Epoxy resin modified waterborne acrylic resin dispersion

A water-based acrylic and acrylic resin technology, which is applied in coatings, anti-corrosion coatings, etc., can solve the problems of performance degradation, resin gelation and performance degradation, hidden dangers of storage stability, etc., and achieve excellent salt spray resistance, weather resistance and gloss retention Good, low-temperature film-forming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

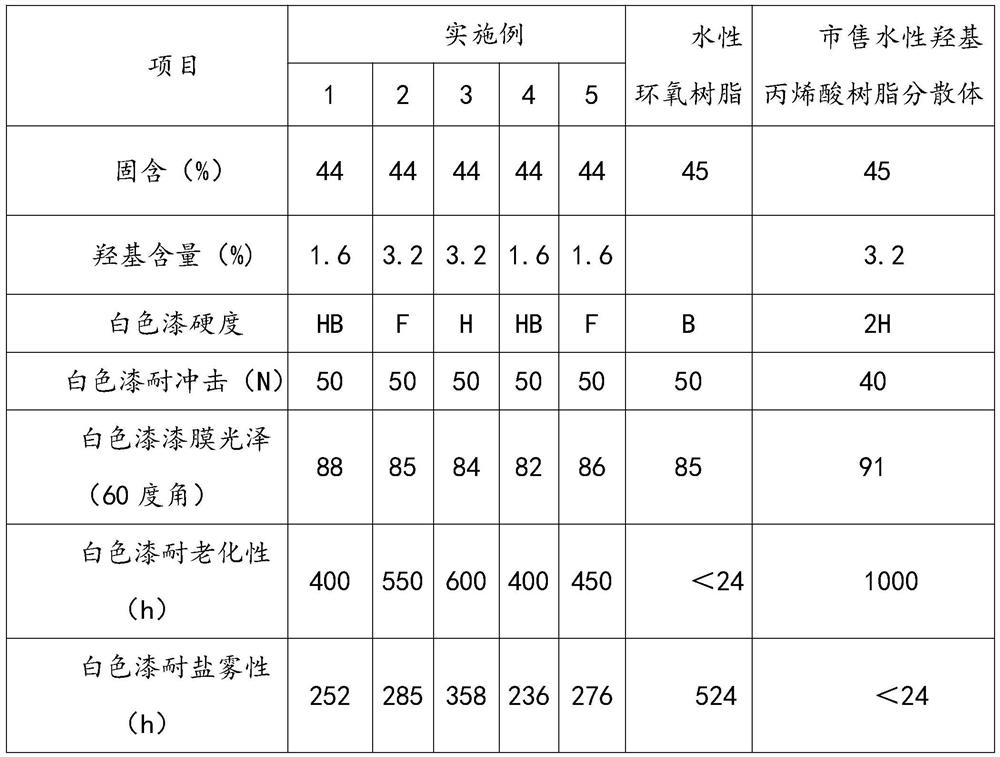

Examples

preparation example Construction

[0041] The preparation of the dispersion selects any of the following three preparation methods:

[0042] Preparation method 1: make a primer with epoxy resin and organic solvent, add acrylate monomers step by step, keep warm, neutralize, and then add water to disperse;

[0043] Preparation method 2: After acrylic resin is synthesized by adding acrylate monomers dropwise into an organic solvent, epoxy resin is added in the middle, after high-speed mixing, add water to disperse;

[0044] Preparation method three: after the acrylic resin is synthesized in the acrylic resin monomer, epoxy resin is added after adding water to disperse;

[0045] In general, method 1 and method 2 are preferred.

Embodiment 1

[0047] Add 100g of epoxy resin E51, 100g of No. 100 solvent naphtha, and 100g of ethylene glycol butyl ether into the reaction bottle and stir to raise the temperature to 140-148°C. At the same time, pass nitrogen gas to exhaust the air in the bottle. Keep the temperature range and prepare to add acrylic acid mono bodies and initiators;

[0048] Mix 350g of methyl methacrylate, 250g of styrene, 550g of butyl methacrylate, and 125g of hydroxyethyl methacrylate into the dropping funnel;

[0049] Mix 25g of t-amyl peroxide, 25g of No. 100 solvent naphtha, and 25g of ethylene glycol butyl ether, and pack it with another dropping funnel; first, add 1 / 5 of the initiator mixture to the bottle,

[0050] After that, the monomer and the initiator funnel start to add materials dropwise at the same time, and the drops are completed synchronously after 4-5 hours;

[0051] Then add 5g of t-amyl peroxide and keep warm for one hour;

[0052] Then 125g of methyl methacrylate, 150g of monomet...

Embodiment 2

[0060] Add 120g of epoxy resin E511, 150g of No. 100 solvent oil, and 100g of ethylene glycol butyl ether into the reaction bottle, stir and raise the temperature to 130-140°C, and at the same time, pass nitrogen gas to exhaust the air in the bottle, keep the temperature range, and prepare to add acrylic acid mono bodies and initiators;

[0061] Mix 300g of methyl methacrylate, 200g of styrene, 530g of butyl methacrylate, 2g of acrylic acid, and 350g of hydroxyethyl methacrylate into the dropping funnel;

[0062] Mix 35g of t-amyl peroxide and 25g of ethylene glycol butyl ether evenly, and install it with another dropping funnel; first add one-fifth of the initiator mixture to the bottle, and then the monomer and the initiator funnel At the same time, start to add the material dropwise, after 4-5 hours, the dripping is completed synchronously, and then add 5g of t-amyl peroxide, and keep warm for one hour;

[0063] Then 50 g of methyl methacrylate, 150 g of polyethylene glyco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| gloss | aaaaa | aaaaa |

| gloss | aaaaa | aaaaa |

| gloss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com