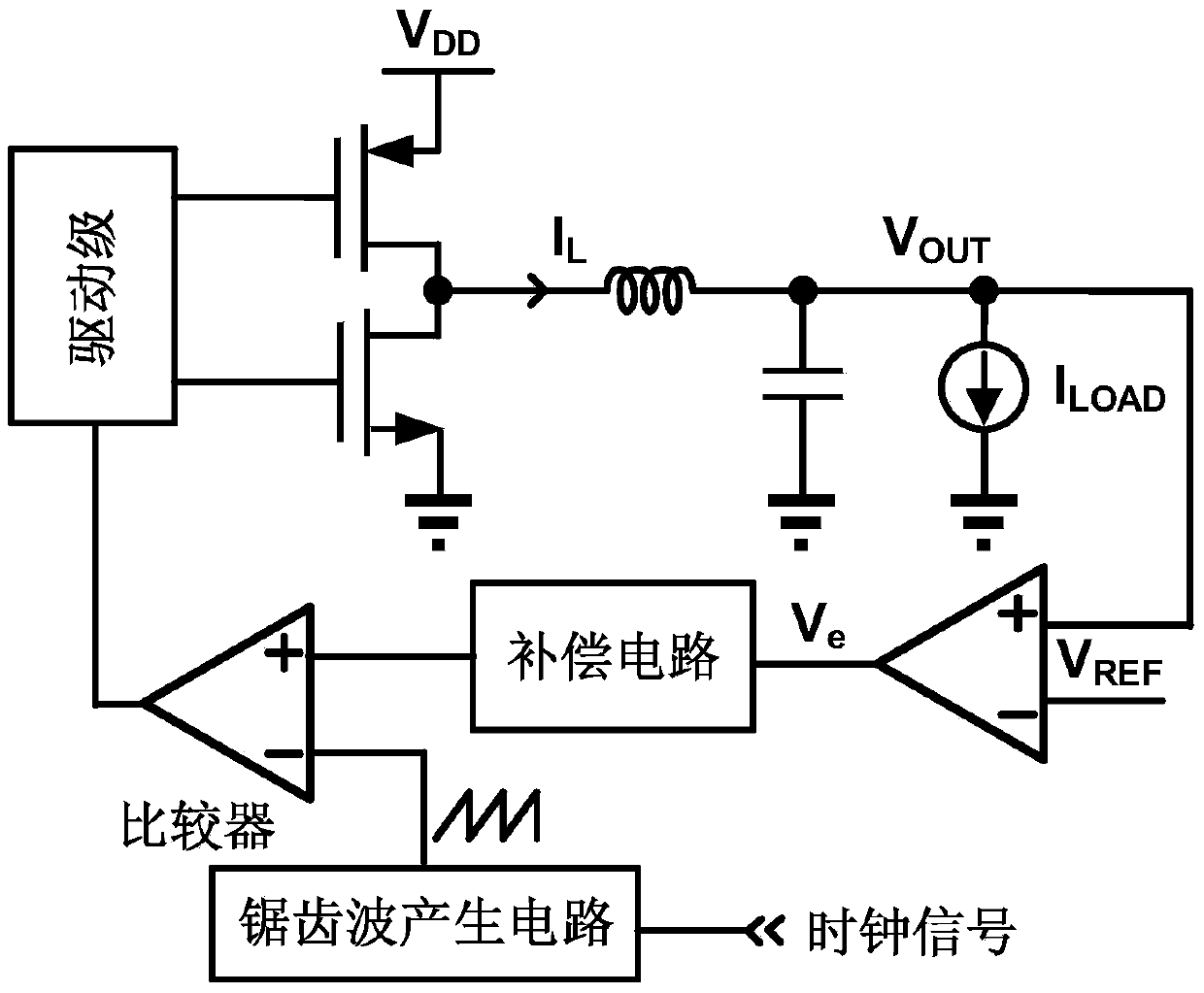

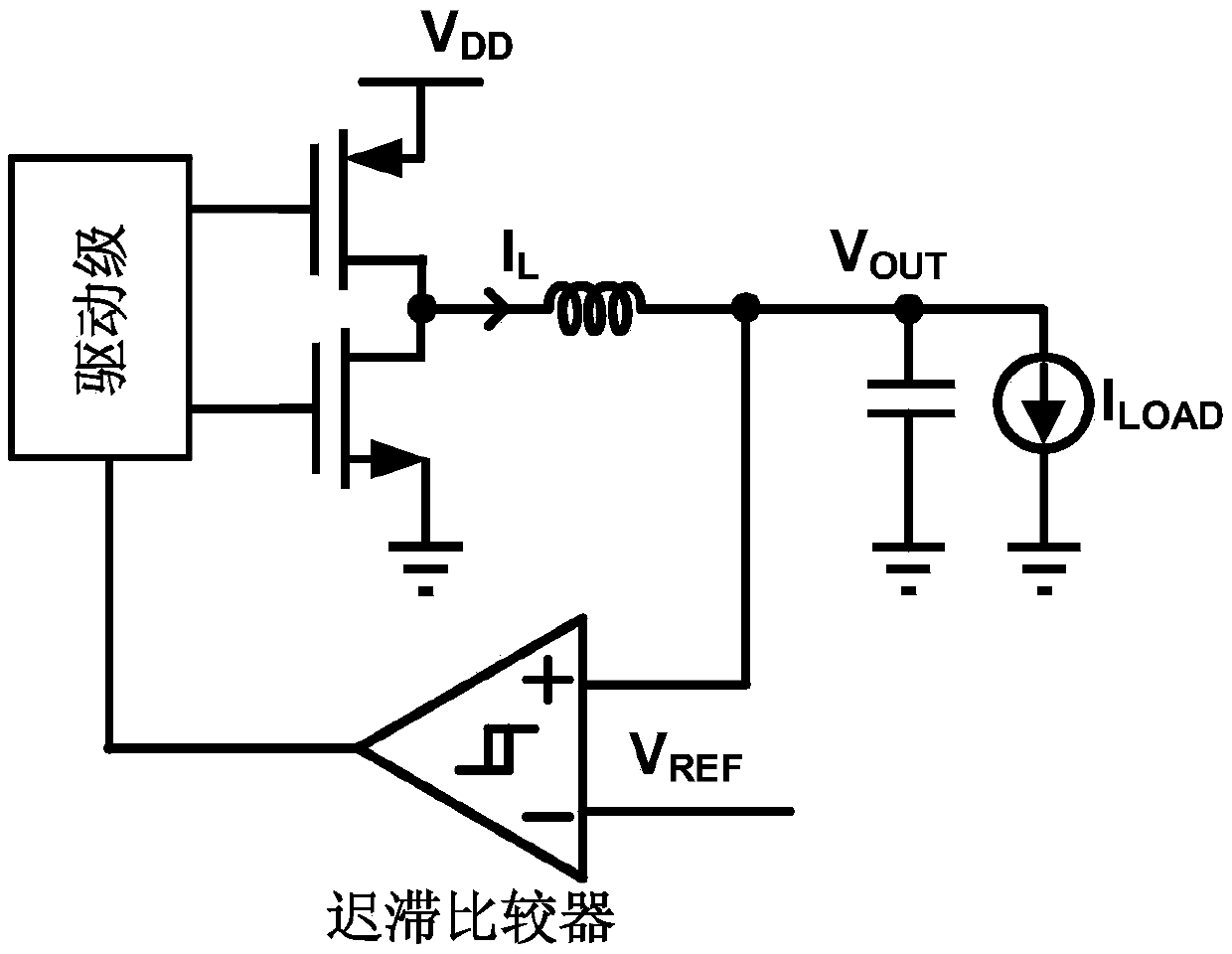

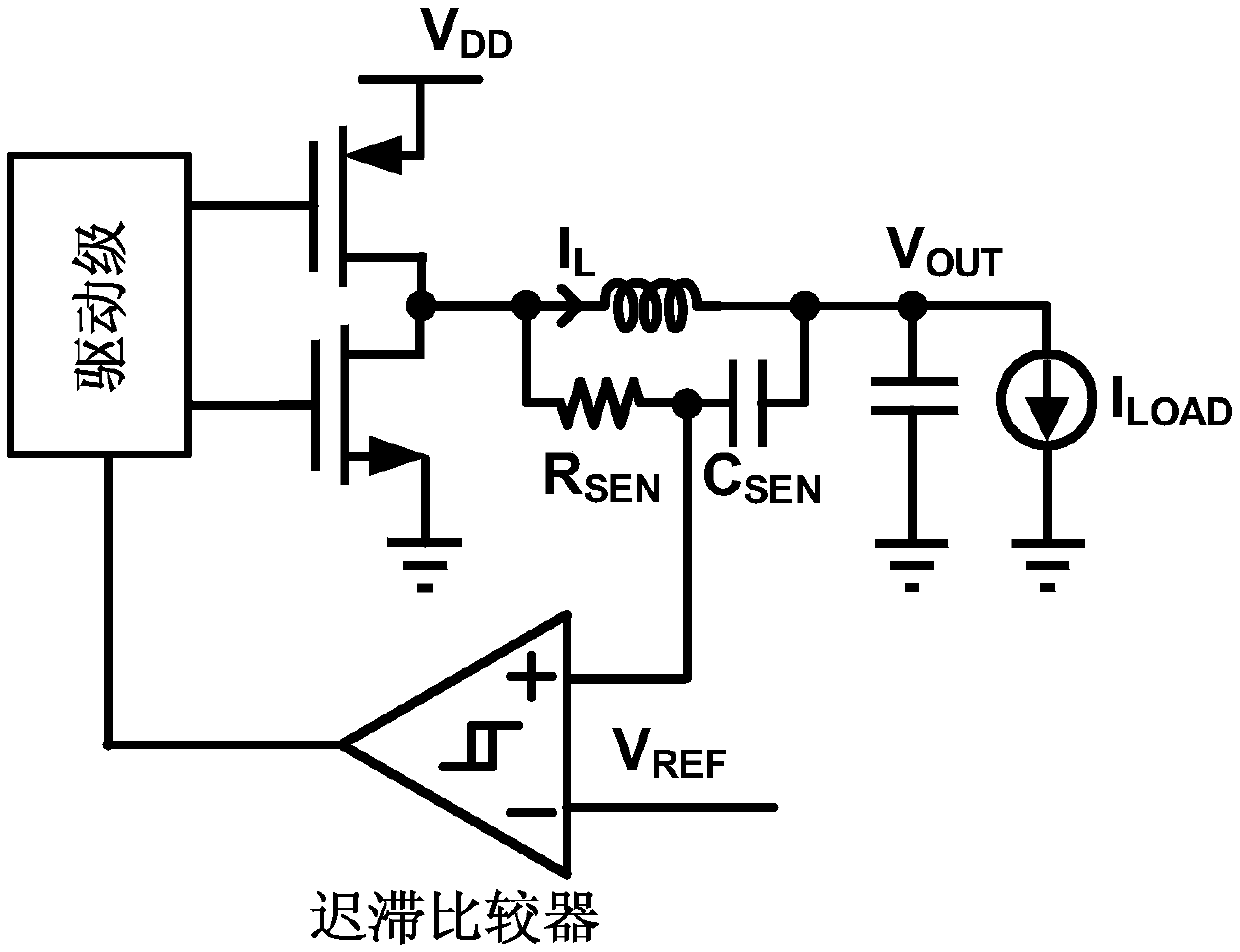

DC-DC converter based on ring oscillator

InactiveCN105515386ANo stability issuesReduce power consumptionDc-dc conversionElectric variable regulationDc dc converterControl circuit

The invention relates to a DC-DC converter based on a ring oscillator, and the theory of the ring oscillator is used for realizing the control of the DC-DC converter. The free oscillation of a feedback control loop of the DC-DC converter is utilized by the DC-DC converter for generating a signal for controlling on and off of a switch tube without adding a pulse signal; and the voltage is stably outputted through a comparator. The power consumption generated by a control circuit of the DC-DC converter is low, and the high conversion efficiency can be realized in a wide load range; the control circuit of the DC-DC converter is simple, has no stability problem, and does not need a compensating circuit; the chip area occupied by the DC-DC converter is smaller than the prior art to save cost; and the DC-DC converter has a faster response speed and a smaller ripple than the prior art.

Owner:PEKING UNIV

Positive electorde for secondary battery and lithium secondary battery including the same

ActiveCN110114914AImprove stabilityAct as an insulating layerPositive electrodesElectrode collector coatingElectrical batteryPhysical chemistry

The present invention relates to an anode for a secondary battery for improving stability during overcharging and a lithium secondary battery including the same. Specifically, the anode is an anode including an anode active material layer formed on an anode current collector. The anode active material layer has a two-layer structure including a first anode active material layer formed on the anodecurrent collector and a second anode material layer formed on the first anode active material layer. The first anode active material layer includes a first anode active material, a conductive material, and a volumetric expansion resin in which volume expansion occurs at a high temperature upon overcharging, and the second anode active material layer includes a second anode active material.

Owner:LG ENERGY SOLUTION LTD

Speed regulating fan system with fault-tolerant capacity

ActiveCN100440718CReduce power consumptionReduce noiseElectric motor controlField or armature current controlElectricityControl signal

This invention relates to a fan regulation system with an error-tolerance ability including an input voltage testing circuit, a PWM circuit, a switch supply circuit and a fan set, in which, the control signal of rotation speed of the system and tested voltage signal control the output of the PWM waveforms, control the switch devices of a switch supply circuit and output a suitable voltage to the fan set, when the fan is tested to be faulty, the duty ratio of the PWm waveform can be adjusted.

Owner:ZTE CORP

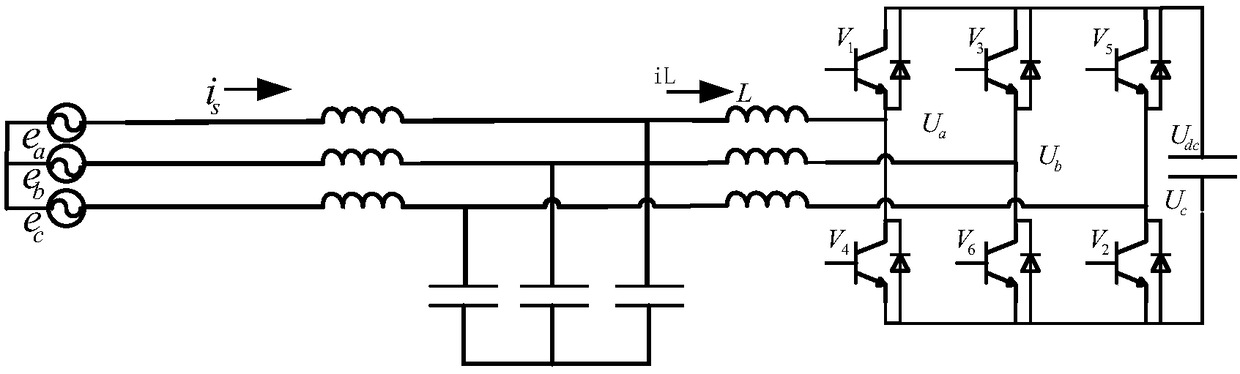

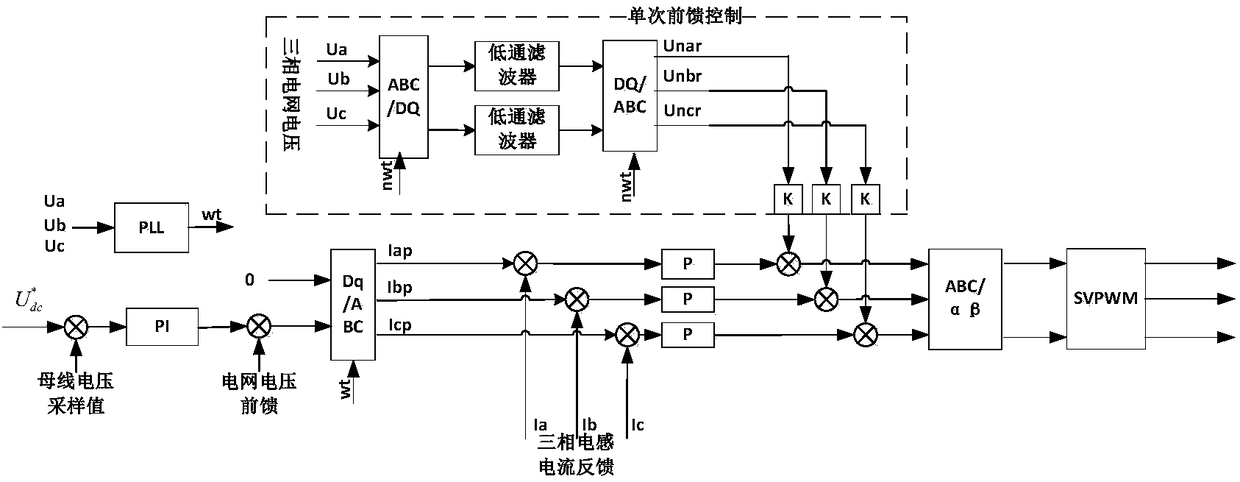

Control method for three-phase PWM rectifier for grid voltage waveform distortion

ActiveCN108134391ASuppress waveform distortionEasy to implementAc-dc conversionHarmonic reduction arrangementThree phase pwm rectifierHarmonic

The invention discloses a control method for a three-phase PWM rectifier for grid voltage waveform distortion. The method is characterized in that feedforward control of grid voltage harmonic components is carried out. The method specifically comprises the following steps of detecting an instantaneous value of three-phase grid voltage; extracting a needed single harmonic by utilizing an instantaneous power conversion algorithm in order to obtain an alternating current instantaneous value of each harmonic in the grid voltage, wherein the harmonic can be flexibly selected according to the fieldcondition; and multiplying the alternating current instantaneous value of each harmonic by an amplitude correction coefficient, feeding forwarding to a control loop, and carrying out feedforward control. The method has the advantages that the implementation is simple, a stability problem is avoided, and the frequency deviation is not affected, and meanwhile, the maximum grid voltage waveform distortion can be inhibited, and compared with other control methods, the method has considerable application prospect.

Owner:西安翌飞核能装备股份有限公司

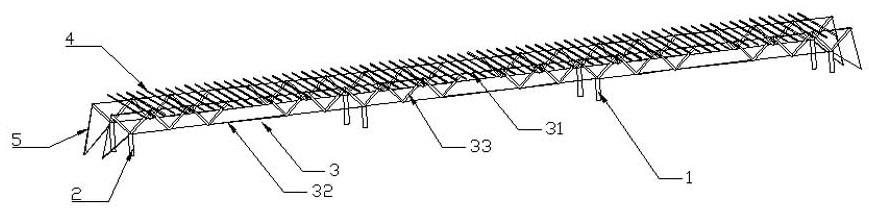

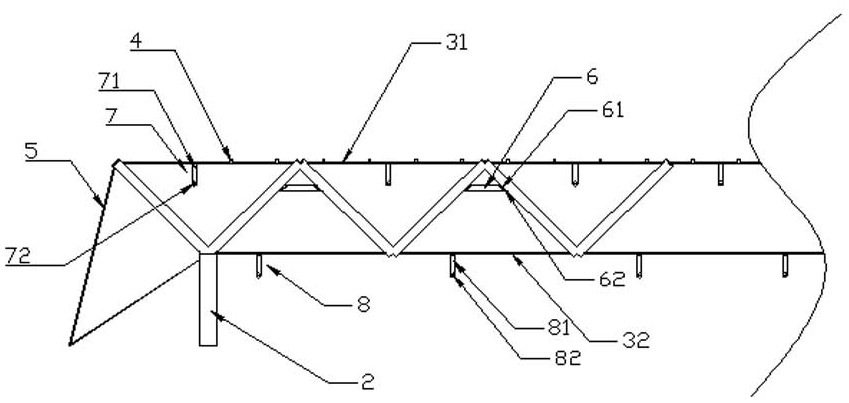

Photovoltaic cable truss support

PendingCN114777342AThe number of piles is smallLow number of pilesPhotovoltaic supportsSolar heating energyStructural engineeringMechanical engineering

The invention belongs to the technical field of photovoltaic supports, and particularly relates to a photovoltaic cable truss support which comprises a plurality of middle stand columns arranged in rows and end stand columns arranged at the two ends of each row; a cable truss mechanism is erected on each row of end upright posts and middle upright posts; the cable truss mechanism comprises an upper chord cable, a lower chord cable and an inclined rod, and the inclined rod is arranged between the upper chord cable and the lower chord cable; the upper chord cable and the lower chord cable are flexible inhaul cables; a plurality of purlines are laid on the upper chord cables of every two rows of cable truss mechanisms; and the end upright post is provided with a cable-stayed part connected to an external fixed part. The photovoltaic cable truss bracket has the advantages of material saving, strong bearing capacity and strong deformation resistance, thereby achieving the effect of improving the stability of a photovoltaic module.

Owner:庞亮

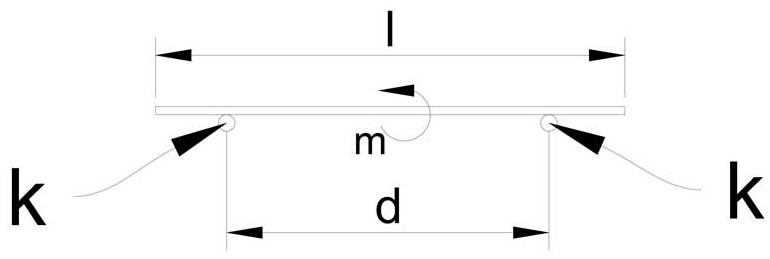

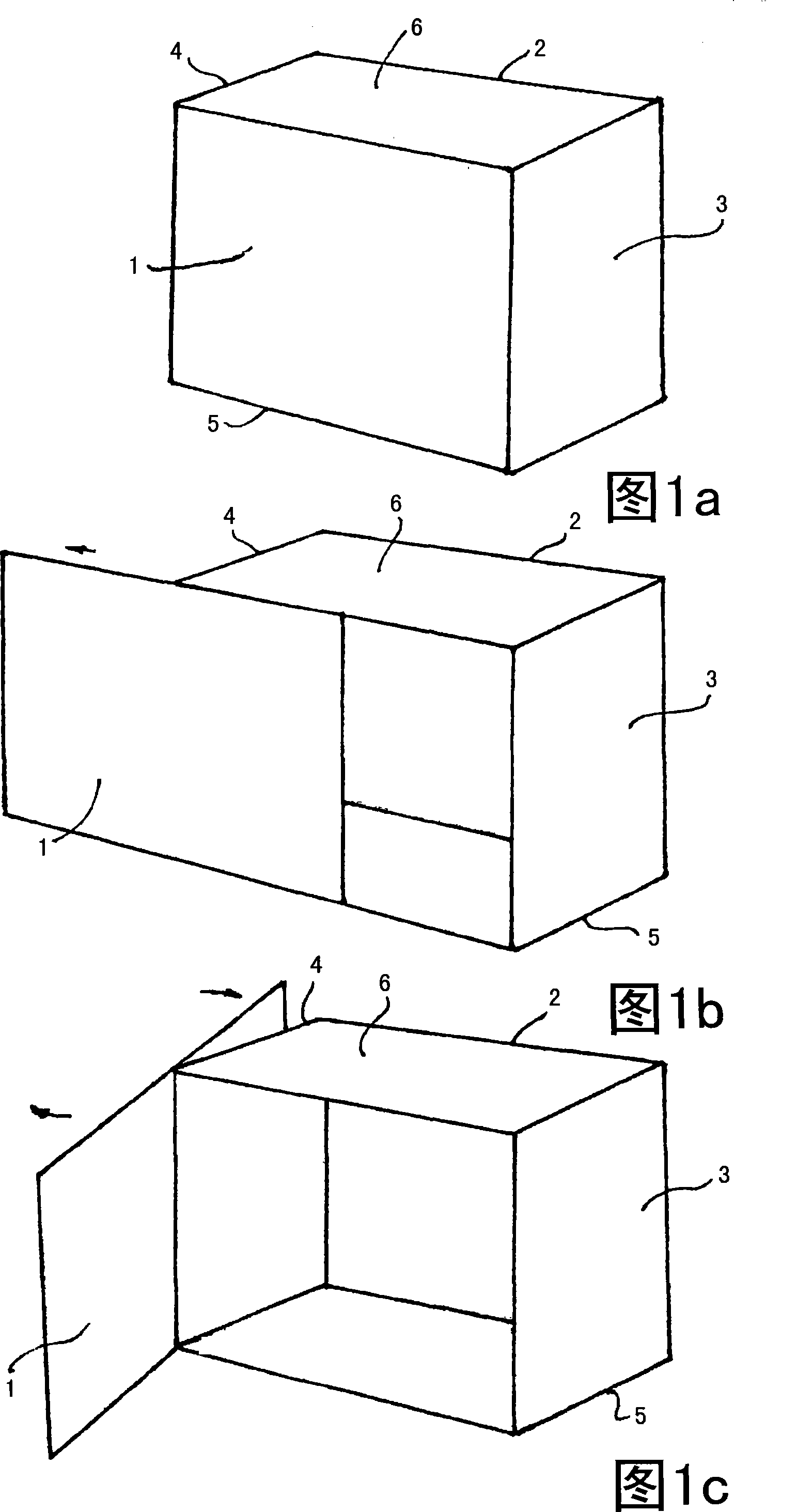

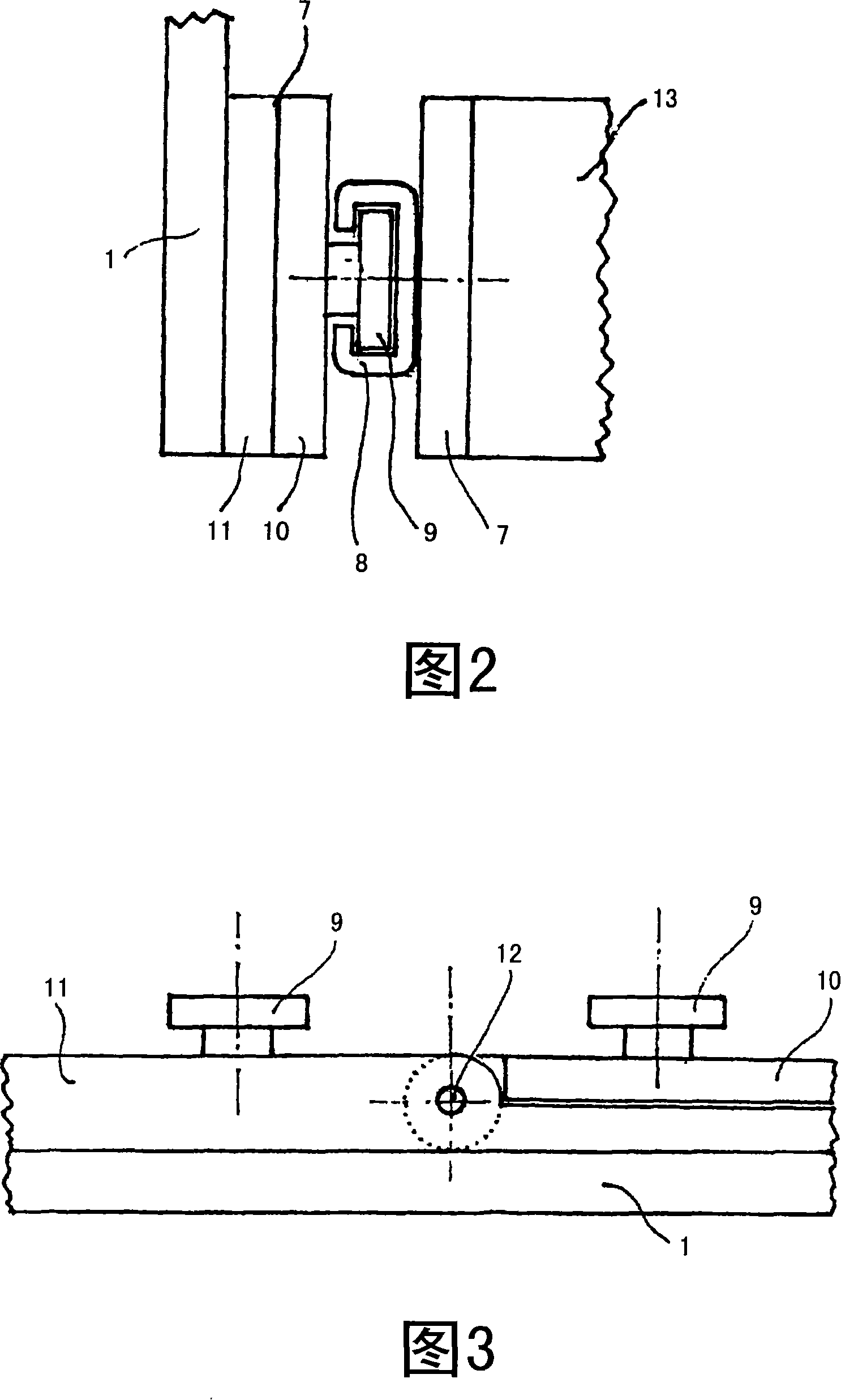

Glass cabinet for storage and/or display of objects

InactiveCN101166448BReduce layoutNo stability issuesShow cabinetsWing suspension devicesEngineeringDisplay cabinet

The display cabinet has a door (1) which is mounted on rollers (9). These slide in C-profile rails at the top and bottom and the door is fitted with hinges (12) which allow it to swivel so that it rests against the side of the cabinet when it reaches its end position.

Owner:GLASBAU HAHN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com