Waterborne three-component polyester paint and preparation method thereof

A three-component, polyester paint technology, used in polyester coatings, coatings, etc., can solve problems such as human poisoning, isocyanate side reactions, affecting curing efficiency, etc., to reduce damage or pollution, enhance yellowing resistance, The effect of increasing the drying rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

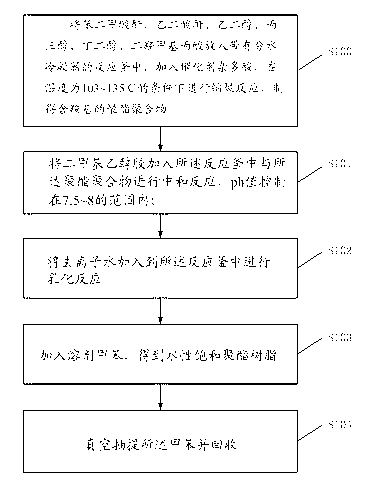

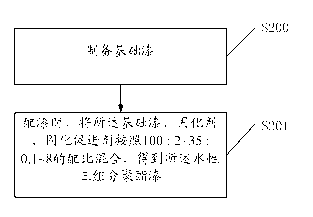

[0094] Such as figure 2 Shown, the preparation method of described waterborne three-component polyester paint may further comprise the steps:

[0095] S200, preparing a base paint.

[0096] Wherein, preparation base paint comprises:

[0097] Add the 0.1~6% wetting agent, 0.1~8% leveling agent, 10~60% diluent and 0.01~35% pigments and fillers into the dispersing tank, start the dispersing machine, mix for 10~60min, and obtain the first mixture.

[0098] Preferably, add the 0.2~5% wetting agent, 0.5~6% leveling agent, 10~50% diluent and 0.01~30% pigments and fillers into the dispersion tank, start the disperser, mix for 10~60min, A first mixture is obtained.

[0099] Add the 20-55% skeleton agent into the dispersion tank, stir and mix with the first mixture for 10-60min to obtain the second mixture.

[0100] Preferably, the 25-55% matrix agent is added into the dispersion tank, and stirred and mixed with the first mixture for 10-60 minutes to obtain the second mixture.

...

Embodiment 1

[0110] Add 0.1% wetting agent, 0.1% leveling agent, 20% diluent and 10% pigments and fillers into the dispersing tank, start the dispersing machine, and mix for 10-60 minutes to obtain the first mixture; add the 25% framework agent In the dispersing tank, stir and mix with the first mixture for 10~60min, obtain the second mixture; Described 0.5% defoamer, 0.01% thickener, 0.01% pH value regulator are added in the dispersing tank, and the second The mixture was stirred and mixed for 10~60min to obtain the third mixture; the third mixture was cooled and filtered to obtain the base paint; The proportioning mixes, obtains described water-based three-component polyester paint.

Embodiment 2

[0112] Add 6% wetting agent, 8% leveling agent, 60% diluent and 35% pigments and fillers into the dispersing tank, start the dispersing machine, and mix for 10-60 minutes to obtain the first mixture; add the 55% framework agent In the dispersing tank, stir and mix with the first mixture for 10 ~ 60min to obtain the second mixture; the 8% defoamer, 8% thickener, and 2% pH value regulator are added to the dispersing tank, and mixed with the second The mixture was stirred and mixed for 10~60min to obtain the third mixture; the third mixture was cooled and filtered to obtain the base paint; The proportioning mixes, obtains described water-based three-component polyester paint.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com