Flushing-free multistage high efficiency filter

A high-efficiency filter and no-rinse technology, which is applied to fixed filter element filters, filtration separation, chemical instruments and methods, etc., can solve the problems of wasting water resources, polluting water bodies, reducing filtration productivity, etc., and achieves increasing water flow and filtration The effect of increasing quantity and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

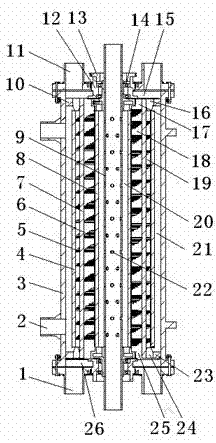

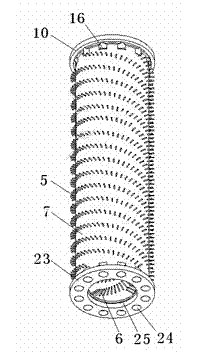

[0018] Such as figure 1 , figure 2 , the rinse-free multi-stage high-efficiency filter provided by the present invention comprises a housing 3 with a liquid inlet 11, a liquid outlet 1 and a water outlet 2 on it, an inner filter membrane column 8 and an outer filter membrane set in the housing 3. The membrane column 4 is located on the inner side of the inner filter membrane column 8 and the outer side of the outer filter membrane column 4. An inner filter water channel 20 and an outer filter water channel 21 are respectively provided. The inner water outlet pipe 9 with a through hole 22, the outer filtered water channel 21 communicates with the water outlet 2 on the shell 3, and a rotating brush roller with inner and outer brushes is arranged between the inner and outer filter membrane columns 8 and 4 7. The upper end of the rotating brush roller 7 is provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com