Emulsion with core-shell structure and environment-friendly interior wall coating containing emulsion

A core-shell structure and interior wall coating technology, which is applied to biocide-containing paints, antifouling/underwater coatings, coatings, etc., can solve the problem of not balancing environmental protection and usability, stain resistance, and Reduced scrubability, increased VOC content, etc., to achieve excellent stain resistance, excellent scrub resistance, and improved conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0068] The preparation method of above-mentioned core-shell structure emulsion comprises the following steps:

[0069] 1) Preparation of pre-emulsion: add emulsifier and sodium polyacrylate into water, mix uniformly, then add mixed monomer 1, mix uniformly, fully emulsify, and obtain pre-emulsion;

[0070]2) Seed polymerization: adding a part of the initiator and the mixed monomer 2 into the pre-emulsion to carry out a polymerization reaction to obtain a seed emulsion;

[0071] 3) Emulsion polymerization: adding the remaining initiator and mixed monomer 3 into the seed emulsion to carry out a polymerization reaction, and then adding a pH buffer to adjust the pH value of the reaction solution to obtain a core-shell structure emulsion;

[0072] The mixed monomer 1 is composed of methyl methacrylate, styrene, butyl acrylate and methacrylic acid, and n 甲基丙烯酸甲酯 +n 苯乙烯 丙烯酸丁酯 +n 甲基丙烯酸 (that is, the total substance amount of methyl methacrylate and styrene is less than the total su...

Embodiment 1

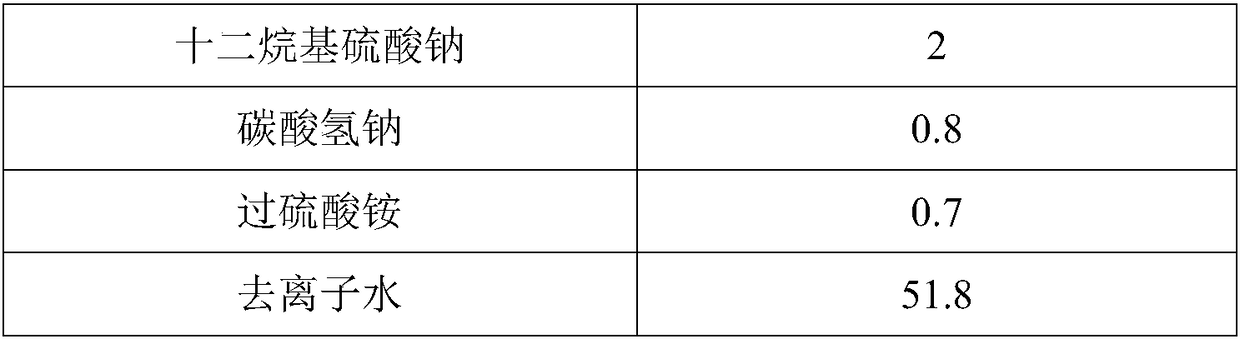

[0095] A kind of core-shell structure emulsion, its raw material composition is as shown in the following table:

[0096] The raw material composition table of a kind of core-shell structure emulsion of table 1

[0097]

[0098]

[0099] The preparation method of above-mentioned core-shell structure emulsion comprises the following steps:

[0100] 1) Preparation of pre-emulsion: Add polyoxyethylene alkylphenyl ether, sodium lauryl sulfate and sodium polyacrylate into deionized water, mix well, then add mixed monomer 1 (containing 6 parts of methyl methacrylate ester, 2 parts of styrene, 7 parts of butyl acrylate and 4 parts of methacrylic acid), heated to 80°C, stirred and emulsified for 0.5h to obtain a pre-emulsion;

[0101] 2) Seed polymerization: Add 0.4 parts of ammonium persulfate and mixed monomer 2 (containing 3 parts of hydroxypropyl acrylate) dropwise to the pre-emulsion, and after 1 hour, the dropwise addition is completed, and then polymerized at 80°C for 2 ...

Embodiment 2

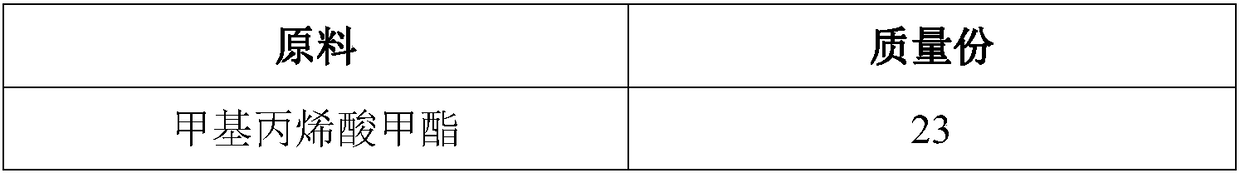

[0104] A kind of core-shell structure emulsion, its raw material composition is as shown in the following table:

[0105] The raw material composition table of a kind of core-shell structure emulsion of table 2

[0106] raw material

parts by mass

18

8

10

4

3

Sodium polyacrylate

1.5

Polyoxyethylene alkylphenyl ether

0.8

2

0.5

0.5

Deionized water

51.7

[0107] The preparation method of above-mentioned core-shell structure emulsion comprises the following steps:

[0108] 1) Preparation of pre-emulsion: Add polyoxyethylene alkylphenyl ether, sodium lauryl sulfate and sodium polyacrylate into deionized water, mix well, then add mixed monomer 1 (containing 6 parts of methyl methacrylate ester, 3 parts of styrene, 7 parts of b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com