Mechanical arm overturning and clamping mechanism of construction machinery

A technology for construction machinery and clamping mechanism, applied in the directions of manipulator, claw arm, chuck, etc., can solve the problems of poor stability of the manipulator, potential safety hazards, reduce the practicability of the clamping mechanism, etc., achieve good stability, improve safety, The effect of improving usability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

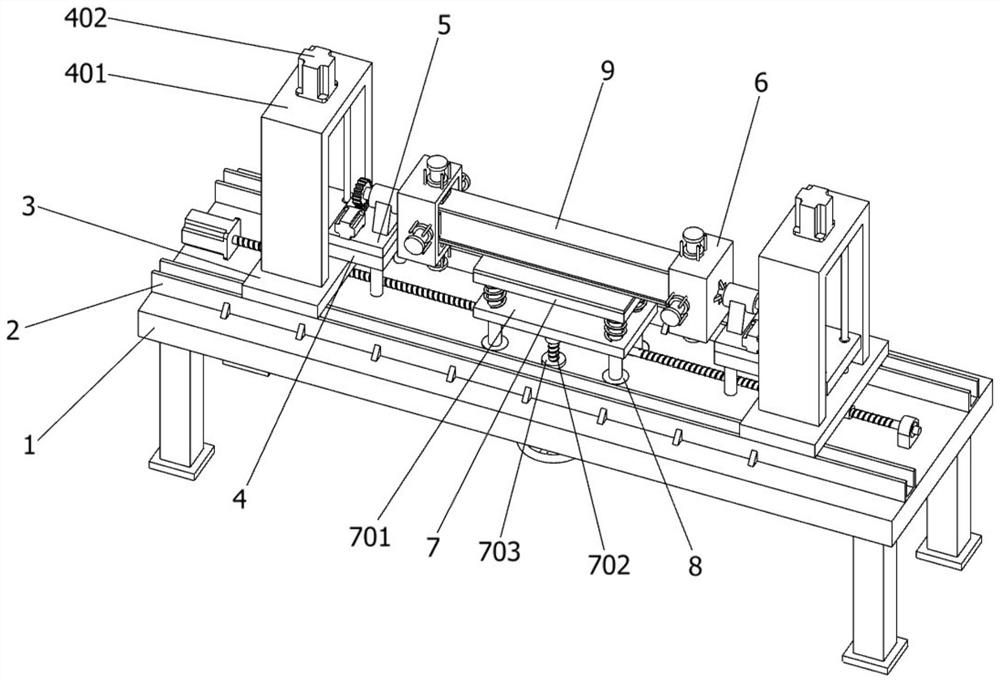

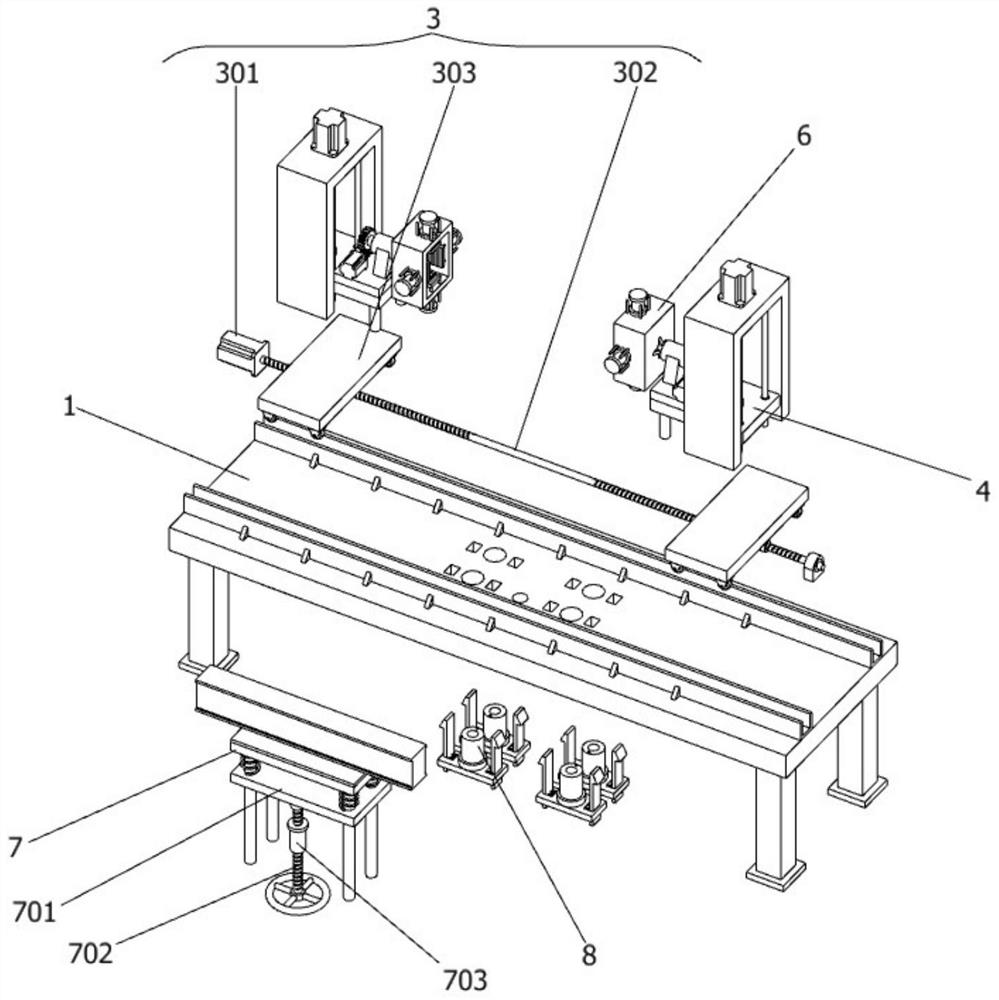

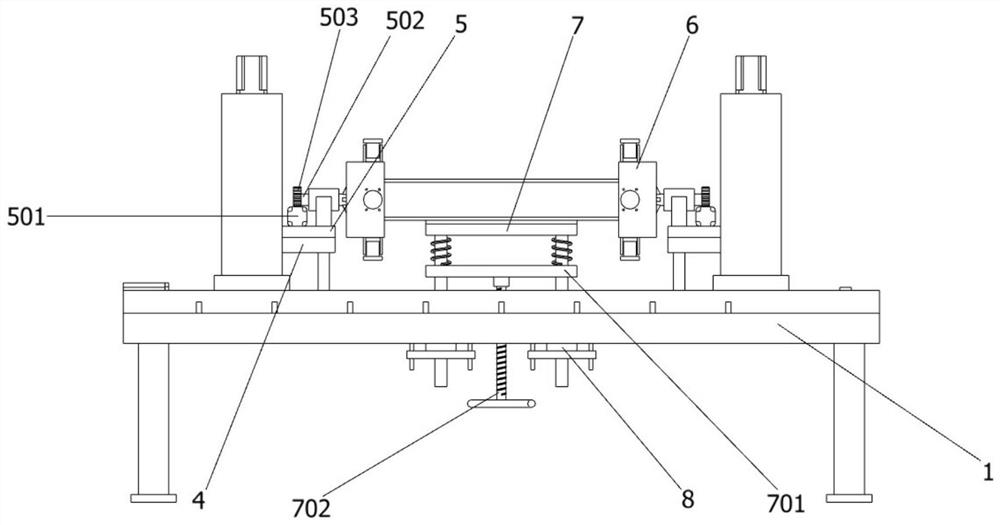

[0033] as attached figure 1 to attach Figure 8 Shown:

[0034] The invention provides a mechanical arm turning and clamping mechanism for construction machinery, which includes: a platform 1, the upper end surface of the platform 1 is symmetrically provided with two 匚-shaped slide rails 2, and the upper part of the platform 1 is provided with a distance adjustment Mechanism 3, the distance adjustment mechanism 3 includes an adjustment motor 301, a distance adjustment screw 302, a moving plate 303 and a directional wheel 304, the adjustment motor 301 is installed on the left side of the upper end face of the stand 1, and the adjustment motor 301 is connected with a distance adjustment screw through a rotating shaft 302, the outside of the distance adjustment screw 302 is provided with two reverse threads, and the outside of the distance adjustment screw 302 is connected with two moving plates 303 through two reverse threads, and the middle part of the bottom end surface of ea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com