Servo ring shaping machine for wind protection ring

A wind protection ring and snare technology, which is applied in the field of machining, can solve the problems of substandard verticality and low efficiency of manual rounding of the wind protection ring.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

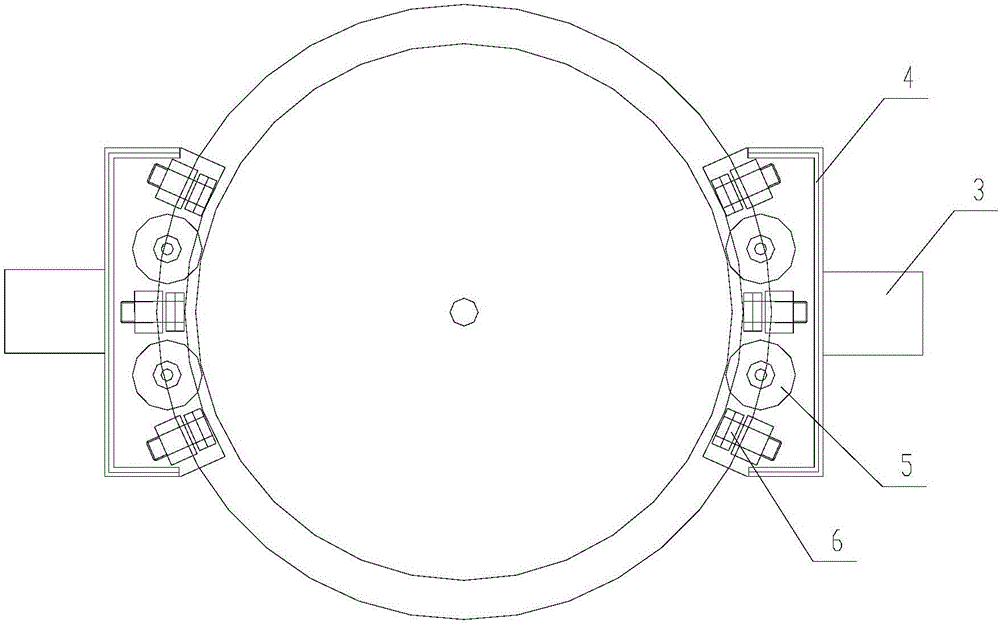

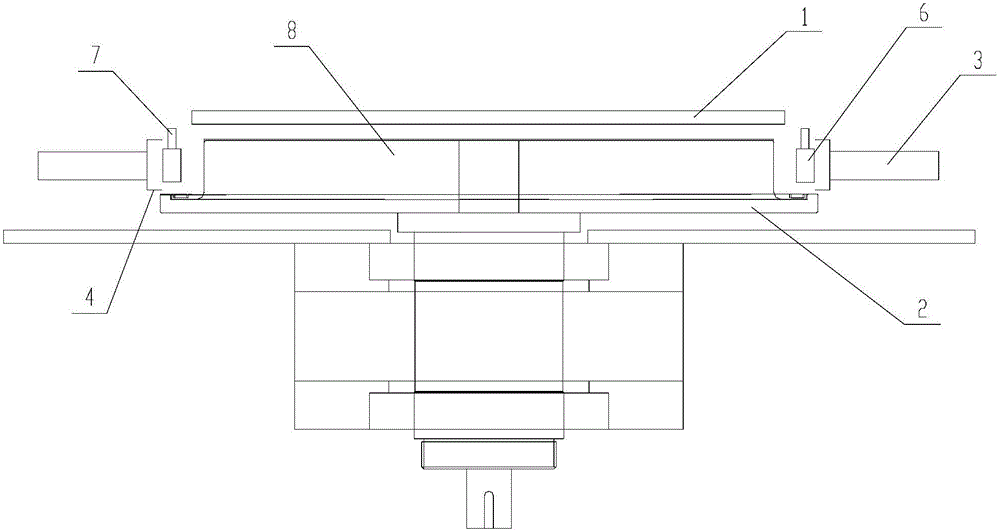

[0017] Such as figure 1 with 2 As shown in the figure, a wind protection ring servo-actuating complete coil machine includes a disc part and a shaping part. The shaping part is located on both sides of the disc part. Both the disc part and the shaping part are connected with the servo electric power system. The disc part includes an upper disc 1 and a lower disc 2. The lower disc 2 is provided with a wind guard seat 8, the wind guard seat 8 is covered with a wind guard to be shaped, and the upper disc 1 moves up and down in the vertical direction , The shaping part consists of a horizontal push-pull cylinder 3 and a roller groove 4. There are multiple shaping rollers in the roller groove 4. The shaping rollers are divided into roundness shaping rollers 5 and verticality shaping rollers 6, roundness The integral roller 5 is set horizontally, the verticality integral roller 6 is arranged vertically, the roundness integral roller 5 and the verticality integral roller 6 are arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com