Quenching collection and treatment system based on smelting flue gas

A smelting flue gas and treatment system technology, which is applied in the field of smelting flue gas treatment, can solve the problems of broken filter screen, dust filter cleaning, and inability to guarantee the concentration, etc., and achieve the effects of improving absorption capacity, good cooling treatment, and ensuring filtration strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

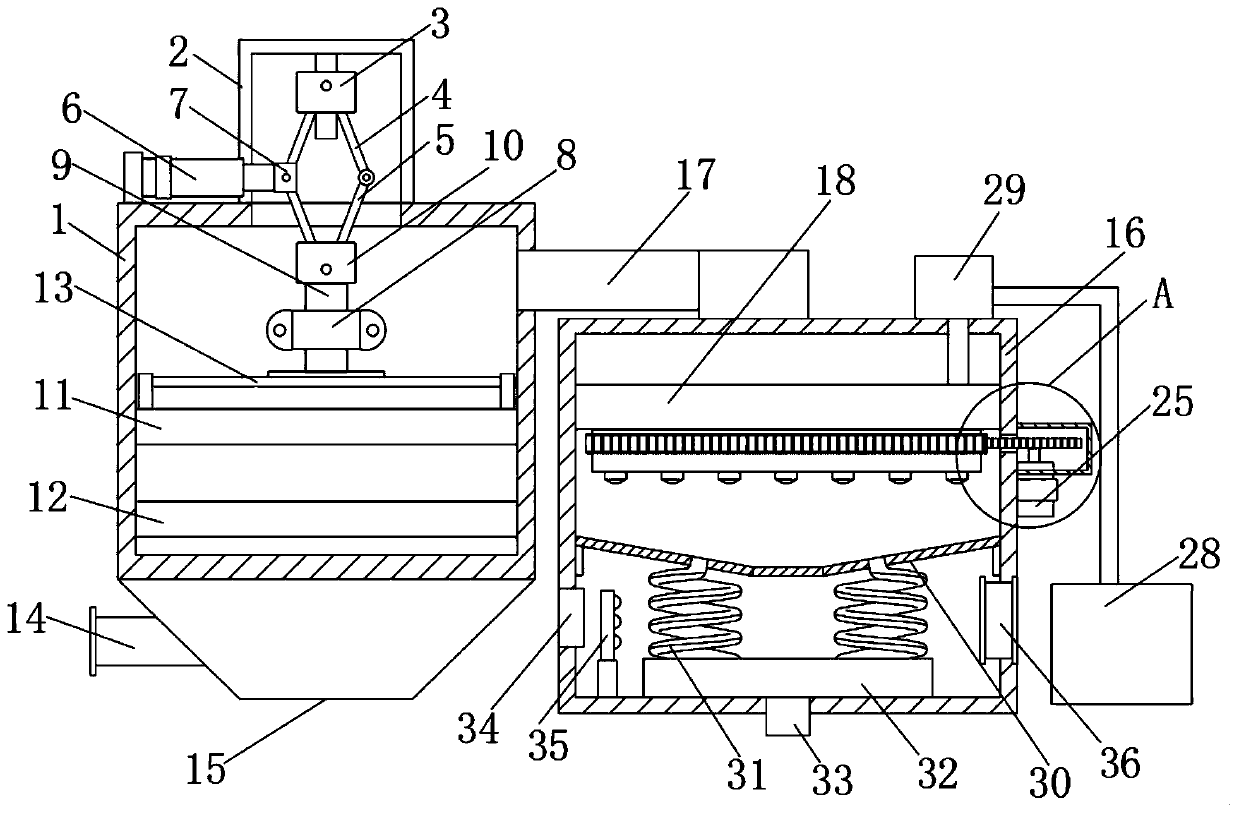

[0027] see Figure 1-5, a quenching collection and processing system based on smelting flue gas, including a filter box 1, a treatment box 16 and a lye storage tank 28, a connection box 2 is fixedly connected to the top of the filter box 1, and a first installation block 3 is arranged inside the connection box 2 , and the first installation block 3 is slidably connected to the side wall of the spool, the first installation block 3 is rotatably connected with two first rotating rods 4 through the rotating shaft, and one end of the two first rotating rods 4 is rotatably connected with a second rotating rod 4 Rod 5, a hydraulic cylinder 6 is fixedly installed on the side wall of the connection box 2, the output end of the hydraulic cylinder 6 is fixedly connected with a fixing member 7, and the rotating shaft between the first rotating rod 4 and the second rotating rod 5 is fixedly connected in the fixing member 7, An installation cylinder 8 is fixedly connected inside the filter...

Embodiment 2

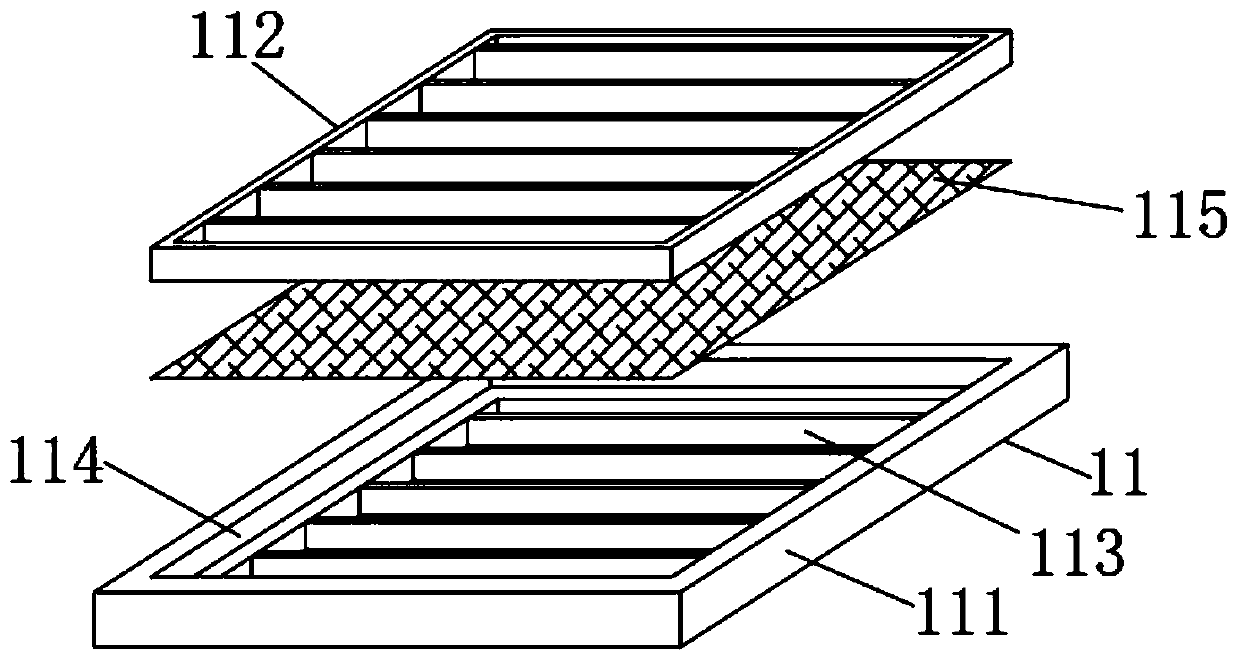

[0030] see Figure 1-5 , on the basis of Embodiment 1, a further improvement has been made: the inner wall of the filter box 1 is fixedly connected with a second filter frame 12, and the second filter frame 12 is located below the first filter frame 11; the first filter frame 11 includes a frame 111 With the fitting frame 112 , a plurality of fixing plates 113 are fixedly connected to the inner side of the frame 111 and the inner side of the fitting frame 112 , a fitting groove 114 is opened at the top of the frame 111 , and the fitting frame 112 is matched and installed in the fitting groove 114 , and the frame 111 and the fitting frame 112 A filter screen 115 is installed therebetween.

[0031] In this embodiment, it is convenient to filter the dust through the cooperation of the first filter frame 11 and the second filter frame 12. The filter screen 115 is installed between the frame 111 and the fitting frame 112, and then the filter screen 115 is cleaned by the fixing plat...

Embodiment 3

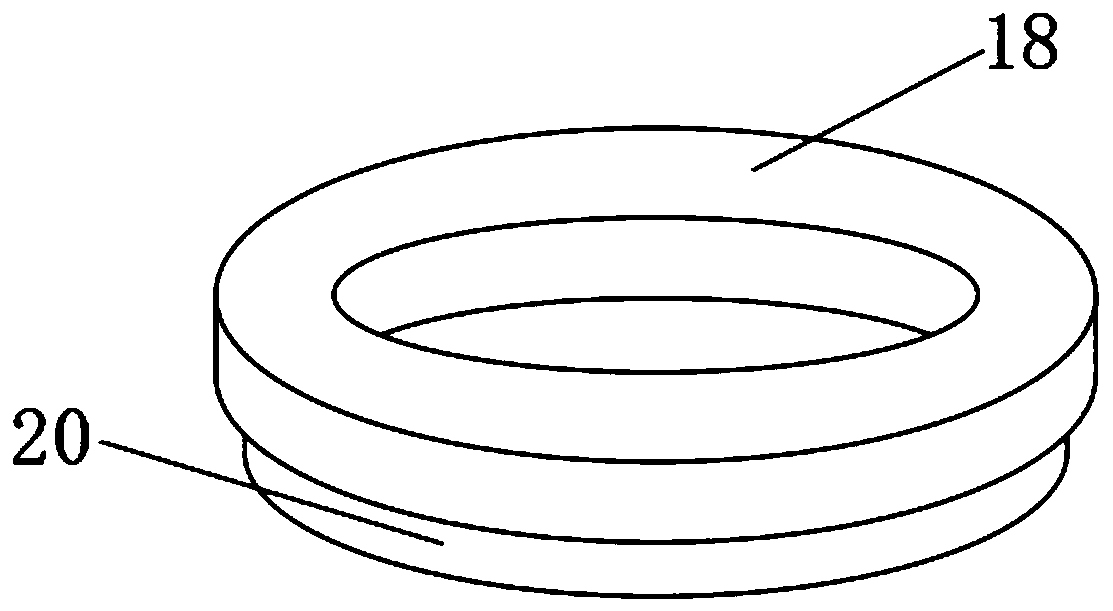

[0033] see Figure 1-5 , on the basis of Embodiment 1, a further improvement has been made: the inner side of the fixed ring 18 is provided with a sliding groove 19, the annular frame 20 is rotatably connected to the inner side of the fixed ring 18, the side wall of the annular frame 20 is fixedly connected with a sliding ring 21, and the sliding ring 21 The matching sliding connection is in the sliding groove 19, the spray head 23 is fixedly installed on the bottom end of the ring frame 20, the side wall of the ring frame 20 is fixedly connected with a rack 24, the side wall of the processing box 16 is fixedly installed with a drive motor 25, and the drive motor 25 outputs The end is fixedly connected with a driving tooth 26, and the driving tooth 26 is engaged with the rack 24; a pump body 29 is fixedly installed on the top side of the processing box 16, and the input end of the pump body 29 is connected to the lye storage tank 28 through a pipeline, and the pump body 29 The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com