Water reducing agent special for high-speed railway ballastless track self-compacting concrete

A technology of self-compacting concrete and ballastless track, which is applied in the field of special water-reducing agent for self-compacting concrete of high-speed railway ballastless track, can solve the problems of not being able to meet the requirements of construction, poor workability of concrete, and segregation of concrete, and achieve The effect of solving the problem of volume stability, good adaptability, and solving the problem of formulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

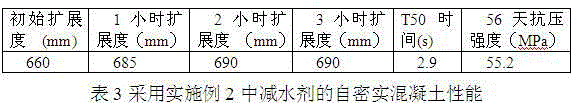

Examples

Embodiment 1

[0019] Take the common polycarboxylate superplasticizer mother liquor, and add it into water according to the calculated amount of the prepared total amount equivalent to a solid content of 4% to form a polycarboxylate superplasticizer solution with a solid content of 4%; then take 60-type slow-release polycarboxylate Water reducer mother liquor is also added to the solution according to the calculated weight of the prepared total amount equivalent to 2% solid content to form a solution with a total solid content of 6%; then take the 90-type slow-release polycarboxylate superplasticizer mother liquor, or according to the prepared The technical weight of the total amount equivalent to a solid content of 4.5% is also added to the solution to form an aqueous water reducer solution with a solid content of 10.5%. Add 2.5% sodium gluconate retarder to this aqueous solution according to the total amount, and then add 0.1% air getter and 0.05% air-entraining agent to the total weight o...

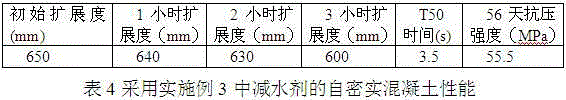

Embodiment 2

[0022] Take the common polycarboxylate superplasticizer mother liquor, and add it into water according to the calculated amount of the prepared total amount equivalent to a solid content of 4% to form a polycarboxylate superplasticizer solution with a solid content of 4%; then take 60-type slow-release polycarboxylate Water reducer mother liquor is also added to the solution according to the calculated weight of the prepared total amount equivalent to 3% solid content to form a solution with a total solid content of 7%; then take the 90-type slow-release polycarboxylate superplasticizer mother liquor, or according to the prepared The calculated weight equivalent to the total amount of 5% solid content is also added to the solution to form an aqueous water reducer solution with a solid content of 12%. Add 2% sodium gluconate retarder to this aqueous solution according to the total amount, and then add 0.1% air getter and 0.05% air-entraining agent to the total weight of the prep...

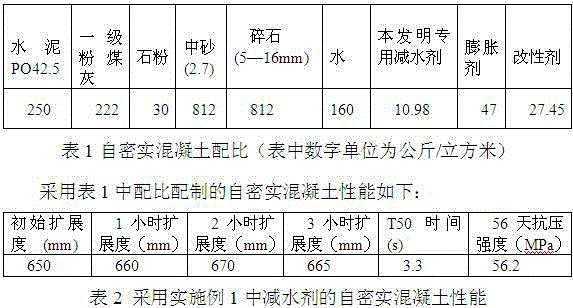

Embodiment 3

[0027]Take the common polycarboxylate superplasticizer mother liquor, and add it into water according to the calculated amount of the prepared total amount equivalent to a solid content of 4% to form a polycarboxylate superplasticizer solution with a solid content of 4%; then take 60-type slow-release polycarboxylate Water reducer mother liquor is also added to the solution according to the calculated weight of the prepared total amount equivalent to 1% solid content to form a solution with a total solid content of 5%; then take the 90-type slow-release polycarboxylate superplasticizer mother liquor, or according to the prepared The calculated weight of the total amount equivalent to a solid content of 4.5% is also added to the solution to form an aqueous water reducer solution with a solid content of 9.5%. Add 2.5% sodium tripolyphosphate retarder according to the total amount to this aqueous solution, and then add 0.1% air getter and 0.05% air-entraining agent to the total we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com