Double-liquid polyurethane coating

A technology of liquid polyurethane and coatings, applied in the field of coatings, can solve the problems of coating film gloss, hardness, poor fullness, poor adhesion of plastic materials, etc., and achieve the effect of excellent wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

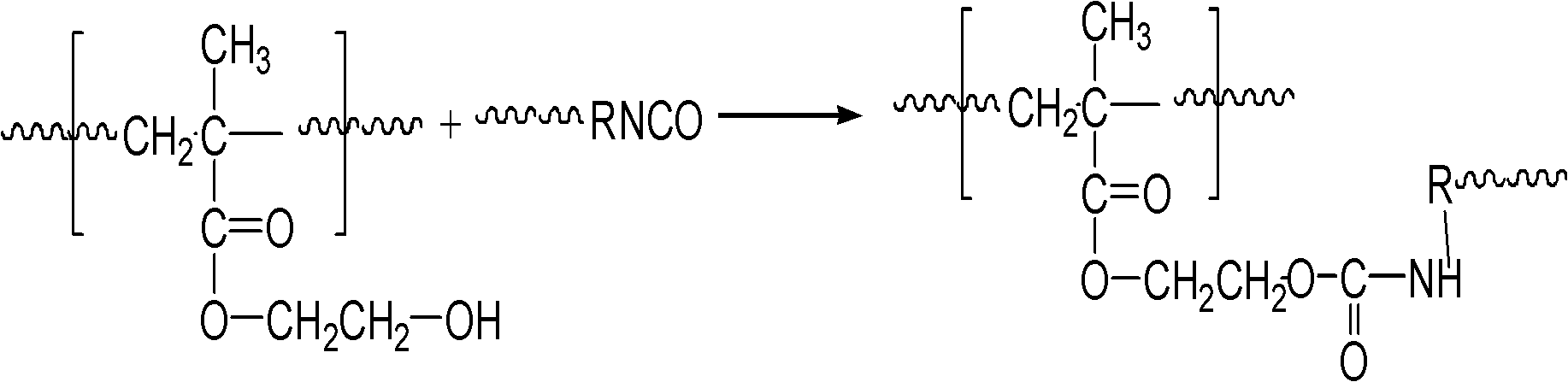

Method used

Image

Examples

Embodiment 1

[0020] A two-component polyurethane coating, suitable for water transfer printing surface coating of automobile interior, is composed of A component and B component, and the mass ratio of A component and B component is 4: 1; Sub-composition includes composition and the mass percent of each composition as follows:

[0021] High hydroxyl acrylic resin 38%;

[0022] Low hydroxyl acrylic resin 15%;

[0023] Xylene or propylene glycol methyl ether acetate 45%;

[0024] Polyether modified polydimethylsiloxane copolymer 1%;

[0025] UV absorber 1%;

[0026] The B component is an aliphatic polyisocyanate curing agent.

[0027] The aliphatic polyisocyanate curing agent is selected from Bayer N3390 curing agent.

[0028] The ultraviolet absorber is selected from salicylate ultraviolet absorbers.

[0029] The ultraviolet absorber is selected from salicylphenyl ester.

[0030] The A component and the B component can be mixed uniformly before use.

Embodiment 2

[0032] A two-component polyurethane coating, suitable for water transfer printing surface coating of automobile interior, is composed of A component and B component, and the mass ratio of A component and B component is 4.5:1; Sub-composition includes composition and the mass percent of each composition as follows:

[0033] High hydroxyl acrylic resin 55%;

[0034] Low hydroxyl acrylic resin 10%;

[0035] Xylene or propylene glycol methyl ether acetate 34%;

[0036] Polyether modified polydimethylsiloxane copolymer 0.5%;

[0037] UV absorber 0.5%;

[0038] The B component is an aliphatic polyisocyanate curing agent.

[0039] The aliphatic polyisocyanate curing agent is selected from Bayer bayer Desmodos N3300 aliphatic polyisocyanate (HDI trimer) curing agent.

[0040] The ultraviolet absorber is selected from benzophenones, benzotriazoles, substituted acrylonitriles and triazine ultraviolet absorbers.

[0041] The ultraviolet absorber is selected from ultraviolet absor...

Embodiment 3

[0044] A two-component polyurethane coating, suitable for water transfer printing surface coating of automobile interior, is composed of A component and B component, and the mass ratio of A component and B component is 4: 1; Sub-composition includes composition and the mass percent of each composition as follows:

[0045] High hydroxyl acrylic resin 46%;

[0046] Low hydroxyl acrylic resin 12%;

[0047] Xylene or propylene glycol methyl ether acetate 40%;

[0048] Polyether modified polydimethylsiloxane copolymer 1%;

[0049] UV absorber 1%;

[0050] The B component is an aliphatic polyisocyanate curing agent.

[0051] The aliphatic polyisocyanate curing agent is selected from Bayer N3390 curing agent.

[0052] The ultraviolet absorber is selected from water benzotriazole ultraviolet absorbers.

[0053] The A component and the B component can be mixed uniformly before use.

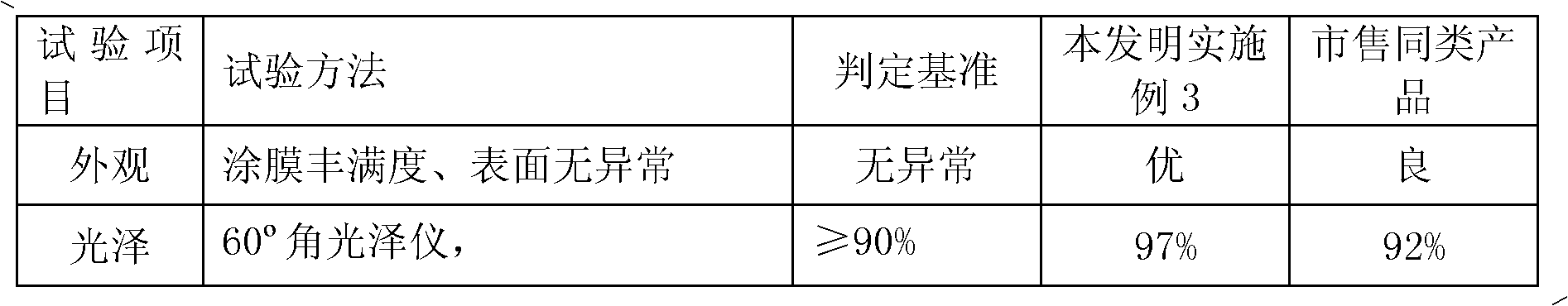

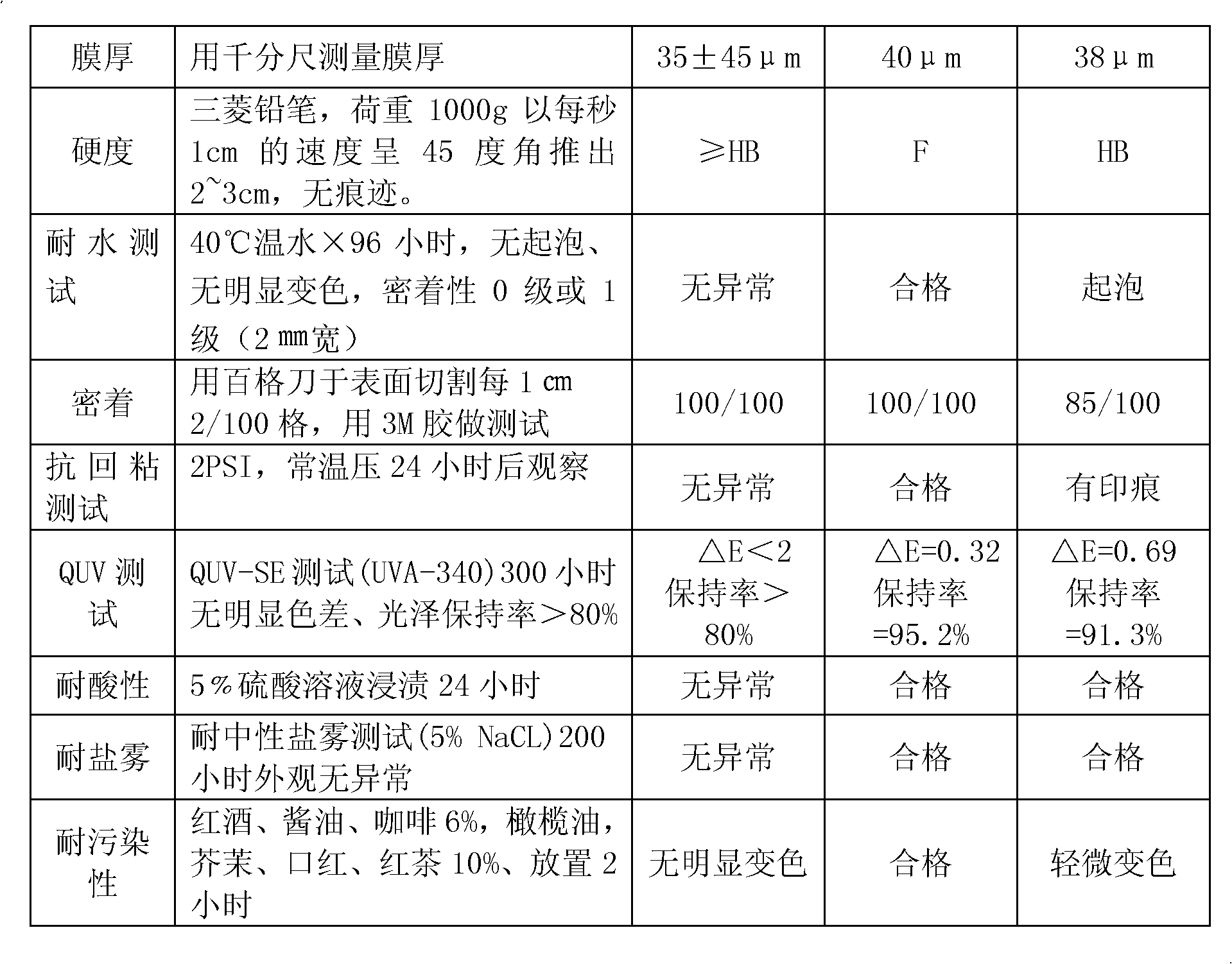

[0054] In order to further illustrate the performance of the two-component polyurethane coating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com