Preparation method of tin dioxide/metal sulfide composite electron transport layer and its application in perovskite solar cells

A technology of metal sulfide and electron transport layer, which is applied in the field of new material technology and new energy, can solve the problems of hindering the efficient output of charge current, reducing electron mobility, and low crystallinity of the film, and achieves the suppression of pinholes and charge traps Formation, improvement of electron mobility, high mobility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

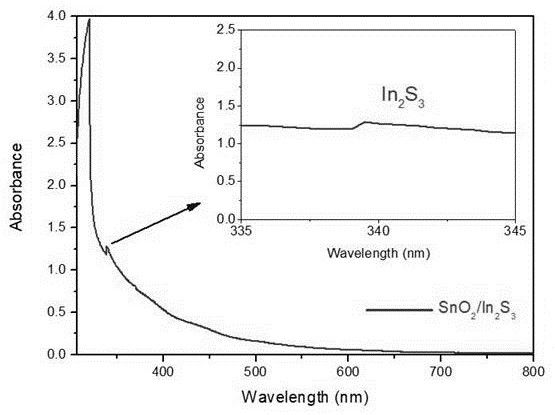

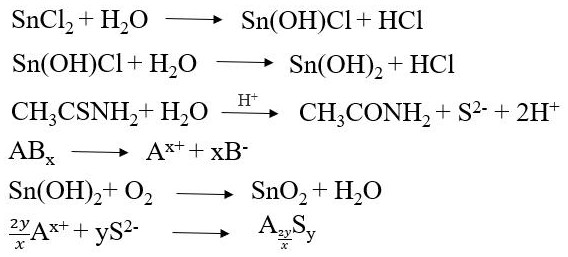

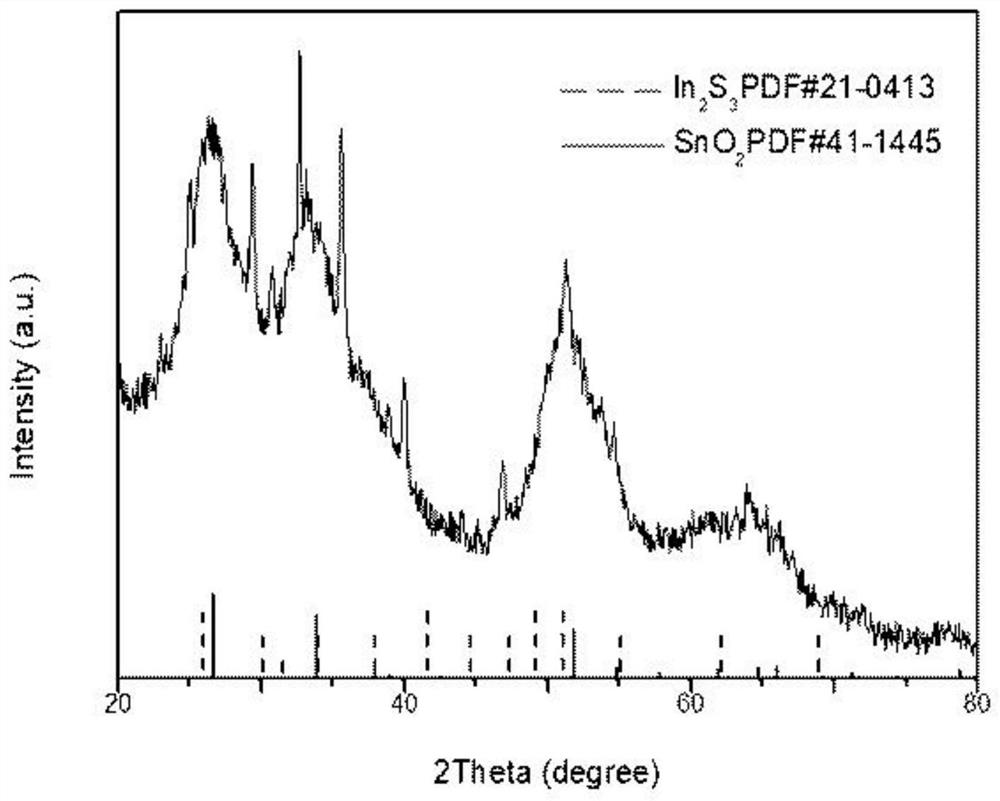

[0035] 1. Disperse stannous chloride, indium trichloride tetrahydrate, thioacetamide, and thiourea in 30 mL of deionized water; the respective amounts added are: stannous chloride is 0.15 mol / L, tetrahydrate trichloride Indium is 0.035mol / L, thioacetamide is 0.035mol / L, and thiourea is 0.1~0.2mol / L. Open stirring at 70 degrees for 36 hours, and the stirring speed is 700 rpm; the obtained mixed solution was centrifuged at 9000 rpm for 5 minutes and filtered with a 0.22 filter to obtain a supernatant compound of yellow tin dioxide and indium trisulfide. liquid;

[0036] 2. Prepare a DMF solution with a concentration of 1mol / L lead bromide (lead bromide is a solute, dissolved in DMF); prepare a cesium bromide methanol solution with a concentration of 0.07mol / L (cesium bromide is a solute, dissolved in methanol middle);

[0037] 3. The composite solution of tin dioxide and indium trisulfide was kept at 90 degrees for 30 minutes, then spin-coated at 2000 rpm for 30 seconds on the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| open-circuit voltage | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com