Normal-temperature curing high-hardness steel bar anticorrosive coating and preparation method thereof

A kind of anti-corrosion coating, curing technology at room temperature, applied in the direction of anti-corrosion coating, anti-fouling/underwater coating, alkali metal silicate coating, etc., can solve the problems of human body harm, pollution of natural environment, etc., and achieve good moldability and preparation technology Simple, excellent effect of non-combustibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

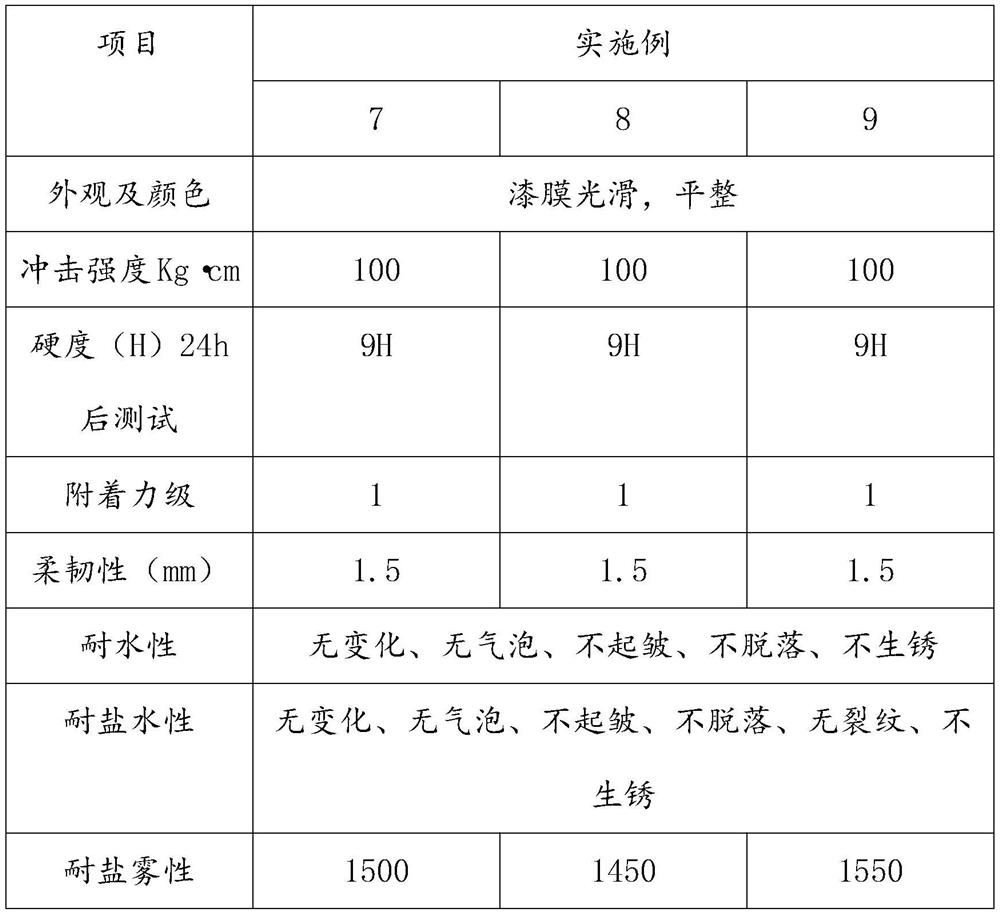

Embodiment 1

[0034] An anticorrosion coating for steel bars cured at room temperature with high hardness, comprising the following components in parts by weight: a solid component, a liquid component, and a styrene-acrylic emulsion; the weight ratio of the solid component to the liquid component is 1:0.9;

[0035] The solid components include: kaolin: 80 parts; slag: 5 parts; cement: 3 parts; latex powder 2.5 parts;

[0036] The liquid components include: sodium silicate: 80 parts; defoamer: 0.2 parts; adhesive agent: 1.2 parts; styrene-acrylic emulsion: 15 parts.

[0037] The kaolin is 1250 mesh kaolin powder produced by Lingshou Suda Mineral Products Co., Ltd., Lingshou County, Hebei Province, and its Al:Si=1.04.

[0038] The slag is S105 slag produced by Shijiazhuang Runchuan Building Materials Co., Ltd.

[0039] Described cement is Conch brand Po42.5 cement.

[0040] Described latex powder is Germany Wacker brand latex powder 5044N.

Embodiment 2

[0056]An anticorrosion coating for steel bars cured at room temperature with high hardness, comprising the following components in parts by weight: a solid component, a liquid component, and a styrene-acrylic emulsion; the weight ratio of the solid component to the liquid component is 1:0.95;

[0057] The solid components include: kaolin: 90 parts; slag: 8 parts; cement: 2.5 parts; latex powder 2.5 parts;

[0058] The liquid components include: sodium silicate: 90 parts; defoamer: 1 part; adhesive agent: 2.5 parts; styrene-acrylic emulsion: 20 parts.

[0059] The kaolin is 1250 mesh kaolin powder, and its Al:Si=1.04. The slag is S105 slag. Described cement is Po42.5 cement. The latex powder complained is rubber powder 5044N.

[0060] The defoamer is a silicone defoamer. The adhesive is silica sol LUDOX HS-40. Described sodium water glass is water glass.

[0061] Described water glass, the step of preparation method is:

[0062] Step 1) configuration mass fraction is 40%...

Embodiment 3

[0067] An anticorrosion coating for steel bars cured at room temperature with high hardness, comprising the following components in parts by weight: a solid component, a liquid component, and a styrene-acrylic emulsion; the weight ratio of the solid component to the liquid component is 1:1.0;

[0068] The solid components include: kaolin: 100 parts; slag: 10 parts; cement: 5 parts; latex powder 5 parts;

[0069] The liquid components include: sodium silicate: 100 parts; defoamer: 2 parts; adhesive agent: 5 parts; styrene-acrylic emulsion: 25 parts.

[0070] The kaolin is 1250 mesh kaolin powder, and its Al:Si=1.04. The slag is S105 slag. Described cement is Po42.5 cement. The latex powder complained is rubber powder 5044N.

[0071] The defoamer is a silicone defoamer. The adhesive is silica sol LUDOX HS-40. Described sodium water glass is water glass.

[0072] Described water glass, the step of preparation method is:

[0073] Step 1) configuration mass fraction is 40% s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com