Base material coloring agent and preparation method thereof

A technology of color wiper and base material, which is applied in the direction of biocide-containing paint, coating, antifouling/underwater coating, etc., which can solve the problems of untested adhesion and achieve excellent adhesion, good water resistance, excellent The effect of adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

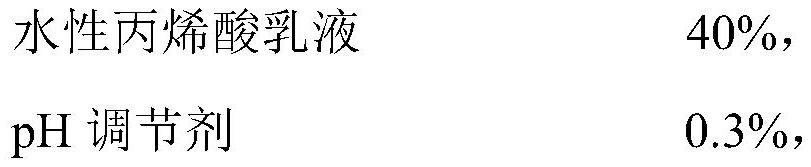

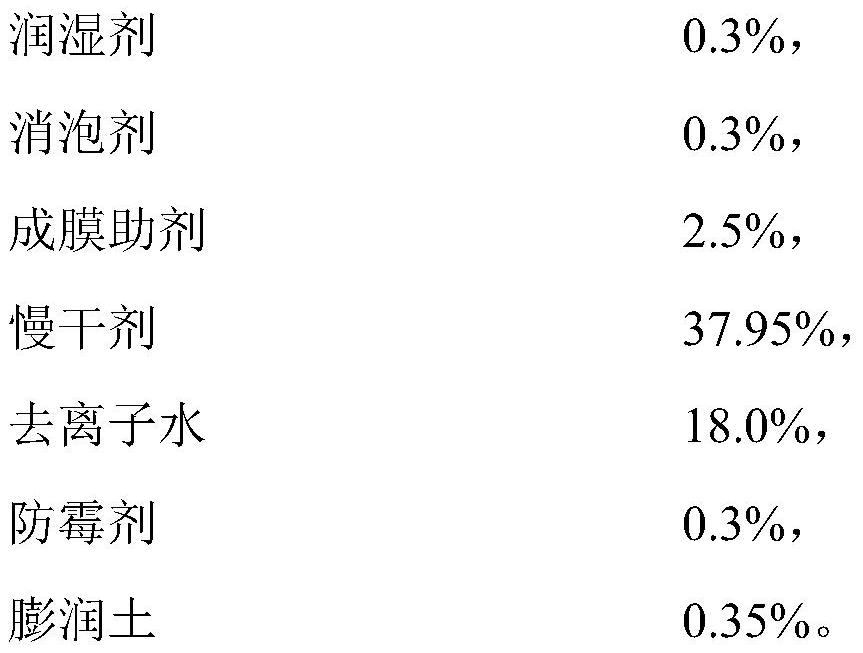

[0053] The preparation method of the above main components is as follows:

[0054] S1. Put water-based acrylic emulsion into the paint making tank, then put in pH regulator under the condition of stirring, disperse at a speed of 600-800r / min, and adjust the pH value to 8-9;

[0055] S2. Add wetting agent and defoamer in turn, and disperse for 5 minutes at a speed of 800-1000r / min;

[0056] S3. Mix the film-forming aid, slow-drying agent and deionized water evenly in advance, and slowly put them into the paint-making tank under stirring conditions;

[0057] S4. Finally, slowly put the antifungal agent and bentonite into the paint tank one by one, stir at a speed of 1000-1200r / min for 20 minutes until completely mixed, filter and pack.

Embodiment 1

[0059] Mix the main component-A with the supporting color paste according to the ratio of 100:20, and adjust to a suitable construction viscosity to obtain the substrate color wiper of Example 1.

Embodiment 2

[0061] Mix the main component-B with the matching color paste at a ratio of 100:15, and adjust to a suitable construction viscosity to obtain the base material color wiper of Example 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| minimum film forming temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com