Positive electorde for secondary battery and lithium secondary battery including the same

A technology for secondary batteries and positive electrode current collectors, which is applied in the direction of secondary batteries, secondary battery repair/maintenance, battery electrodes, etc., which can solve problems such as the inability to fully ensure battery stability, and achieve the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0088] 40 parts by weight of LiFePO 4 Positive electrode active material, the carbon black of 10 weight parts as conductive agent, the carboxymethyl cellulose (CMC) of 3 weight parts and the polyethylene resin dispersion liquid of 47 weight parts are mixed in distilled water to prepare the first positive electrode active material slurry .

[0089] Additionally, 94 parts by weight of LiNi 0.6 mn 0.2 co 0.2 o 2 A positive active material, 3 parts by weight of carbon black as a conductive agent, and 3 parts by weight of PVdF as a binder were mixed in an N-methylpyrrolidone (NMP) solvent to prepare a second positive active material slurry.

[0090] A 20 μm thick water-based Al foil collector was coated with the first positive electrode active material slurry prepared above, and then dried to form a 10 μm thick first positive electrode active material layer. Subsequently, the second positive electrode active material slurry was coated on the first positive electrode active mat...

Embodiment 2

[0094] A positive electrode and a lithium secondary battery containing it were prepared in the same manner as in Example 1, except that 70 parts by weight of a polyethylene resin dispersion as a volume expansion resin and 17 parts by weight of LiFePO 4 positive electrode active material to prepare the first positive electrode active material slurry.

experiment example 1

[0102] Experimental Example 1: Overcharge Test

[0103] The overcharge test was performed by using the secondary batteries prepared in Examples 1 and 2 and Comparative Examples 1 to 3. Specifically, each secondary battery was charged at 0.3C to the full charge voltage (4.25V) and charged at 0.05C. Subsequently, each secondary battery was overcharged at 1C to a voltage of 6.4V after allowing each secondary battery to pass through a rest time of 3 hours to stabilize the voltage.

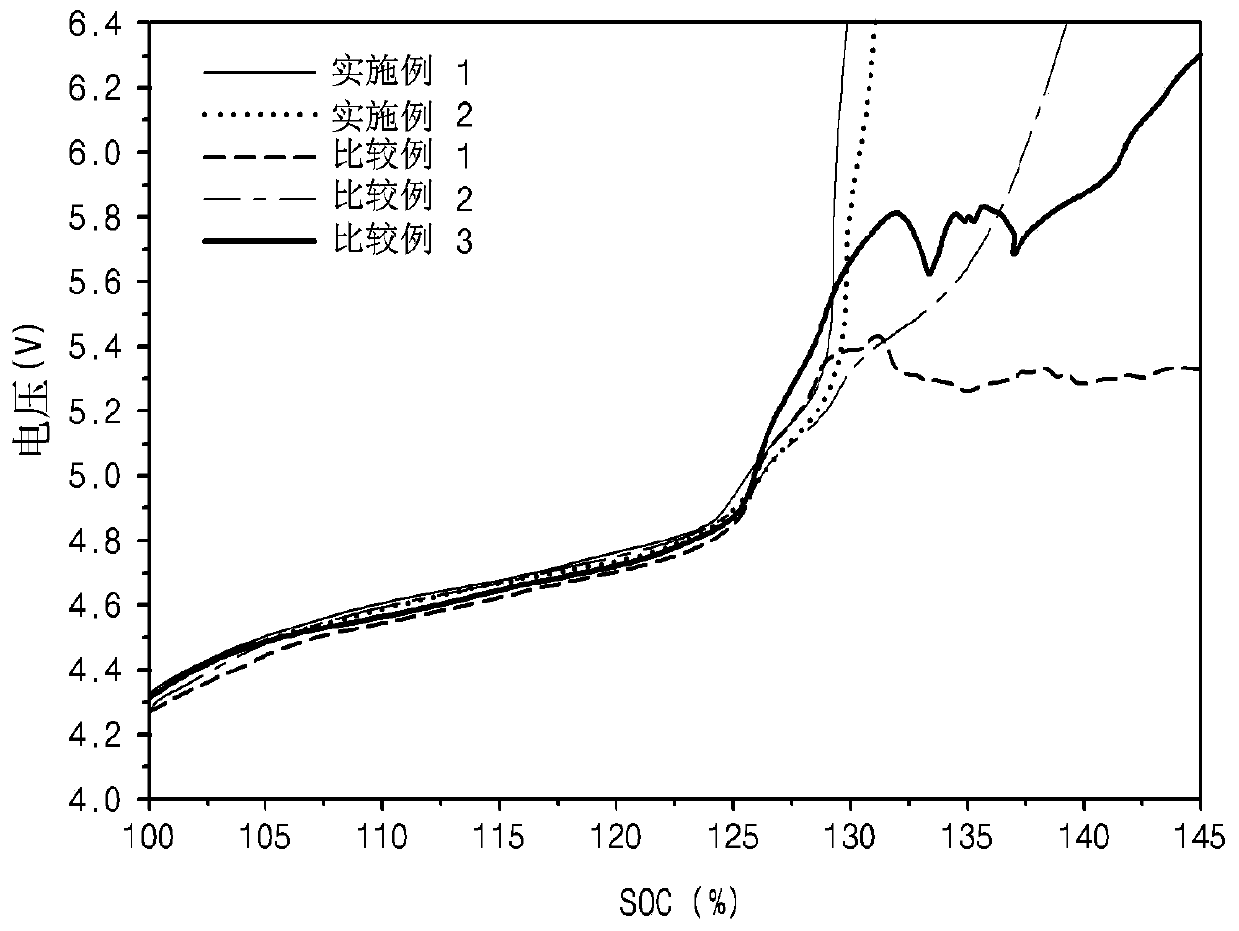

[0104] In this regard, figure 1 is a graph showing overcharge test results of lithium secondary batteries prepared in Examples 1 and 2 and Comparative Examples 1 to 3 of the present invention.

[0105] Such as figure 1 As shown, for the lithium secondary batteries prepared in Examples 1 and 2, it was confirmed that the voltage increased rapidly above 4.8 V, and therefore, it was considered that the overcharge termination voltage was reached quickly.

[0106] In particular, for Example 1, since the mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com