Inorganic polymer exterior wall coating as well as preparation method and application thereof

A technology of inorganic polymers and exterior wall coatings, applied in anti-corrosion coatings, anti-fouling/underwater coatings, coatings, etc., can solve the problems of poor acid and alkali resistance, poor water resistance, low adhesion, etc., and achieve scrub resistance Excellent, strong weather resistance, excellent water resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

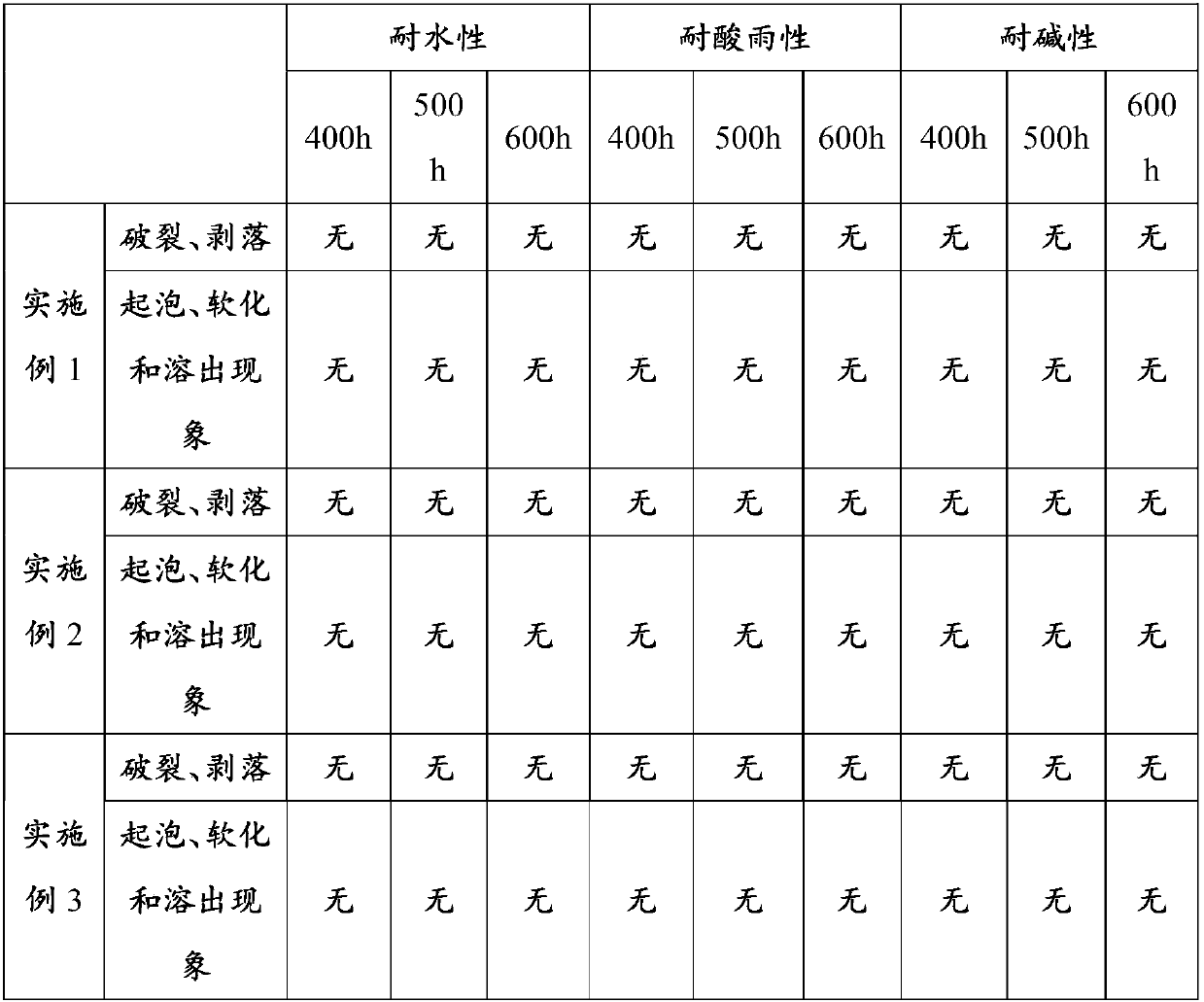

Embodiment 1

[0028] An inorganic polymer exterior wall paint, the raw materials of the inorganic macromolecule exterior wall paint are proportioned in parts by mass: 16 parts of water, 1 part of waterproofing agent, 0.2 part of wetting and dispersing agent, 0.3 part of defoaming agent, bactericidal 0.6 parts of agent, 2 parts of 800 mesh light calcium carbonate, 0.3 parts of AMP-95, 13 parts of barium sulfate, 11 parts of rutile titanium dioxide, 0.1 part of color paste, 9 parts of talcum powder, 12 parts of 4000 mesh calcined kaolin, benzene 6 parts of acrylic emulsion, 12 parts of potassium silicate, 3 parts of glycol, 1 part of emulsified OP-10, 0.1 part of water glass, 0.3 part of film-forming aid, 0.6 part of polyvinyl alcohol, 15 parts of hydroxyethyl cellulose , 0.2 parts of lime calcium powder, 0.3 parts of mica powder, 6 parts of quartz powder, 0.5 parts of vanadium pentoxide, 1 part of calcium fluoride, 3 parts of zinc phosphate, 1 part of aluminum silicate, 0.2 parts of calcium p...

Embodiment 2

[0037] An inorganic polymer exterior wall paint, the raw materials of the inorganic polymer exterior wall paint are proportioned by mass: 20 parts of water, 3 parts of waterproofing agent, 0.6 part of wetting and dispersing agent, 0.5 part of defoaming agent, bactericidal 0.6 parts of agent, 4 parts of 800 mesh light calcium carbonate, 0.5 parts of AMP-95, 15 parts of barium sulfate, 13 parts of rutile titanium dioxide, 0.3 parts of color paste, 11 parts of talcum powder, 13 parts of 4000 mesh calcined kaolin, benzene 8 parts of acrylic emulsion, 16 parts of potassium silicate, 5 parts of glycol, 3 parts of emulsified OP-10, 1 part of water glass, 0.5 parts of film-forming aid, 1 part of polyvinyl alcohol, 17 parts of hydroxyethyl cellulose , 0.6 parts of lime calcium powder, 0.5 parts of mica powder, 10 parts of quartz powder, 1.5 parts of vanadium pentoxide, 3 parts of calcium fluoride, 5 parts of zinc phosphate, 2 parts of aluminum silicate, 0.4 parts of calcium pyrophosphat...

Embodiment 3

[0046] An inorganic polymer exterior wall paint, the raw materials of the inorganic polymer exterior wall paint are proportioned by mass: 18 parts of water, 2 parts of waterproofing agent, 0.4 part of wetting and dispersing agent, 0.4 part of defoaming agent, bactericidal 0.6 parts of agent, 3 parts of 800 mesh light calcium carbonate, 0.4 parts of AMP-95, 14 parts of barium sulfate, 12 parts of rutile titanium dioxide, 0.2 parts of color paste, 10 parts of talcum powder, 12.5 parts of 4000 mesh calcined kaolin, benzene 7 parts of acrylic emulsion, 14 parts of potassium silicate, 4 parts of glycol, 2 parts of emulsified OP-10, 0.5 parts of water glass, 0.4 parts of film-forming aid, 0.8 parts of polyvinyl alcohol, 16 parts of hydroxyethyl cellulose , 0.4 parts of lime calcium powder, 0.4 parts of mica powder, 8 parts of quartz powder, 1 part of vanadium pentoxide, 2 parts of calcium fluoride, 4 parts of zinc phosphate, 1.5 parts of aluminum silicate, 0.3 parts of calcium pyroph...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com