Oil filtering and cooling device for hydraulic oil cylinder

A technology of a cooling device and a hydraulic cylinder, which is applied in the field of hydraulic cylinders, can solve the problems of reduced service life of hydraulic cylinders, reduced service life of hydraulic cylinders, reduced cleanliness of hydraulic oil, etc., and achieves the effect of increasing service life and realizing cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

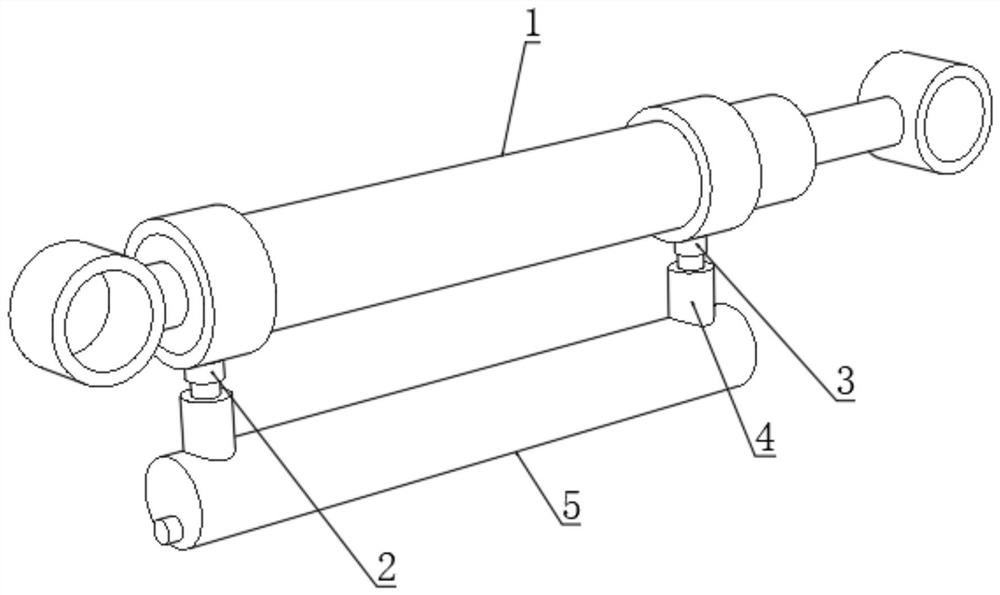

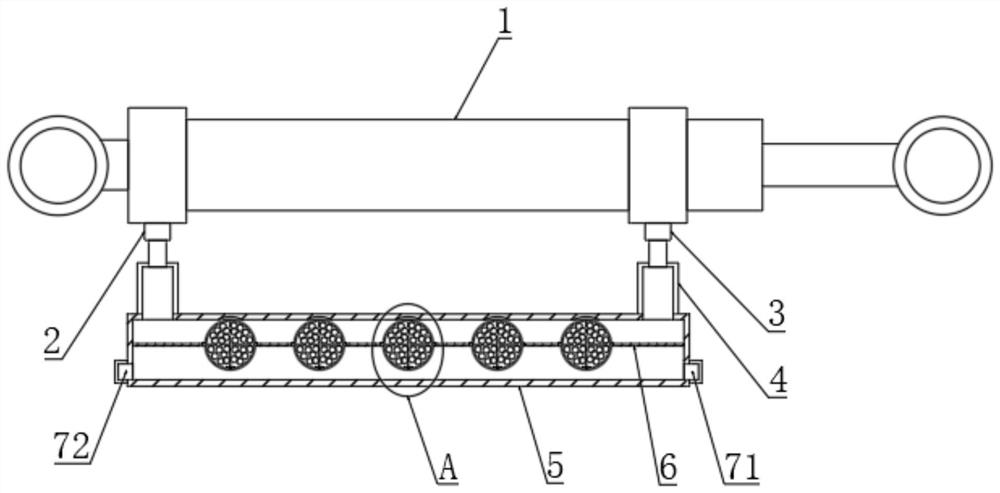

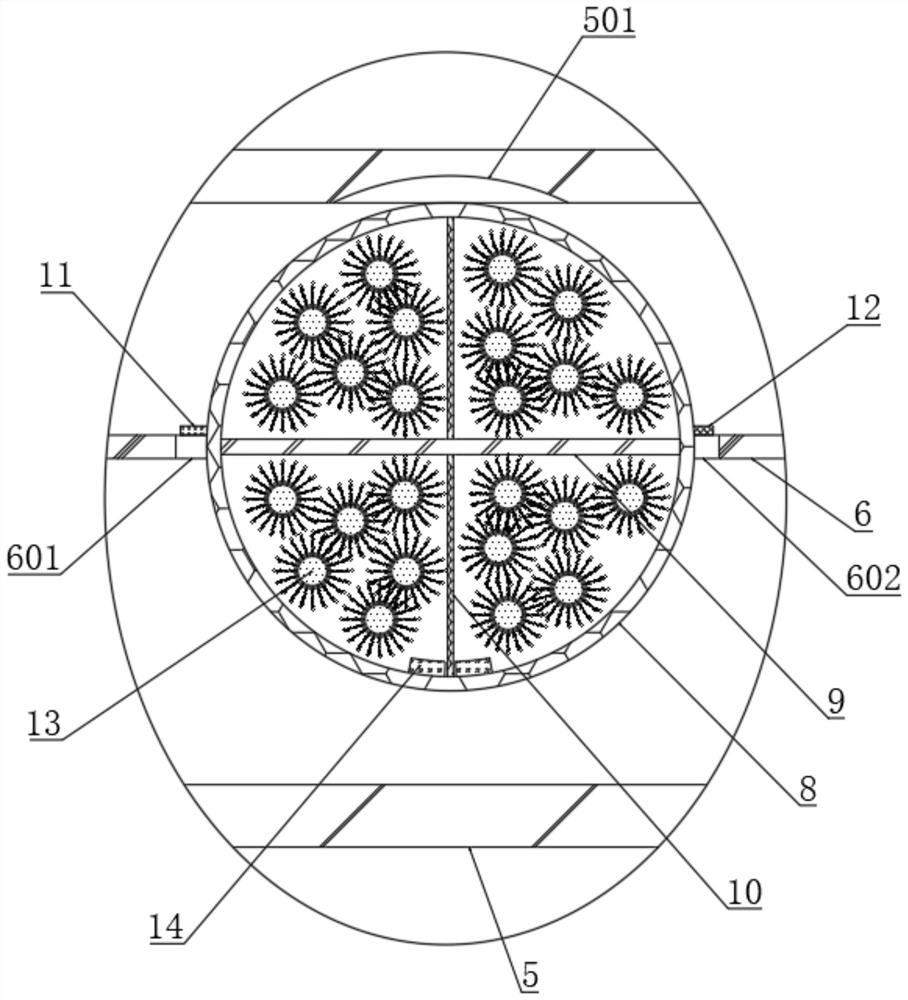

[0043] see figure 1 and figure 2 , an oil filtering and cooling device for a hydraulic cylinder, comprising a cylinder body 1 and a double-chamber pipe 5 connected to the cylinder body 1, the cylinder body 1 is fixedly connected with an oil injection pipe 2 and an oil outlet pipe 3, and the oil injection pipe 2 and the outlet pipe Both the oil pipe 3 and the double-lumen tube 5 are fixedly connected with a connecting pipe 4, and the connecting pipe 4 communicates with the inside of the double-lumen pipe 5, and the inside of the double-lumen pipe 5 is fixedly connected with a partition 6, and the partition 6 divides the inner portion of the double-lumen pipe 5. The upper part is for the flow of hydraulic oil, and the lower part holds the cooling and cleaning oil, and the cooling and cleaning oil is the same type of oil as the hydraulic oil, so that even if part of the cooling and cleaning oil is mixed into the hydraulic oil, it is not easy The use of the cylinder 1 is affecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com