Preparation method of nanometer modified polymer super-hydrophobic coating

A super-hydrophobic coating and nano-modification technology, applied in coatings and other directions, can solve the problems of low coating strength, poor corrosion resistance, poor wear resistance, etc., and achieve the effect of increasing the interlayer distance and increasing the affinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

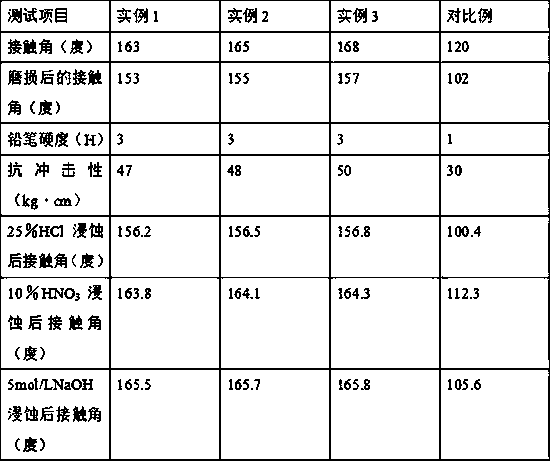

Examples

example 1

[0024]Mix ethyl orthosilicate, tridecafluorooctyltrimethoxysilane and absolute ethanol in a beaker at a volume ratio of 3:1:6, and stir for 16 minutes at a temperature of 35°C to obtain a stirred liquid. Then measure 12mL of ammonia water with a mass fraction of 21% and 36mL of absolute ethanol and mix and stir for 8 minutes to obtain a mixed solution; mix the stirred solution and the mixed solution in a volume ratio of 2:1 and place them in a beaker, continue the heat preservation and stirring reaction for 24 minutes, and stir After the reaction, put it in an oven, dry it at a temperature of 75°C for 35 minutes, grind and discharge the material to obtain a modified silica powder; weigh 55g of montmorillonite and put it into a kiln, and dry it at a temperature of 1050°C Calcined at low temperature for 32 minutes to obtain the calcined product. After cooling naturally to room temperature, the calcined product and deionized water were mixed and stirred for 21 minutes according to...

example 2

[0026] Mix ethyl orthosilicate, tridecafluorooctyltrimethoxysilane and absolute ethanol in a beaker at a volume ratio of 3:1:6, and stir for 19 minutes at a temperature of 40°C to obtain a stirred liquid. Then measure 14mL of ammonia water with a mass fraction of 21% and 40mL of absolute ethanol and mix and stir for 9 minutes to obtain a mixed solution; mix the stirred solution and the mixed solution in a volume ratio of 2:1 and place them in a beaker, continue the heat preservation and stirring reaction for 26 minutes, and stir After the reaction, put it in an oven, dry it for 40 minutes at a temperature of 78°C, grind and discharge the material to obtain a modified silica powder; weigh 57g of montmorillonite and put it into a kiln, and dry it at a temperature of 1070°C Calcined at low temperature for 34min to obtain the calcined product, after natural cooling to room temperature, the calcined product and deionized water were mixed and stirred for 23min according to the mass r...

example 3

[0028] Mix ethyl orthosilicate, tridecafluorooctyltrimethoxysilane and absolute ethanol in a beaker at a volume ratio of 3:1:6, and stir for 21 minutes at a temperature of 45°C to obtain a stirred liquid. Then measure 16mL of ammonia water with a mass fraction of 21% and 42mL of absolute ethanol and mix and stir for 10 minutes to obtain a mixed solution; mix the stirred solution and the mixed solution in a volume ratio of 2:1 and place them in a beaker, continue the heat preservation and stirring reaction for 27 minutes, and stir After the reaction, put it in an oven, dry at 80°C for 45 minutes, grind and discharge the material to obtain modified silica powder; weigh 60g of montmorillonite and put it into a kiln. Calcined under the conditions of 36min to obtain the calcined product, after natural cooling to room temperature, the calcined product and deionized water were mixed and stirred for 24min according to the mass ratio of 1:4 to obtain a suspension; the suspension and cet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com