Removal of ammonia in urea finishing

一种尿素、物理吸附的技术,应用在除去氨领域,能够解决没有解决氨解吸附吸附剂再生问题等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

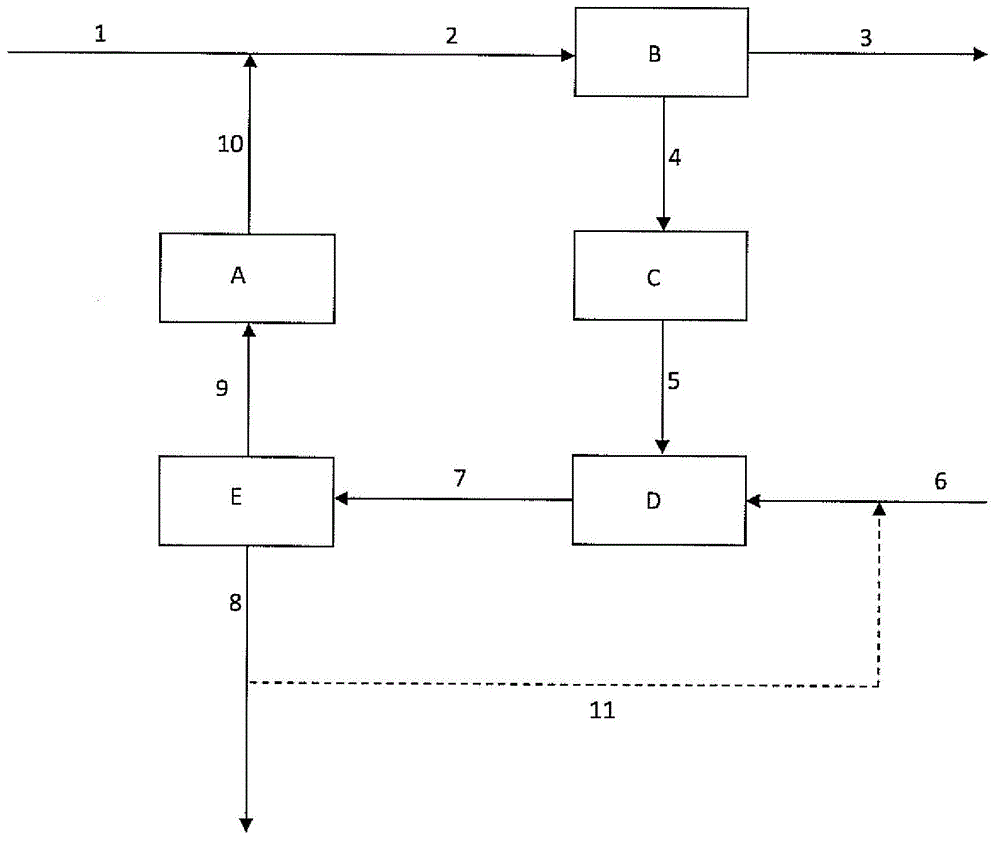

[0087] refer to figure 1 Schematic given, the exemplary process utilizes a baghouse filter with a pneumatic dust conveyor, a dust silo with a screw feeder, a mixing vessel, a rotary vacuum-filter, and a feeder with a bulk storage vessel.

[0088] The off-gas from the granulator of the urea production plant is mixed with a sorbent comprising water. To separate the sorbent from the air stream, baghouse filters are used. Here, all of the particulate urea is removed cocurrently with most of the ammonia in the gas phase. The former is removed by filtration and the latter is adsorbed on the adsorbent.

[0089] Ammonia adsorption is accomplished through a filter cake of adsorbent on the bag. Ammonia adsorption is similar to processes using fixed beds as the gas passes through the filter cake. The design goal is to remove greater than 90% of ammonia and greater than 99.95% of particulate urea. Because urea dust is removed in the baghouse filter, currently used scrubbers can be r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| surface area | aaaaa | aaaaa |

| surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com