A carbon-bonded magnesium-silicon-calcium gunning material for steelmaking electric furnace maintenance

A technology of gunning material and magnesium silicon, which is applied in the field of refractory materials for steelmaking electric furnace maintenance, can solve problems such as unsatisfactory service life, general use effect, and reduced corrosion resistance, so as to reduce peeling, reduce quantity, and improve steel quality. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

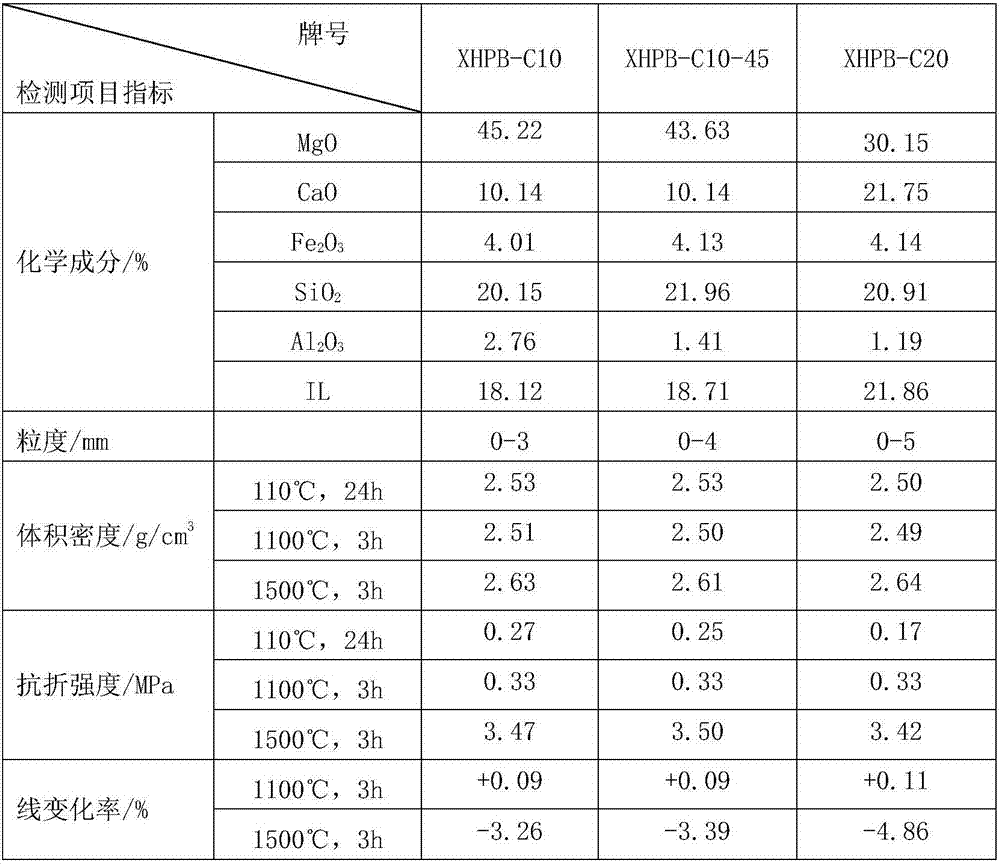

Embodiment 1

[0038] Preparation of carbon-bonded magnesium-silicon-calcium gunning material XHPB-C10 for steelmaking electric furnace maintenance:

[0039] 1) Raw material crushing, screening and fine grinding: the limestone is crushed in a crusher to make particles with a particle size of 1mm≤particle size90% magnesia in a crusher or Raymond machine to make particles of 0.074mm≤particle size<1mm and particles with a particle size<0.074 mm particles.

[0040] 2) Proportion mixing and packaging: Add 10 parts of limestone granules with 1mm≤particle size90% magnesia 0.074mm≤particle size<1mm, and 22.5 parts of granular materials with a particle size of<0.074mm In addition, 9.2 parts of binder are added; after mixing evenly, it is completed through steps such as detection and packaging.

[0041] In this example, the binder is composed of the following components in parts by weight: 5 parts of asphalt with a particle size of ≤1 mm, 2.5 parts of slaked lime with a particle size of ≤400 mesh, 1....

Embodiment 2

[0043] Preparation of carbon-bonded magnesium-silicon-calcium gunning material XHPB-C10-45 for steelmaking electric furnace maintenance:

[0044] 1) Raw material crushing, screening and fine grinding: the limestone is crushed in a crusher to make particles with a particle size of 1 mm ≤ particle size 85% magnesia in a crusher or Raymond machine to make particles greater than or equal to 0.074mm ≤ particle size < 1mm And particles with a particle size <0.074mm.

[0045] 2) Proportion mixing and packaging: add 10 parts of limestone granules with 1mm≤particle size85% magnesia, In addition, 9.2 parts of binding agent are added; after mixing evenly, it is completed through steps such as detection and packaging.

[0046]In this example, the binder is composed of the following components by weight: 5 parts of asphalt with a particle size of ≤1mm, 2.5 parts of slaked lime with a particle size of ≤400 mesh, 1.0 part of microsilica powder, 0.5 part of hydroxypropyl methylcellulose, so...

Embodiment 3

[0048] Preparation of carbon-bonded magnesium-silicon-calcium gunning material XHPB-C20 for steelmaking electric furnace maintenance:

[0049] 1) Raw material crushing, screening and fine grinding: the limestone is crushed in a crusher to make particles with a particle size of 1 mm ≤ particle size 90% magnesia in a crusher or a Raymond machine to make particles with a particle size of <0.074mm respectively.

[0050] 2) Proportion mixing and packaging: add 10 parts of limestone granules with 1mm≤particle size90% magnesia and smaller than 0.074mm, and 9.2 parts of a binder; The steps of detection and packaging are completed.

[0051] The binder in this example is composed of the following components in parts by weight: 5 parts of asphalt with a particle size of ≤1mm, 2.5 parts of slaked lime with a particle size of ≤400 mesh, 1.0 part of microsilica powder, 0.5 part of hydroxypropyl methylcellulose, lauryl sulfuric acid Sodium 0.2 parts.

[0052] The typical values of the ph...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com