Skid-resistant coating and preparation method thereof

An anti-skid coating and anti-skid technology, applied in the coating field, can solve the problems of falling off of anti-skid particles, limited service life of anti-skid coating, damage to the stability of the coating, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

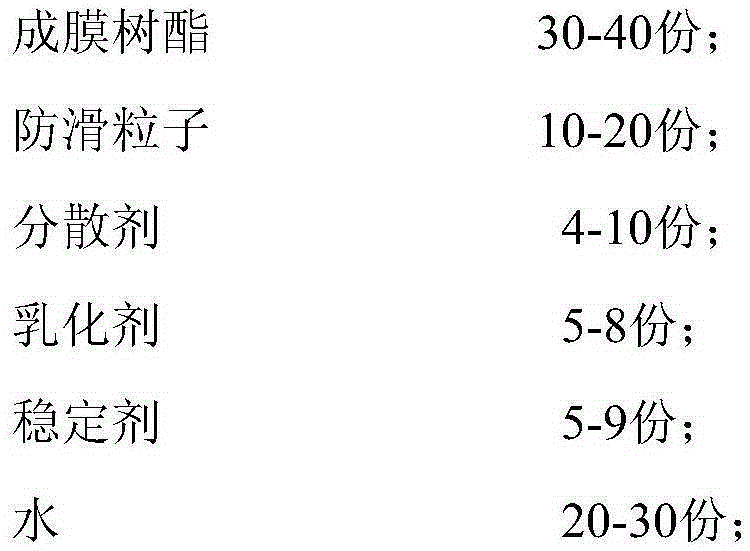

[0033] Embodiment 1 A kind of antiskid coating, is made up of the component of following parts, and described parts are weight parts:

[0034]

[0035] The preparation technology of antiskid coating of the present invention is as follows:

[0036] (1) Add the above components into the mixing tank, stir and mix at room temperature at a shear rate of 2000r / min for 1 hour, and then ultrasonically disperse for 3 hours.

[0037] (2) Grinding and filtering the above components to remove mechanical impurities.

[0038] (3) Add curing agent 40 minutes before construction, and construction can be carried out.

Embodiment 2

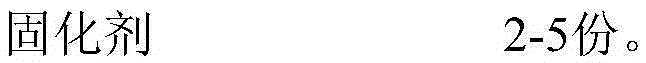

[0039] Embodiment 2 A kind of anti-slip coating, is made up of the component of following parts, and described parts are weight parts:

[0040]

[0041]

[0042] The preparation technology of antiskid coating of the present invention is as follows:

[0043] (1) Add the above components into the mixing tank, stir and mix at room temperature at a shear rate of 2500r / min for 2 hours, and then ultrasonically disperse for 2 hours.

[0044] (2) Grinding and filtering the above components to remove mechanical impurities.

[0045] (3) Add the curing agent 335 minutes before the construction, and the construction can be carried out.

Embodiment 3

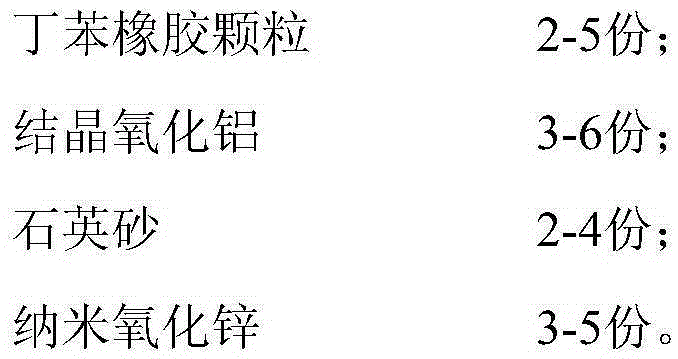

[0046] Embodiment 3 A kind of non-slip coating, is made up of the component of following parts, and described parts are weight parts:

[0047]

[0048] The preparation technology of antiskid coating of the present invention is as follows:

[0049] (1) Put the above-mentioned components into the mixing tank, stir and mix at room temperature at a shear rate of 3000r / min for 1 hour, and then ultrasonically disperse for 2-4 hours.

[0050] (2) Grinding and filtering the above components to remove mechanical impurities.

[0051] (3) Add curing agent 30 minutes before construction, and construction can be carried out.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com