Direct dynamic force measurement device of shock-wave-loaded double-raw model sphere array

A measuring device and dynamic force technology, applied in the analysis of materials, instruments, etc., can solve the problems that the gas phase parameters cannot be accurately controlled and measured, and the influence of the particle group spatial arrangement shock wave and the interference of the wake vortex structure cannot be reasonably considered, and achieve Effect of good experimental setup and test method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawings and examples.

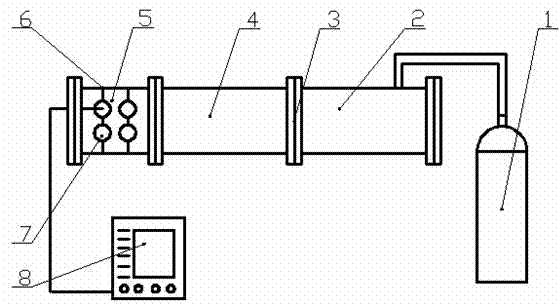

[0019] like figure 1 As shown, it includes a high-pressure air source 1, a driving section 2, a diaphragm 3, a driven section 4, a test section 5, a wire 6, a model ball 7 and a high-speed data acquisition system 8; one end of the driving section 2 and the driven section 4 One end of the diaphragm 3 is connected to form a shock tube, the high-pressure gas source 1 is connected to the other end of the driving section 2, one end of the test section 5 is connected to the other end of the driven section 4, and the acceleration in the model ball 7 in the test section 5 Meter sensor 12 leads are connected with high-speed data acquisition system 8.

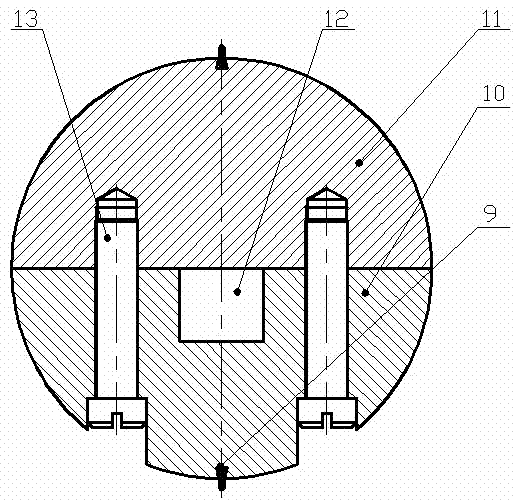

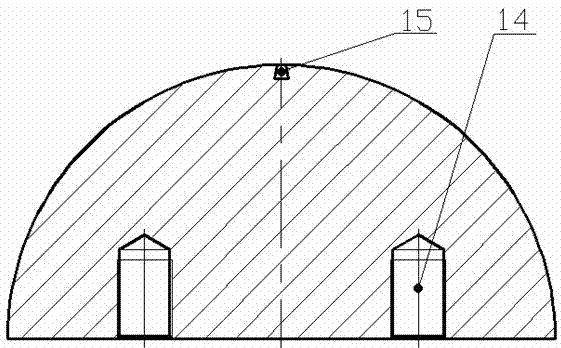

[0020] like figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 As shown, two rows of equidistantly distributed small holes 18 are arranged on the axial cylindrical surface of the test section 5, and the same r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com