Method for manufacturing AlGaN-GaN heterojunction ohmic contact

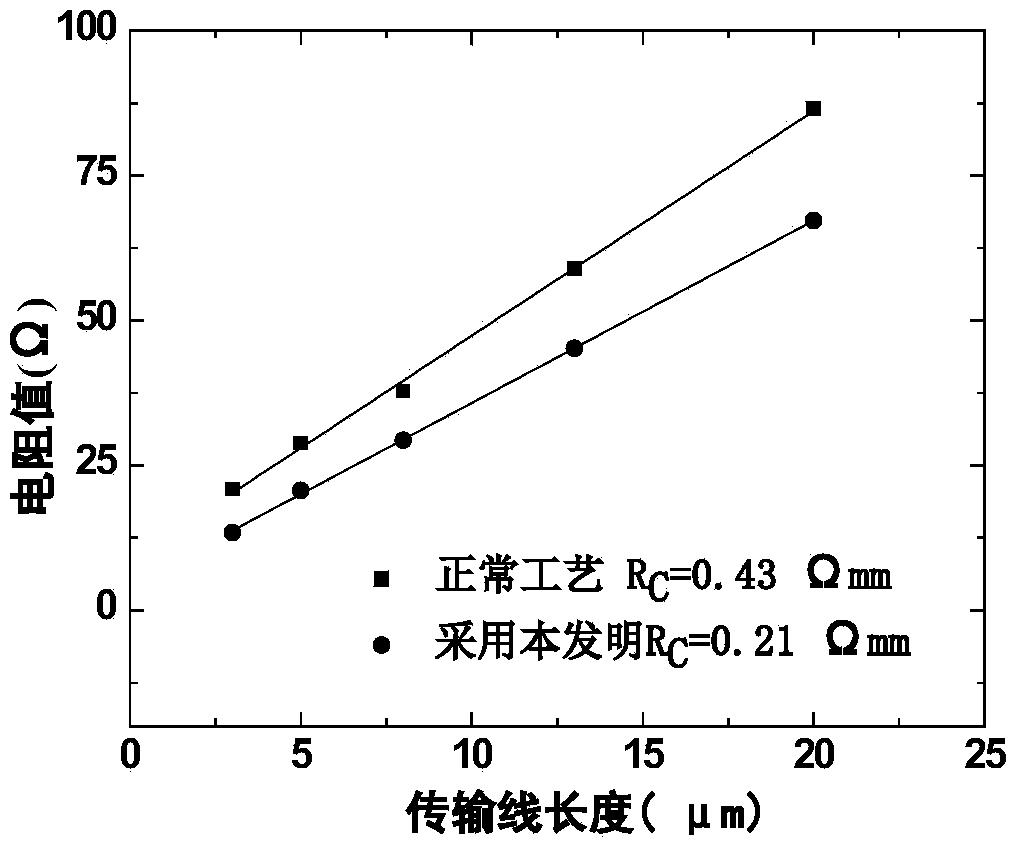

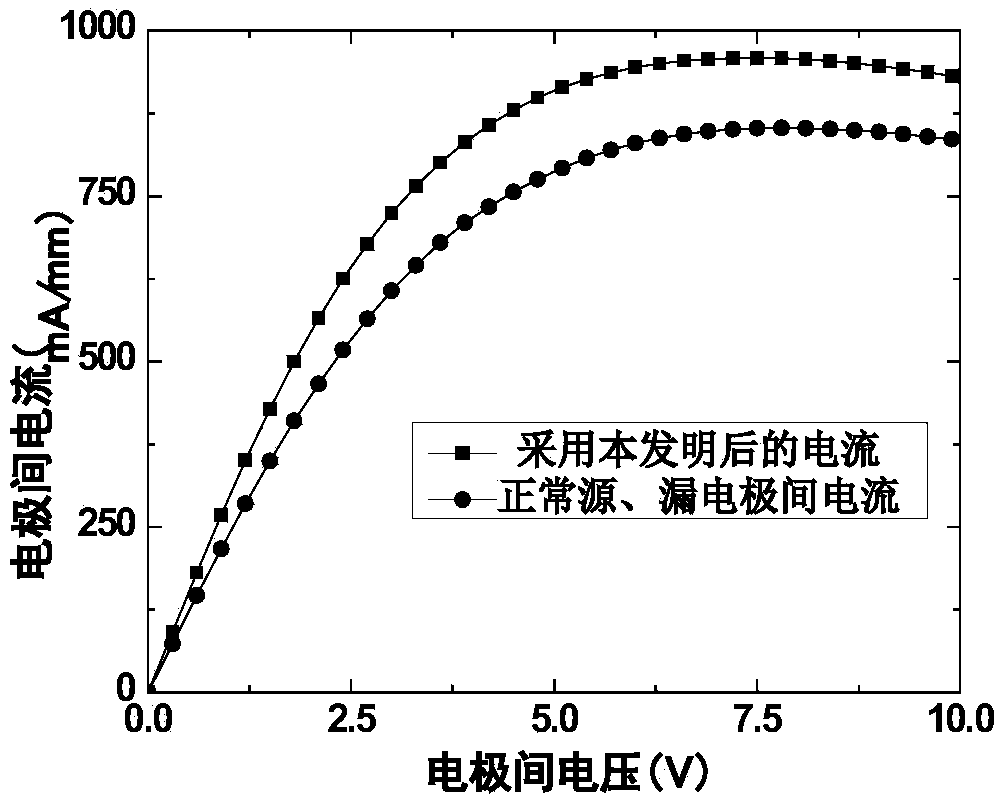

A technology of ohmic contact and manufacturing method, which is applied in the field of microelectronics, can solve the problems of limited improvement of ohmic contact, achieve the possible effects of no stability problem, reduce ohmic contact resistance, and increase tunneling current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Embodiment 1: Fabricate an ohmic contact with a hole depth of 5nm and a metal Ti / Al / Ni / Au thickness of 20nm / 150nm / 40nm / 60nm.

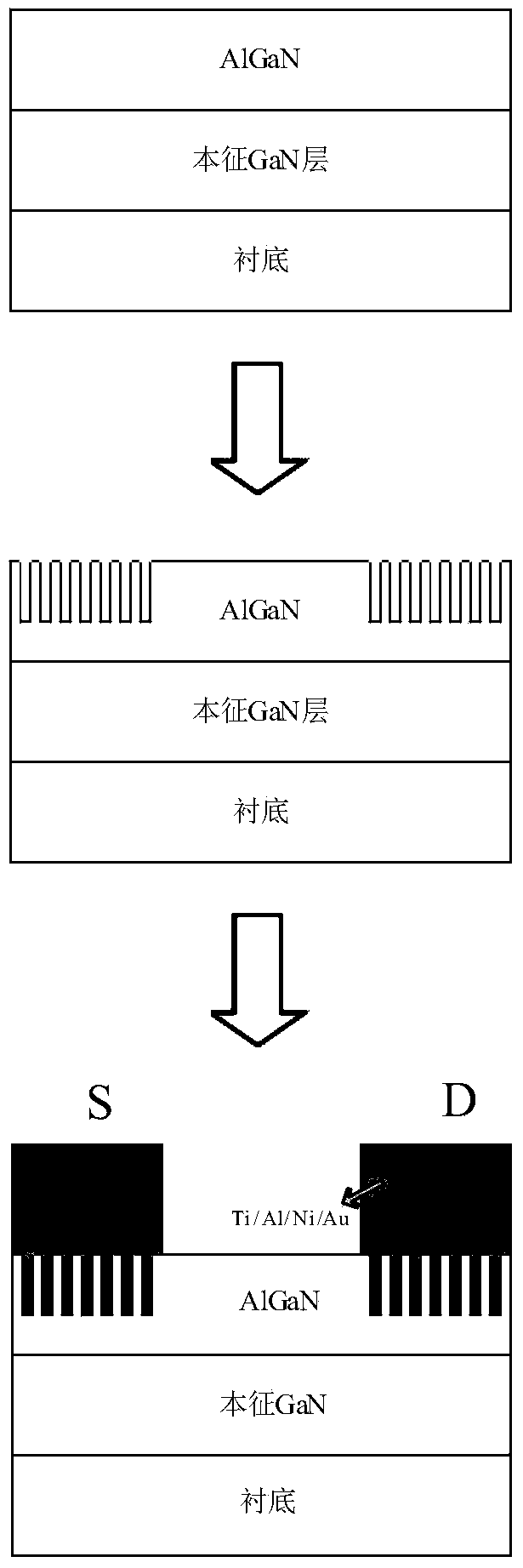

[0041] refer to figure 1 , the implementation steps of this example are as follows:

[0042] Step 1. Cleaning the AlGaN / GaN heterojunction material sample.

[0043] 1.1) Place the AlGaN / GaN heterojunction material sample in a 1:5 HF solution and soak for 30s to remove the surface oxide layer;

[0044] 1.2) The AlGaN / GaN heterojunction material sample was ultrasonically cleaned in acetone and ethanol organic solvents to remove surface contamination, and rinsed with deionized water for 5 minutes.

[0045] Step 2. Dig holes in the ohmic electrode area.

[0046] 2.1) Throw 0.6 μm positive glue EPI621 on the surface of the cleaned AlGaN / GaN heterojunction material sample at a speed of 5000 rpm with a glue throwing machine, and then put the glued AlGaN / GaN heterojunction material into the temperature Dry in a high-temperature oven at 110°C for 1mi...

Embodiment 2

[0056] Example 2: Fabricate an ohmic contact with a hole depth of 10 nm and a metal Ti / Al / Ni / Au thickness of 25 nm / 200 nm / 50 nm / 80 nm.

[0057] refer to figure 1 , the implementation steps of this example are as follows:

[0058] Step 1. Cleaning the AlGaN / GaN heterojunction material.

[0059] This step is the same as Step 1 in Example 1.

[0060] Step 2. Dig holes in the ohmic electrode area.

[0061] (2a) Spray 0.6 μm positive glue EPI621 on the surface of the cleaned AlGaN / GaN heterojunction material. The GaN heterojunction material is dried for 1 min, then exposed with an NSR1755I7A photolithography machine, and finally developed to obtain a photoresist mask with several through holes distributed in the ohmic electrode area. The sum of the areas of these through holes is the total area of the ohmic contact electrodes 30% of;

[0062] (2b) Etch the AlGaN material exposed in the through hole of the photoresist mask with an RIE plasma dry etching machine, and the etchi...

Embodiment 3

[0071] Example 3: Fabricate an ohmic contact with a hole depth of 15 nm and a metal Ti / Al / Ni / Au thickness of 30 nm / 250 nm / 60 nm / 100 nm.

[0072] refer to figure 1 , the implementation steps of this example are as follows:

[0073] Step A. Cleaning the AlGaN / GaN heterojunction material.

[0074] This step is the same as Step 1 in Example 1.

[0075] Step B. Dig holes in the ohmic electrode area.

[0076](B1) Put the cleaned AlGaN / GaN heterojunction material into the glue-spinning machine, adjust the speed of the glue-spinning machine to 5000 rpm, and throw the positive glue EPI621 on the surface of the cleaned AlGaN / GaN heterojunction material. The AlGaN / GaN heterojunction material that has been glued is dried in a high-temperature oven at a temperature of 110°C for 1 min, then exposed with an NSR1755I7A photolithography machine, and finally developed to obtain an ohmic electrode area with several A photoresist mask for through holes, the sum of the areas of these through h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com