Continuous fibrous globule filter and its filtering method

A technology of fiber balls and filters, applied to loose filter material filters, filtration separation, separation methods, etc., can solve whether compaction and compaction are different, difficult to control, difficult to completely remove dirt, and unable to achieve loosening, etc. problems, to achieve the effect of easy automatic control, water content reduction, and easy cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

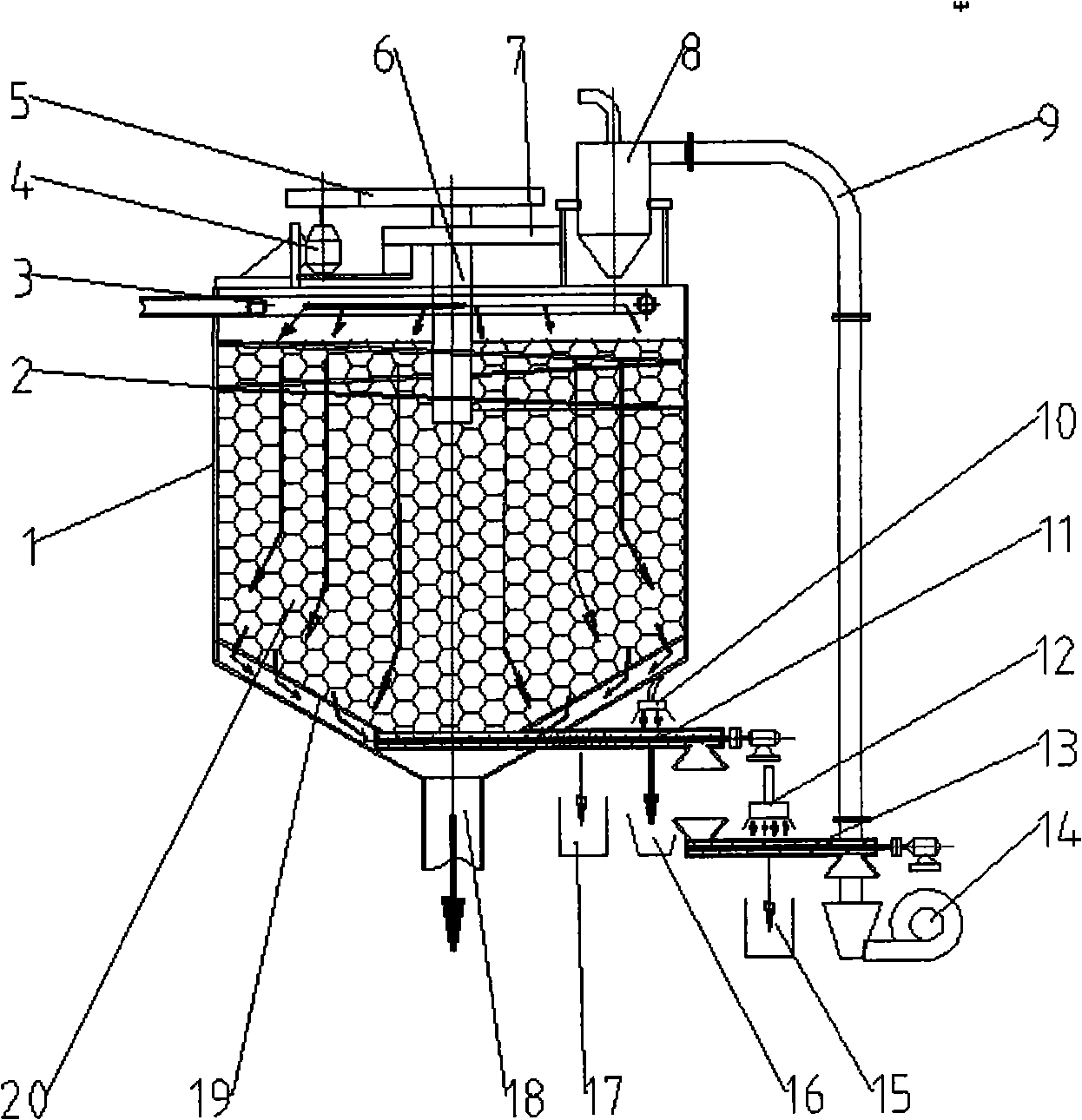

[0030] exist figure 1 Among them, the frame 7 is installed on the upper end surface of the housing 1 with bolts. The pressing and conveying screw shaft 6 is fixed on the frame 7 with a bearing seat, and is concentric with the center line of the cylindrical body 1. The compression conveying screw 2 is welded on the compression conveying screw shaft 6, the screw is not less than two turns, the total height of the screw is not greater than one-fifth of the cylindrical part of the shell, and the annular gap between the outer diameter of the spiral and the inner surface of the shell is less than 5mm, with 5mm through holes evenly distributed on the helical surface. Compress conveying screw motor 4 and be fixed on the frame 7 with screw pair. The driving shaft and the output shaft of the pressing and conveying screw reduction mechanism 5 are respectively connected with the pressing and conveying screw motor 4 and the pressing and conveying screw shaft 6 .

[0031] The sewage dist...

Embodiment 2

[0038] exist figure 1 The sewage can enter from the bottom, and the sewage distribution pipe 3 is installed at the junction of the cone and the cylinder of the housing 1, the sewage is filtered during the upward floating process, and the clean water overflows from the upper part of the housing 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com