A kind of preparation method of easy decontamination jacquard fabric

A technology for easy decontamination and fabrics, applied in the direction of anti-coloring pollution/anti-fouling fibers, textiles and papermaking, fiber processing, etc. , good stability, excellent water repellency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A kind of preparation method of easy decontamination jacquard fabric, concrete steps are:

[0031] (1) Mix 2g of methyltrimethoxysilane, 0.19g (0.8CMC) sodium lauryl sulfate and 100g of water, stir vigorously at 25°C for 1h, slowly add 3mL of ammonia water with a catalyst mass concentration of 15% , stirred for 3h, then added 2g of dodecyltrimethoxysilane, and continued to stir for 3h to obtain modified SiO 2 Hydrosol;

[0032] (2) Preparation of finishing solution: take modified SiO 2 4g of hydrosol, 2g of hydrophilic component (obtained by mixing acrylic acid and glycerol in a molar ratio of 3:1) and 94g of water were mixed and vigorously stirred to obtain a finishing solution;

[0033] (3) The jacquard fabric is finished in the above-mentioned finishing solution according to the two-dipping and two-rolling process (residual rate of 70%), dried at 80°C for 2.5min, and then baked at 160°C for 1min to obtain the treated easy Stain release jacquard fabric.

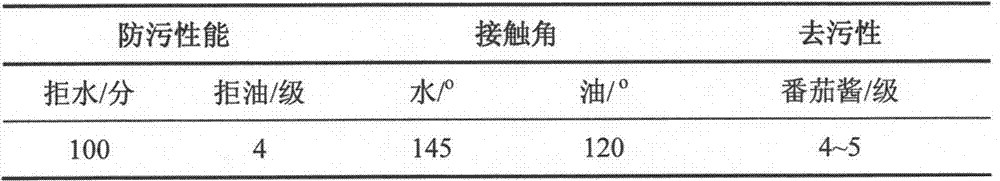

[0034] The...

Embodiment 2

[0042] A kind of preparation method of easy decontamination jacquard fabric, concrete steps are:

[0043] (1) Mix 3g tetramethoxysilane, 0.38g (1.0CMC) sodium dodecylsulfonate and 100g water, stir vigorously at 40°C for 1h, slowly add 2mL of ammonia water with a catalyst mass concentration of 15% , stirred for 4h, then added 2g of hexadecyltrimethoxysilane, and continued to stir for 5h to obtain modified SiO 2 Hydrosol.

[0044] (2) Preparation of finishing solution: take modified SiO 2 Mix 3.5g of hydrosol, 3g of hydrophilic component (obtained by mixing methacrylic acid and propylene glycol at a molar ratio of 2:1) and 92g of water, and stir vigorously to obtain a finishing solution;

[0045] (3) The jacquard fabric is finished in the above-mentioned finishing solution according to the two-dipping and two-rolling process (the excess rate is 80%), dried at 80°C for 3min, and then baked at 150°C for 1.5min to obtain the treated easy-to-treat fabric. Stain release jacquard f...

Embodiment 3

[0050] A kind of preparation method of easy decontamination jacquard fabric, concrete steps are:

[0051] (1) Mix 3g tetramethoxysilane, 0.38g (1.0CMC) sodium dodecylsulfonate and 100g water, stir vigorously at 40°C for 1h, slowly add 2mL of ammonia water with a catalyst mass concentration of 15% , stirred for 4h, then added 2g of hexadecyltrimethoxysilane, and continued to stir for 5h to obtain modified SiO 2 Hydrosol.

[0052] (2) Preparation of finishing solution: take modified SiO 2 Mix 4g of hydrosol, 2g of hydrophilic component (obtained by mixing hydroxyacrylic acid and triethanolamine in a molar ratio of 3:2) and 94g of water, and stir vigorously to obtain a finishing solution;

[0053] (3) The jacquard fabric is finished in the above-mentioned finishing liquid according to the two-dipping and two-rolling process (the excess rate is 75%), dried at 80°C for 2min, and then baked at 170°C for 1min to obtain a treated easy-to-remove fabric. Dirty jacquard fabric.

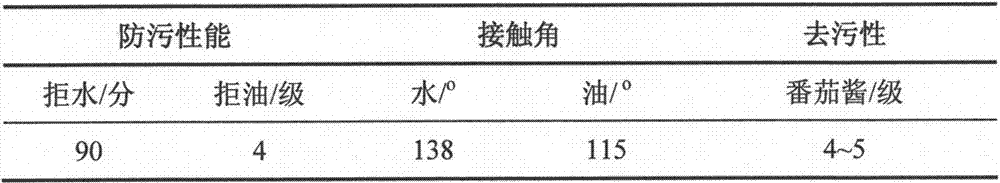

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com