Method for stabilizing CaSO3 in desulfurized fly ash

A desulfurized ash and semi-dry technology, which is applied in the field of solid waste resource utilization, can solve the problems of poor application effect and high processing cost, and achieve the effects of scientific and reasonable technical effect, simple operation and strong practicability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

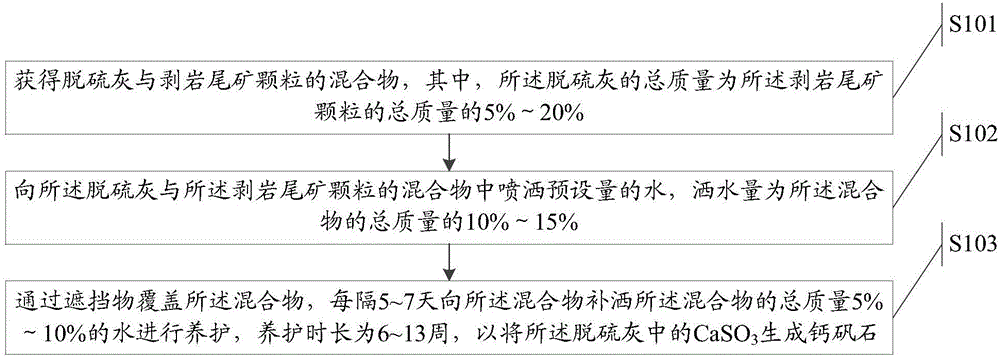

Method used

Image

Examples

Embodiment 1

[0048] (1) Mix the desulfurization ash and the rock-stripping tailings particles evenly, wherein the total mass of the desulfurization ash is 10% of the total mass of the rock-stripping tailings particles, take a certain amount of samples, place them in an oven at 105°C and heat them to constant weight, And the CaSO in the mixture was determined by iodometric method 3 The content accounts for 2.8% of the total mass of the mixture;

[0049] (2) Spray water accounting for about 10% of the total mass of the mixture in the mixture;

[0050] (3) Use cotton cloth to cover the mixture, and sprinkle about 5% water of the total mass of the mixture to the mixture every 7 days for maintenance, and continue to maintain for 8 weeks;

[0051] (4) After 7 days from the last replenishment of water, remove the cotton cloth, let the mixture dry naturally for 3 days, take a certain amount of samples, place them in an oven at 105°C and heat them to constant weight, and measure the CaSO in the mi...

Embodiment 2

[0053] (1) Mix the desulfurization ash and the rock-stripping tailings particles evenly, wherein the total mass of the desulfurization ash is 15% of the total mass of the rock-stripping tailings particles, take a certain amount of samples, place them in an oven at 105°C and heat them to constant weight, And the CaSO in the mixture was determined by iodometric method 3 The content accounts for 4.8% of the total mass of the mixture;

[0054] (2) Spray water accounting for about 10% of the total mass of the mixture in the mixture;

[0055](3) Use cotton cloth to cover the mixture, and sprinkle water of about 7% of the total mass of the mixture to the mixture every 7 days for maintenance, and maintain for 9 weeks;

[0056] (4) After 7 days from the last replenishment of water, remove the cotton cloth, let the mixture dry naturally for 3 days, take a certain amount of samples, place them in an oven at 105°C and heat them to constant weight, and measure the CaSO in the mixture by i...

Embodiment 3

[0058] (1) Mix the desulfurization ash and the rock-stripping tailings particles evenly, wherein the total mass of the desulfurization ash is 15% of the total mass of the rock-stripping tailings particles, take a certain amount of samples, place them in an oven at 105°C and heat them to constant weight, And the CaSO in the mixture was determined by iodometric method 3 The content accounts for 4.1% of the total mass of the mixture;

[0059] (2) Spray water accounting for about 12% of the total mass of the mixture in the mixture;

[0060] (3) Use cotton cloth to cover the mixture, and sprinkle water accounting for about 7% of the total mass of the mixture to the mixture every 7 days for maintenance, and continue to maintain for 6 weeks;

[0061] (4) After 7 days from the last replenishment of water, remove the cotton cloth, let the mixture dry naturally for 3 days, take a certain amount of samples, place them in an oven at 105°C and heat them to constant weight, and measure the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com