Odorless environment-friendly dried diatom ooze powder and preparation method thereof

A diatom mud, environment-friendly technology, applied in the field of architectural coatings, can solve the problems of poor adhesion, high formaldehyde content, powder drop, etc., and achieve the effect of good low-temperature film-forming performance and high adhesion performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

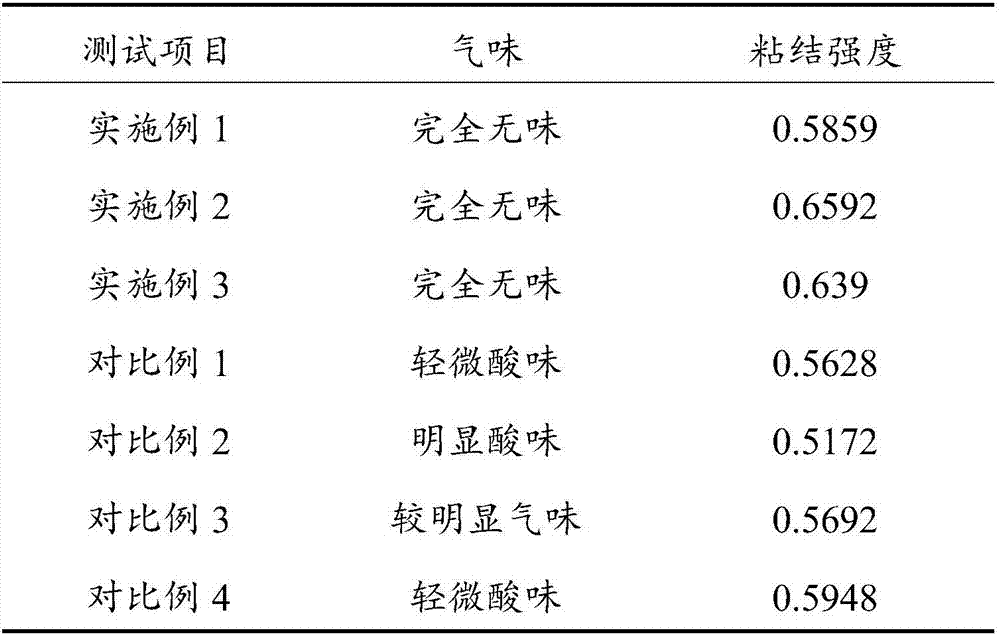

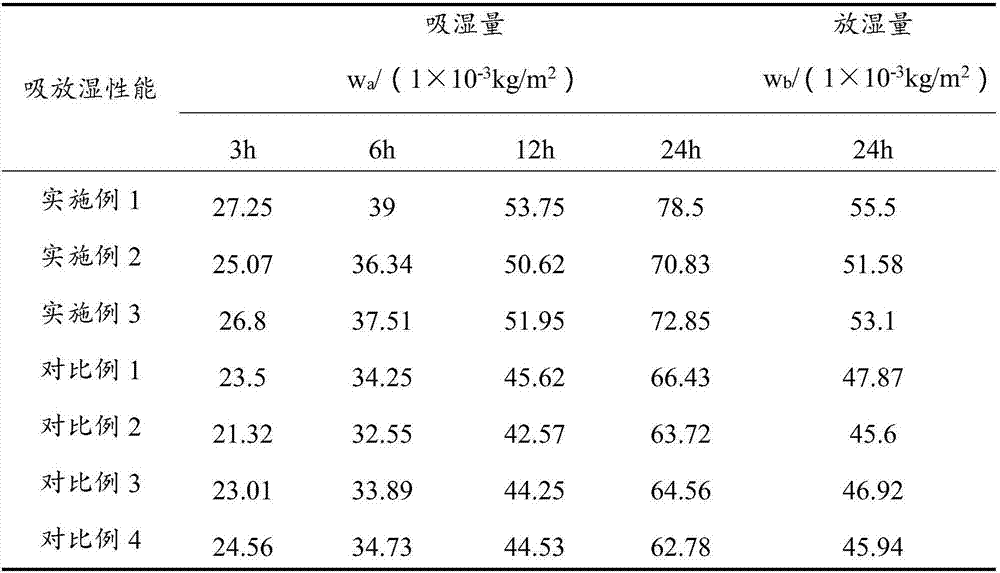

Examples

Embodiment 1

[0031] An odorless and environment-friendly dry powder diatom mud includes the following components by mass: 3 parts of 6088G rubber powder, 20 parts of diatomaceous earth, 1 part of nano-titanium dioxide, 1 part of titanium dioxide, 10 parts of ash calcium, 10 parts of heavy calcium, quartz powder 5 parts, 10 parts of kaolin, 0.3 parts of hydroxypropyl methylcellulose ether, and 0.1 part of starch ether.

[0032] Among them, the diatomite is non-calcined diatomite of 325-1250 mesh; the particle size of the nano-titanium dioxide is 5-10 nm; the titanium dioxide is rutile titanium dioxide; the whiteness of the gray calcium is ≥90, mesh The number is 325-1000 mesh; the heavy calcium is two kinds of 400 mesh and 800 mesh; the mesh number of the quartz powder is 20-40 mesh; the kaolin is calcined kaolin with 1250 mesh.

[0033] The preparation method of the above-mentioned odorless and environment-friendly dry powder diatom mud comprises the following steps: mixing the above-menti...

Embodiment 2

[0035] An odorless and environmentally friendly dry powder diatom mud includes the following components by mass: 6 parts of 6088G rubber powder, 30 parts of diatomaceous earth, 3 parts of nano-titanium dioxide, 2 parts of titanium dioxide, 20 parts of ash calcium, 20 parts of heavy calcium, quartz powder 15 parts, 20 parts of kaolin, 0.5 parts of hydroxypropyl methylcellulose ether, and 0.2 parts of starch ether.

[0036] Wherein, the diatomite is non-calcined diatomite of 325-1250 mesh; the particle size of the nano-titanium dioxide is 5-10 nm; the titanium dioxide is anatase titanium dioxide; the whiteness of the gray calcium is ≥90, The mesh number is 325-1000 mesh; the mesh number of the heavy calcium is 1250 mesh; the quartz powder is two kinds of 40-80 mesh and 80-120 mesh; the kaolin is calcined kaolin with 3000 mesh.

[0037] The preparation method of the above-mentioned odorless and environment-friendly dry powder diatom mud comprises the following steps: mixing the a...

Embodiment 3

[0039] An odorless and environmentally friendly dry powder diatom mud includes the following components by mass: 7 parts of 6088G rubber powder, 40 parts of diatomite, 6 parts of nano-titanium dioxide, 30 parts of titanium dioxide, 35 parts of gray calcium, 30 parts of heavy calcium, quartz powder 45 parts, 30 parts of kaolin, 1 part of hydroxypropyl methylcellulose ether, and 0.5 part of starch ether.

[0040] Wherein, the diatomite is non-calcined diatomite of 325-1250 mesh; the particle size of the nano-titanium dioxide is 5-10 nm; the titanium dioxide is anatase titanium dioxide; the whiteness of the gray calcium is ≥90, The mesh number is 325-1000 mesh; the mesh number of the heavy calcium is 800 mesh; the mesh number of the quartz powder is 320 mesh; the kaolin is calcined kaolin with 1250 mesh.

[0041] The preparation method of the above-mentioned odorless and environment-friendly dry powder diatom mud comprises the following steps: mixing the above-mentioned 6088G rub...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Mesh | aaaaa | aaaaa |

| Mesh | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com