Recycled plastic melt filter

A melt filter and recycled plastic technology, applied in the field of filters, can solve the problems of low processing efficiency and less clean melt plastics of non-mesh filters, and achieve good passability, small pressure fluctuations, and reduce pollution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

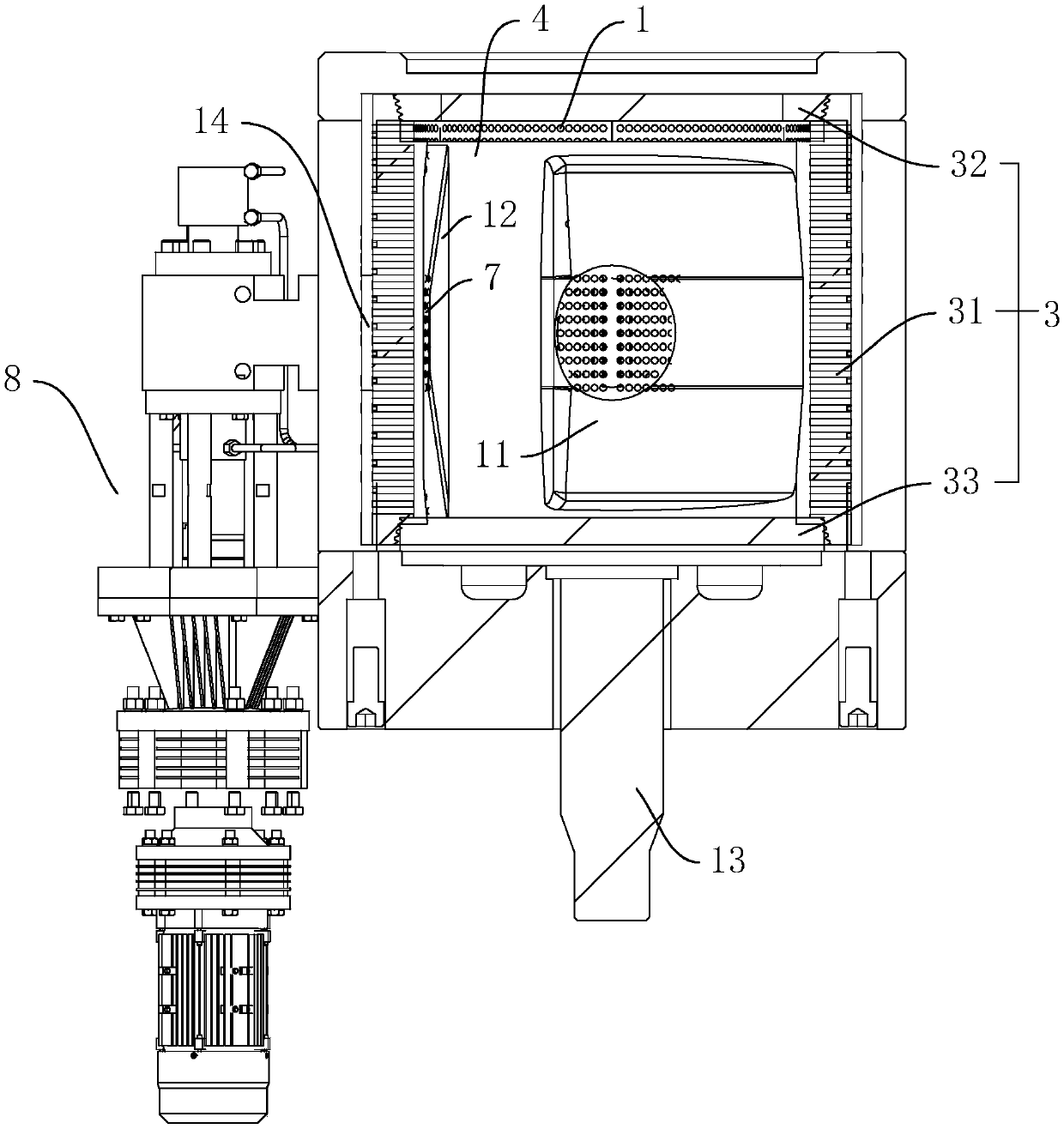

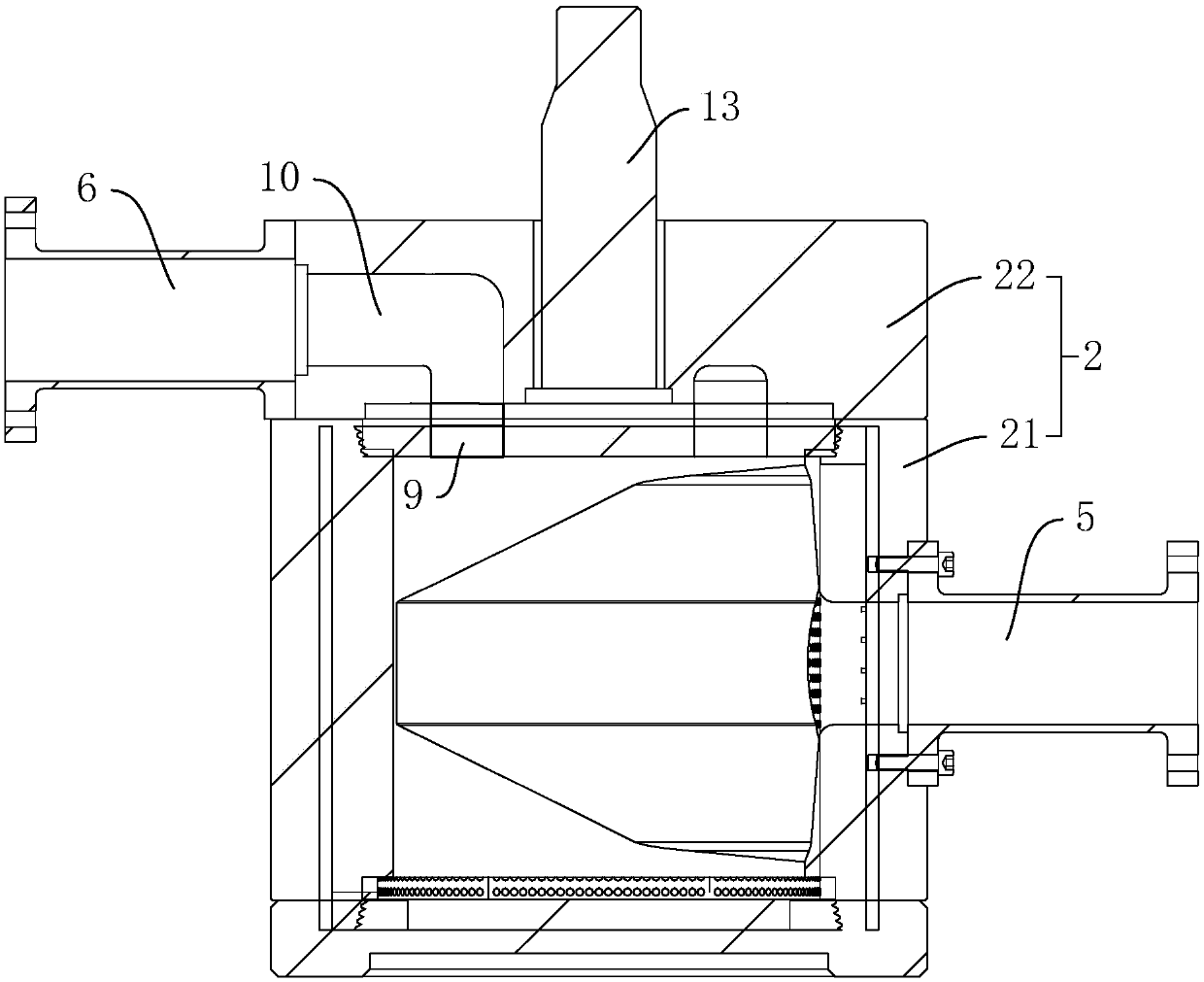

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings.

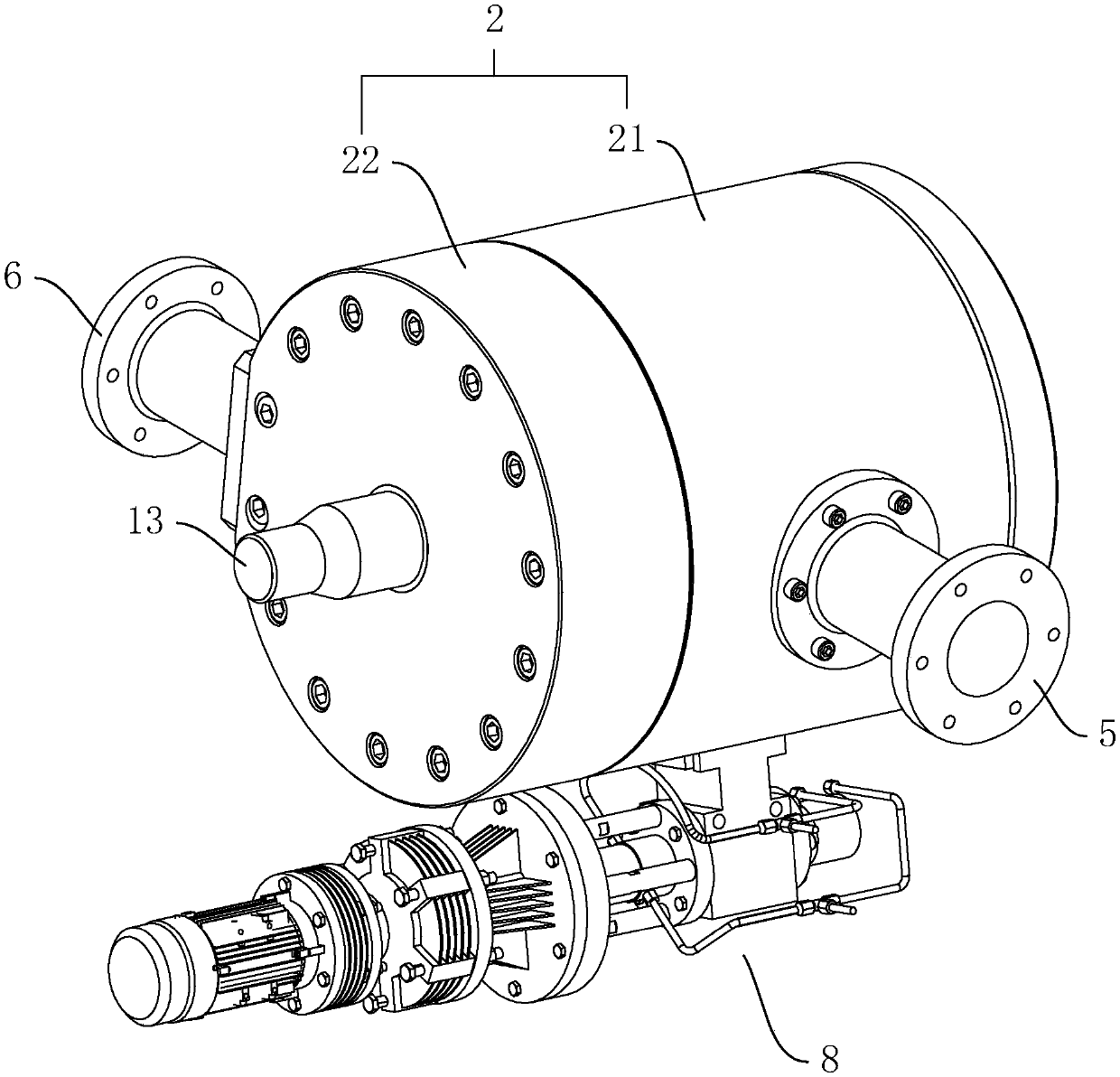

[0024] A recycled plastic melt filter such as Figure 1 to Figure 3 As shown, it includes a cylinder body 2 with an inner cavity. The cylinder body 2 is composed of a cylinder holder 21 with an opening and a cylinder cover 22 for covering the opening, and the cylinder cover 22 is connected to the end of the cylinder holder 21 by screw compression. department.

[0025] A feed pipe 5 is connected to the side wall of the cartridge holder 21 , and the feed pipe 5 is arranged along the radial direction of the cartridge holder 21 , and the feed pipe 5 communicates with the inner cavity of the cylinder body 2 . The cylinder holder 21 is also provided with a miscellaneous outlet 7 extending radially along the cylinder holder 21, the miscellaneous outlet 7 is connected to the inner cavity of the cylinder body 2, and the miscellaneous outlet 7 is provided with a misce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com