Ultra-light cement-based composite foaming material and preparation method thereof

A composite foaming and cement-based technology, which is applied in the field of building insulation materials, can solve problems such as fire accidents, poisonous gas emission, and poor insulation effects in insulation projects, and solve the problem of slurry volume stability, reduce surfactant content, The effect of promoting overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

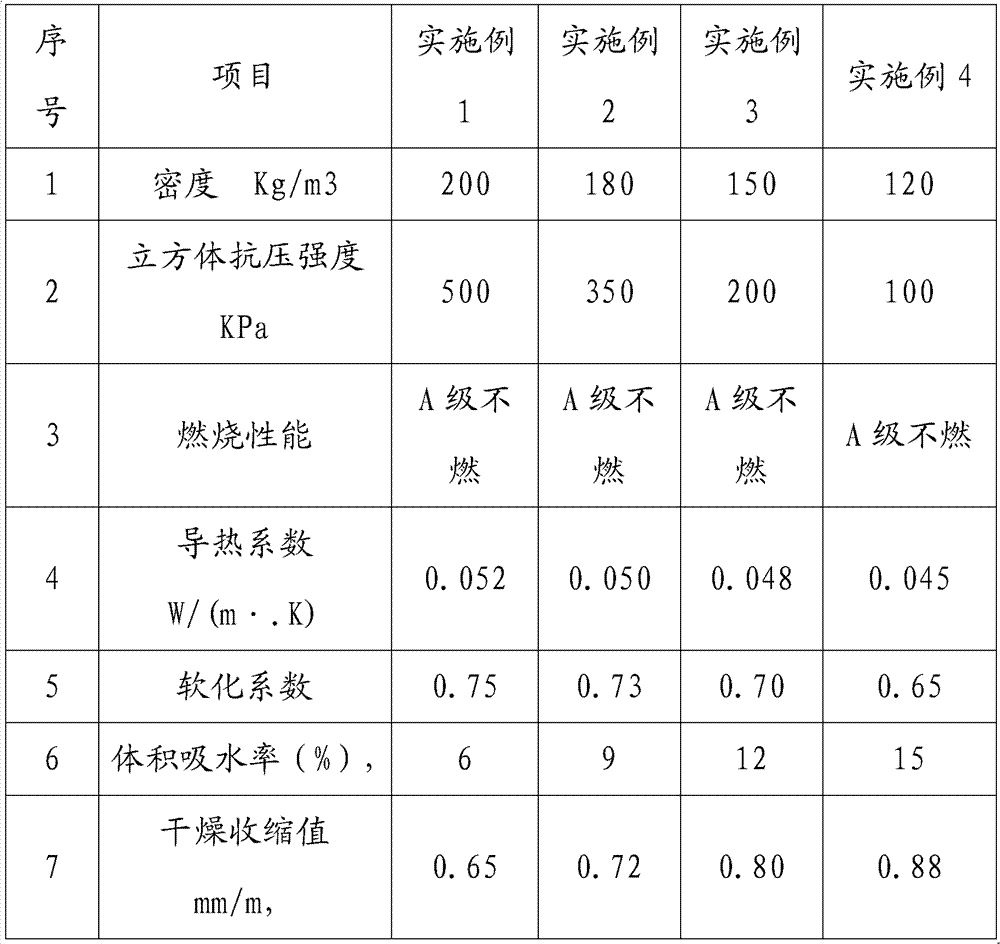

Embodiment 1

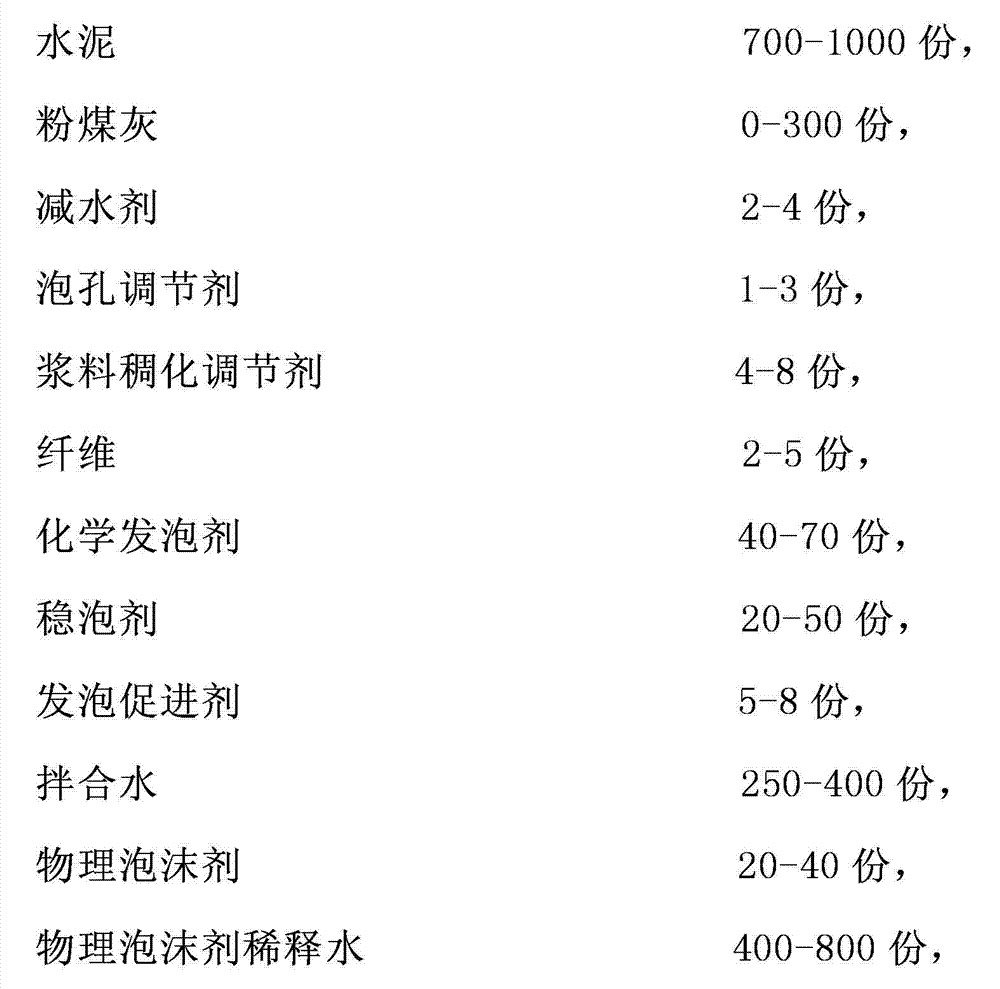

[0073] Take 700 parts of Portland cement, 300 parts of fly ash, 2 parts of water reducing agent, 3 parts of cell regulator, 8 parts of slurry thickening regulator, 5 parts of fiber, and 20 parts of foam stabilizer and mix them evenly with a mixer. Then add 400 parts of water and stir for 3 minutes to form a pure slurry.

[0074] At the same time, 420 parts of the physical foam agent dilution were taken and stirred for 5 minutes by a paddle mixer at a speed of 1000 rpm to obtain a water-film foam.

[0075] Add the obtained water-film foam to the above-mentioned clean slurry and stir for 1 minute to obtain a foam slurry, then add 40 parts of a chemical foaming agent and 5 parts of a foaming accelerator to the foam slurry and mix them, after stirring for 30 seconds, pour into the mold, the pouring height is one-fifth of the mold height. Before pouring, the mold should complete the process of brushing the release agent to ensure that the edges, corners, corrugations, partitions, ...

Embodiment 2

[0079] The preparation method and steps are the same as in Example 1. The amounts of different components added are 800 parts of sulphoaluminate cement, 200 parts of fly ash, 3 parts of water reducer, 2 parts of cell regulator, and the slurry is thick. 7 parts of chemical regulator, 4 parts of fiber, 30 parts of foam stabilizer, 350 parts of mixing water, 6 parts of foam accelerator, 50 parts of chemical foaming agent, 25 parts of physical foaming agent, and 500 parts of physical foaming agent dilution water.

Embodiment 3

[0081] The preparation method and steps are the same as in Example 1. The amounts of different components added are 900 parts of sulphoaluminate cement, 100 parts of fly ash, 3 parts of water reducer, 2 parts of cell regulator, and the slurry is thick. 6 parts of chemical regulator, 3 parts of fiber, 40 parts of foam stabilizer, 300 parts of mixing water, 7 parts of foam accelerator, 60 parts of chemical foaming agent, 30 parts of physical foaming agent, and 600 parts of physical foaming agent dilution water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com