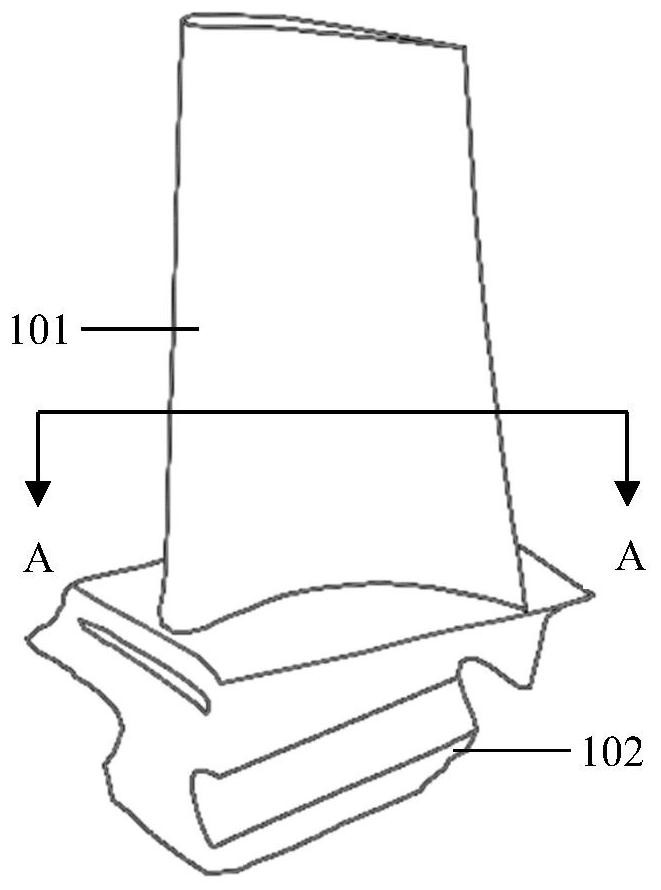

Method for preparing nano-carbides to enhance matrix stability based on eb-pvd

A carbide and stability technology, applied in the direction of solid-state diffusion coating, vacuum evaporation coating, coating, etc., can solve the difficulty of precise control of chemical decomposition process, difficulty of consistent control of carbon activity, and increase of carburizing results Fluctuation and other issues, to achieve the effects of inhibiting the formation of SRZ, improving high-temperature service performance, and inhibiting the decline in high-temperature mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0076] Step S1: Perform surface treatment on the single crystal superalloy substrate; specifically through steps S11 and S12:

[0077] Step S11: Use sandpaper from coarse to fine to polish the surface of the single crystal superalloy substrate in sequence, so that the surface roughness of the single crystal superalloy substrate is Ra<0.5, and the mesh number of the sandpaper used for the last grinding is 2000 mesh;

[0078] Step S12: Using absolute ethanol (99.7% content) to ultrasonically clean the above-mentioned single crystal superalloy substrate for 10 minutes, and repeat once to remove pollutants on the surface of the single crystal superalloy substrate;

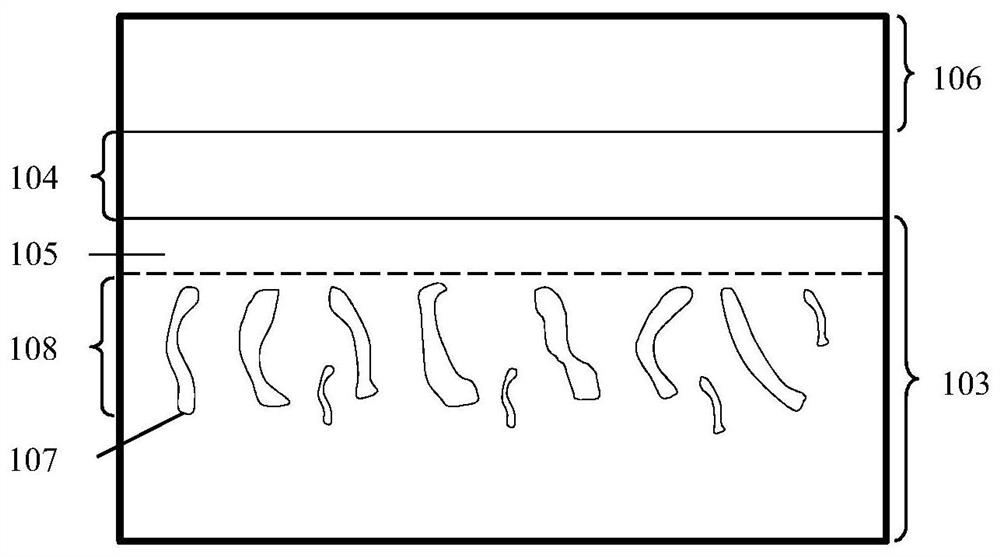

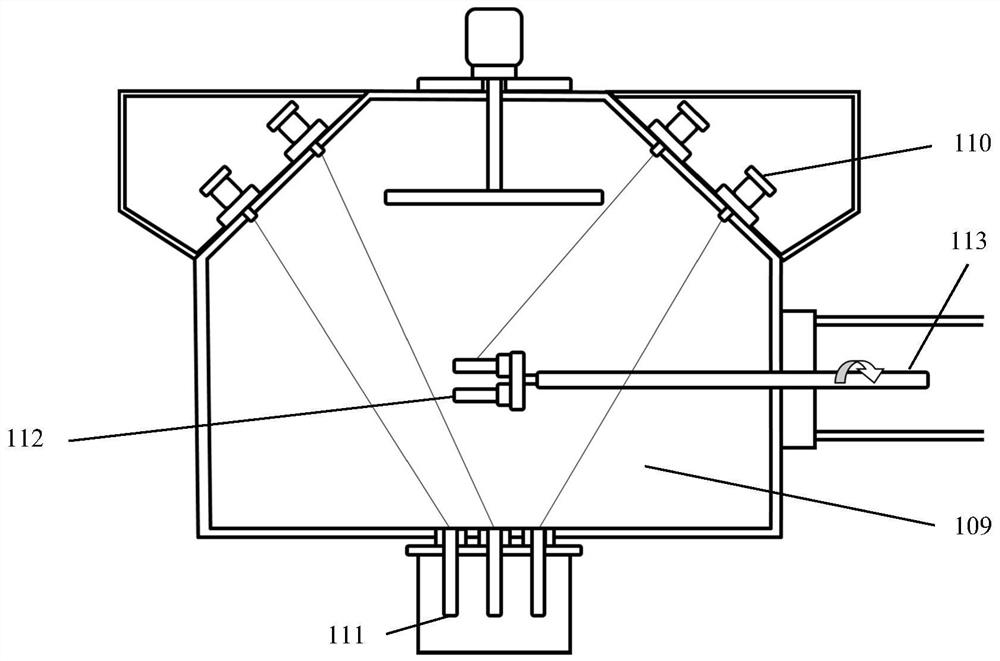

[0079] Step S2: Using EB-PVD equipment, using carbon rods as targets, depositing a carbon film on the surface of the single crystal superalloy substrate; specifically through steps S21 and S22:

[0080] Step S21: installing the single crystal superalloy substrate on the fixture of the EB-PVD equipment, and installing t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com