Degassing device and method for battery thermal management system of pure electric vehicle

A battery thermal management, pure electric vehicle technology, applied in electric vehicles, battery/fuel cell control devices, control devices, etc., can solve the problems of slow filling, complicated cooling system pipelines, and low system degassing efficiency, and achieve Adjustable time, solving low efficiency and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

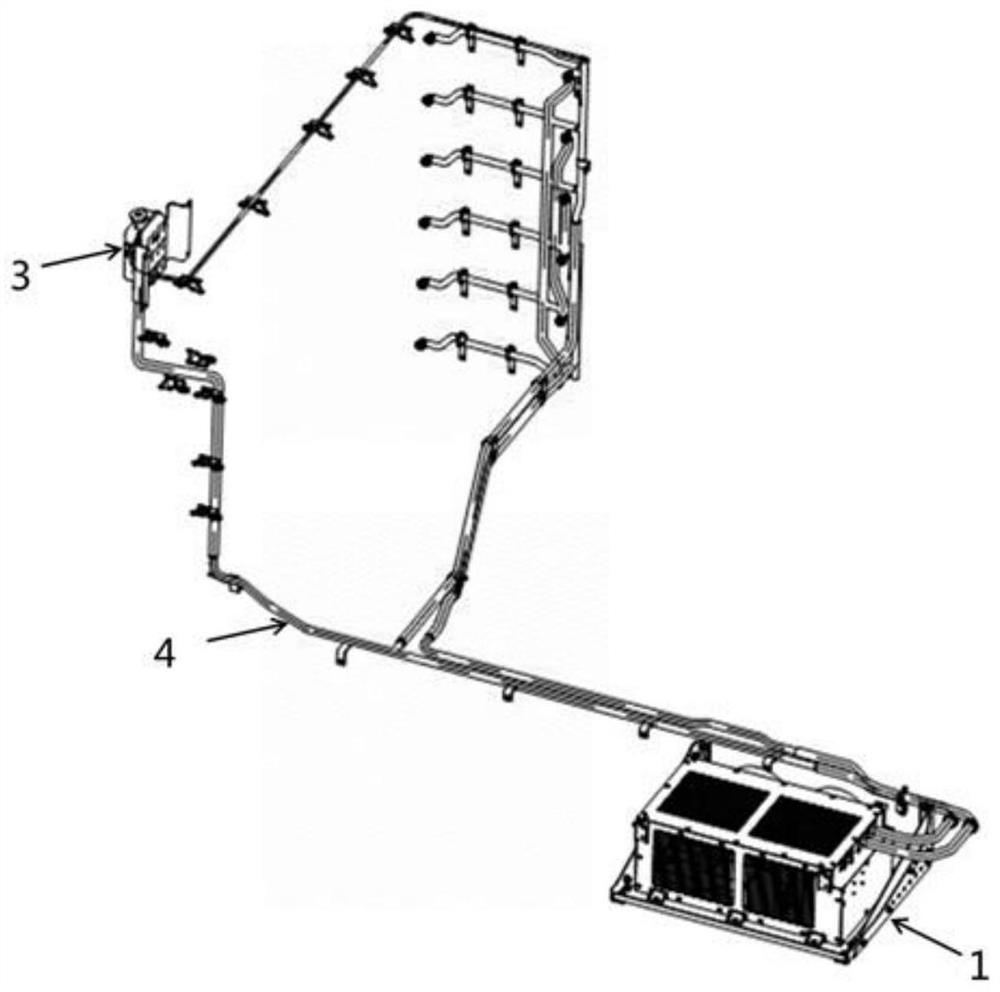

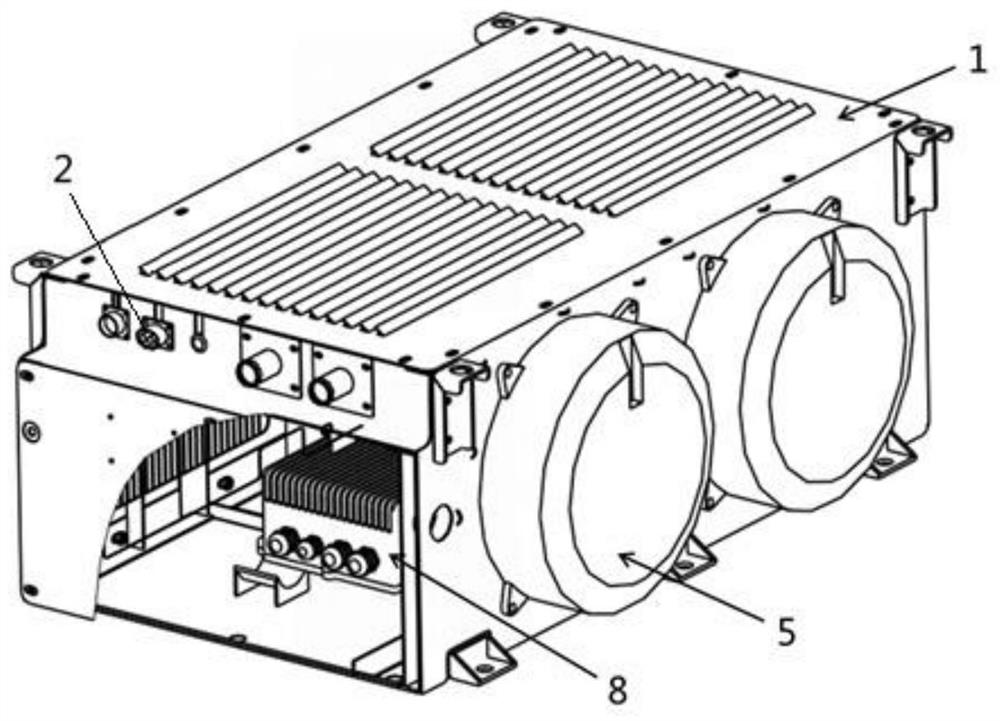

[0034] A degassing start-stop switch 2 is added to the battery thermal management system 1;

[0035] ① The protection level of the switch is not lower than IP67;

[0036] ②The function of the DC-DC power supply module 8 is to convert the high-voltage AC power of the vehicle into low-voltage DC power, and supply power to the system when the system is working;

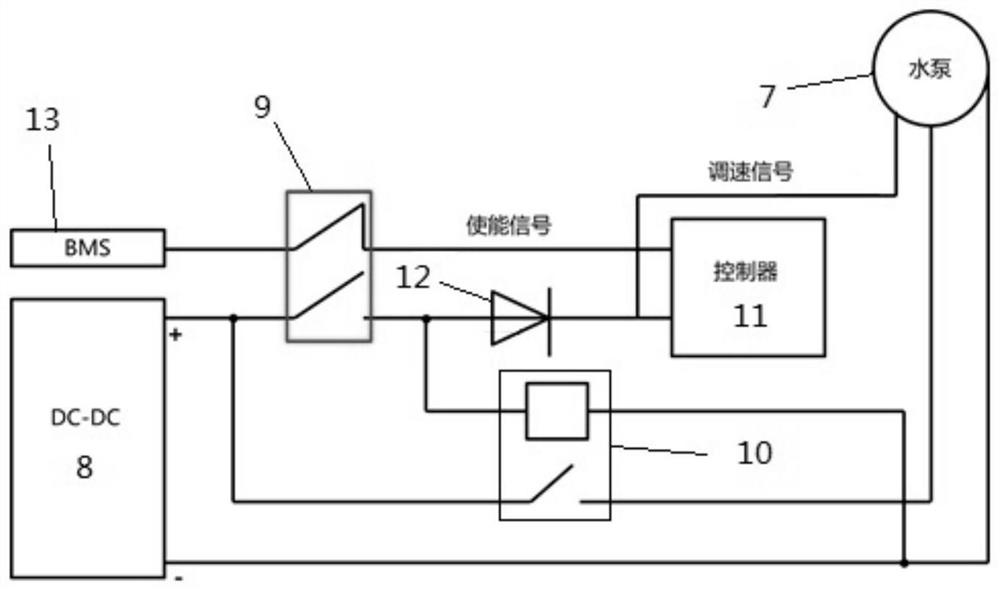

[0037] ③When the system starts, press the degassing start-stop switch 2, and the DC-DC power module 8 connects the external power supply to the cooling water pump 7; the enable signal of the BMS is turned off, at this time, the cooling water pump 7 in the battery thermal management system 1 work, start the automatic degassing function;

[0038] ④ The delay closing time of the degassing start-stop switch 2 is 5 minutes by default, and the delay closing time can be adjusted by flashing the control program of the controller 11 (the operation, stop and working time of the pump are controlled by the speed regulation signal);...

Embodiment 2

[0041] After the battery thermal management system 1 completes the automatic degassing working mode, it is necessary to manually press the degassing start-stop switch 2 again. At this time, the button is reset, and the external power supply to the cooling water pump by the DC-DC power module 8 is turned off; If the energy signal is turned on, the electrothermal thermal management system 1 can start the normal working mode (cooling, heating, self-circulation); otherwise, the battery thermal management system will not be able to start working.

Embodiment 3

[0043]① The degassing start-stop switch 2 is activated, and after the system starts filling the degassing function, in order to ensure the safety of the system, the battery thermal management system 1 itself is not allowed to operate. At this time, the enabling signal is disconnected, and the electronic fan 5 and compressor 6 are in sleep mode. state;

[0044] ②The cooling water pump 7 of the battery thermal management system runs at full speed by default after starting. In order to prevent the reverse control relay problem during actual operation, a diode 12 is added in the circuit to prevent the controller signal from reversely controlling the delay relay;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com