Waterborne polyurethane ultraviolet curing coating and preparation method thereof

A technology of water-based polyurethane and curing coatings, applied in the field of coatings, can solve the problems of low solid content of water-based coatings, easy high-temperature back-sticking, high viscosity, etc., and achieve good low-temperature film-forming properties, simple construction, and good filling properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

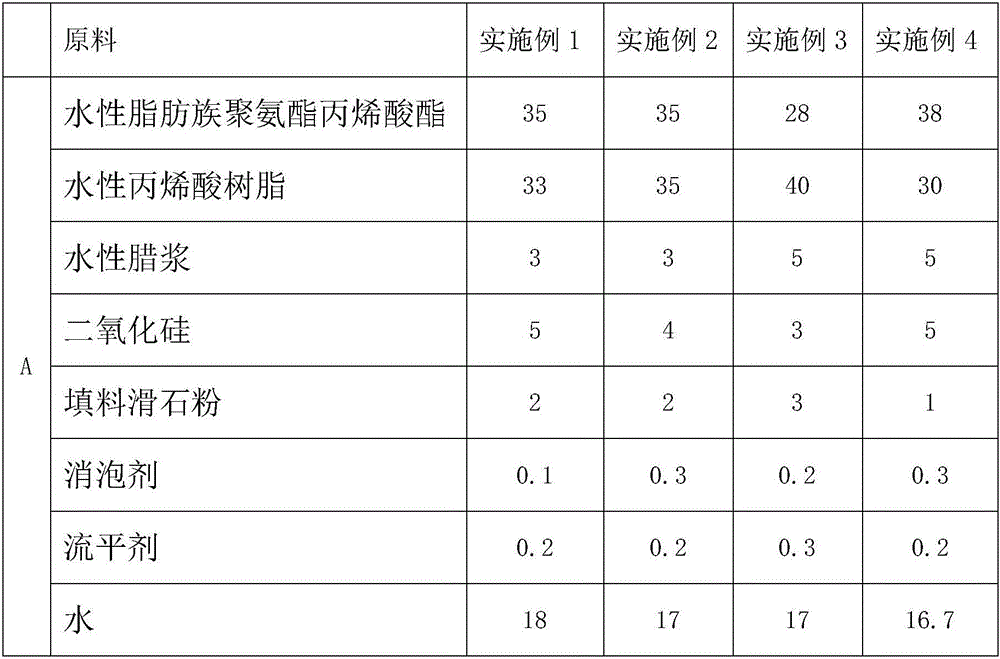

[0029] The present invention will be further described below in conjunction with specific embodiment:

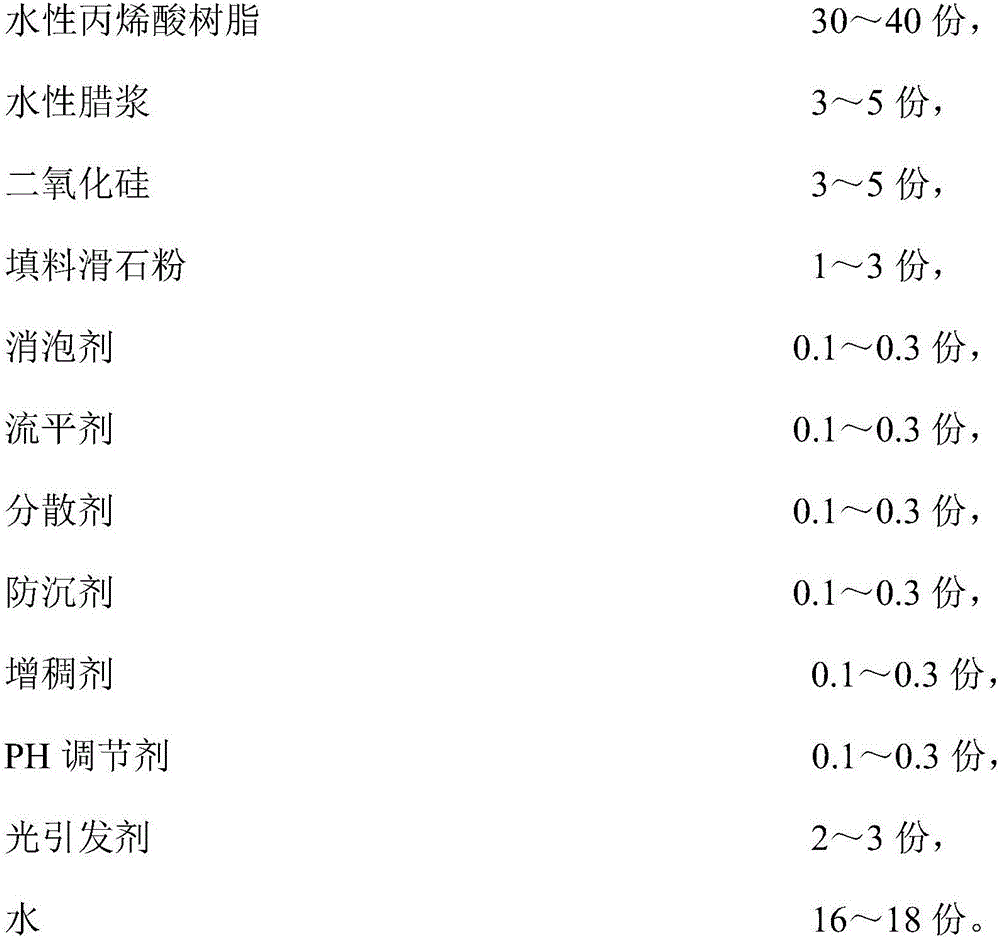

[0030] A kind of water-based polyurethane UV-curable coating, by weight component, its formula consists of:

[0031]

[0032]

[0033] In the above-mentioned embodiment 1, the water-based wax slurry is oxidized polyethylene wax, the dispersant is obtained by compounding polyethylene glycol and propylene glycol methyl ether, the thickener is polyoxypropylene glycol, and the photoinitiator is phenyldimethyl Benzoyl oxophosphorus.

[0034] In the above-mentioned embodiment 2, the water-based wax paste is modified polyethylene wax, the dispersant is obtained by compounding triethanolamine and propylene glycol methyl ether, the thickener is polyoxypropylene triol, and the photoinitiator is phenyltrimethylbenzene Formyl oxophosphorus.

[0035] In the above-mentioned embodiment 3, the water-based wax paste is polytetrafluoroethylene wax, the dispersant is obtained by compou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com