Water-borne acrylic polyurethane primer-topcoat corrosion-resistant decorative coating containing double components and preparation method of coating

An acrylic polyurethane and decorative paint technology, applied in the field of coatings, can solve the problems of excessive lead content of anti-rust pigments, weather resistance, poor decorative properties, and general chemical resistance of resins, achieving low VOC, good mechanical properties, and reducing environmental pollution. effect of cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

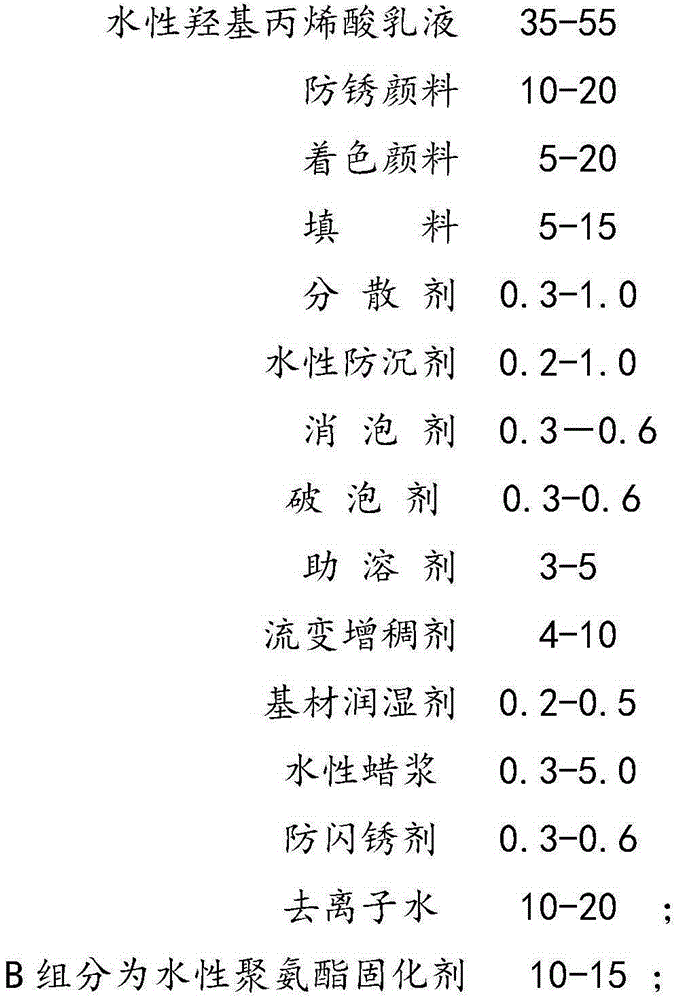

[0019] A kind of two-component water-based acrylic polyurethane bottom surface all-in-one anticorrosion decorative paint, it is made up of A, B two components, and described A component comprises following component, by weight g,

[0020] Water-based hydroxyl acrylic emulsion 35g, anti-rust pigment 10g, coloring pigment 5g, filler 5g dispersant 0.3g, water-based anti-settling agent 0.2g, defoamer 0.3g, foam breaker 0.3g, co-solvent 3g rheological thickener 4g , Substrate wetting agent 0.2g, water-based wax slurry 0.3g, anti-flash rust agent 0.3g, deionized water 10g;

[0021] The B component is 10 g of water-based polyurethane curing agent.

[0022] The preparation method of above-mentioned two-component water-based acrylic polyurethane bottom surface all-in-one anticorrosion decorative paint is carried out according to the following steps,

[0023] One, the preparation of A component: by weight parts,

[0024] ① Add 1 / 2 of the formula amount of water-based hydroxyacrylic em...

Embodiment 2

[0030] A kind of two-component water-based acrylic polyurethane bottom surface all-in-one anticorrosion decorative paint, it is made up of A, B two components, and described A component comprises following component, by weight g,

[0031] Water-based hydroxyl acrylic emulsion 55g, anti-rust pigment 20g, coloring pigment 20g, filler 15g dispersant 1.0g, water-based anti-settling agent 1.0g, defoamer 0.6g, foam breaker 0.6g, co-solvent 5g rheological thickener 10g , Substrate wetting agent 0.5g, water-based wax slurry 5.0g, anti-flash rust agent 0.6g, deionized water 20g;

[0032] The B component is 15g of water-based polyurethane curing agent.

[0033] The preparation method of the above-mentioned two-component water-based acrylic polyurethane bottom surface integrated anti-corrosion decorative paint is prepared according to the method of Example 1.

Embodiment 3

[0035] A kind of two-component water-based acrylic polyurethane bottom surface all-in-one anticorrosion decorative paint, it is made up of A, B two components, and described A component comprises following component, by weight g,

[0036] Water-based hydroxyl acrylic emulsion 40g, anti-rust pigment 15g, coloring pigment 10g, filler 10g dispersant 0.5g, water-based anti-settling agent 0.5g, defoamer 0.4g, foam breaker 0.4g, co-solvent 4g rheological thickener 8g , Substrate wetting agent 0.3g, water-based wax slurry 2g, anti-flash rust agent 0.4g, deionized water 15g;

[0037] The B component is 12g of water-based polyurethane curing agent.

[0038] The preparation method of the above-mentioned two-component water-based acrylic polyurethane bottom surface integrated anti-corrosion decorative paint is prepared according to the method of Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com