Anti-blockage sewage filter

A filter device and anti-clogging technology, applied in the field of mechanical equipment, can solve the problems of rapid equipment depreciation, filter equipment and pipeline blockage pollution, high work intensity, etc., achieve continuous filtration process, stable and reliable equipment operation, and avoid filter blockage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

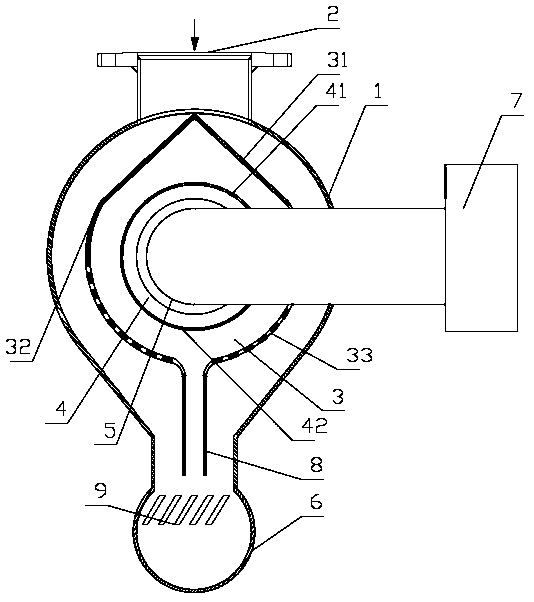

[0018] like figure 1 As shown: the sewage anti-clogging filter device of this embodiment includes a housing 1, the upper part of the housing is provided with a water inlet 2, and the inside of the housing is provided with a first filter chamber 3, and the inside of the first filter chamber is A second filter chamber 4 is provided, the second filter chamber is connected to the water outlet 5, and the bottom of the housing is provided with a sedimentation tank 6;

[0019] The first filter chamber includes a herringbone deflector 31 at the top centered at the water inlet, first blind plates 32 connected to the deflector at both sides, and a first net plate at the bottom 33;

[0020] The second filter chamber includes a second mesh plate 41 at the top and a second blind plate 42 at the bottom;

[0021] The water outlet is connected with a water outlet pipe, and the water outlet pipe is connected with a water pump 7 .

[0022] In the sewage anti-clogging filter device described ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com