Downward hole pressure measuring device and process

A pressure measurement device and pressure measurement technology, which is applied in the direction of measurement, wellbore/well components, earthwork drilling and production, etc., can solve the problems of difficulty in measuring gas pressure in downholes, long measurement time, and poor reliability, so as to prevent the sealing material Effects of liquid leakage, measurement of gas pressure, and accurate gas pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

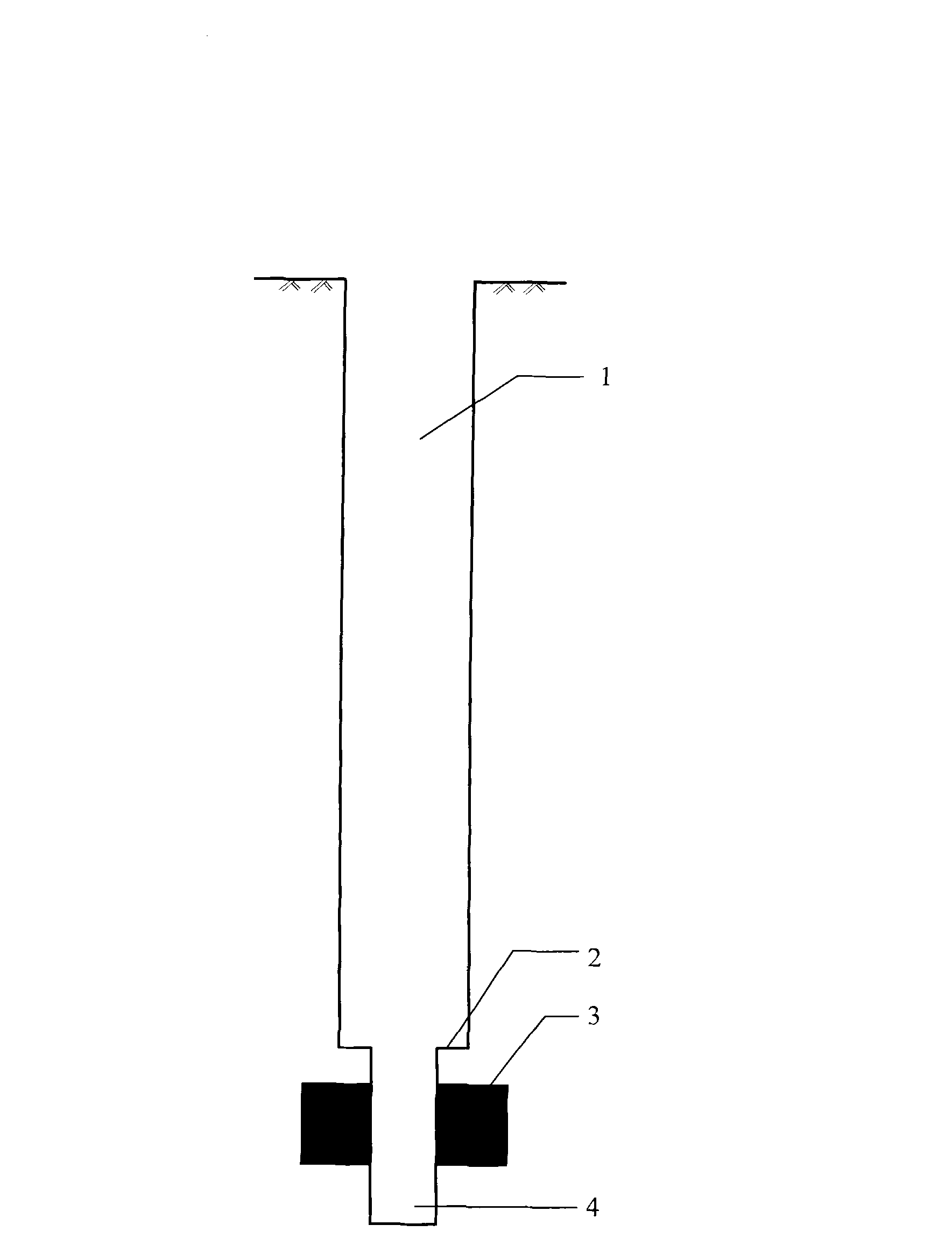

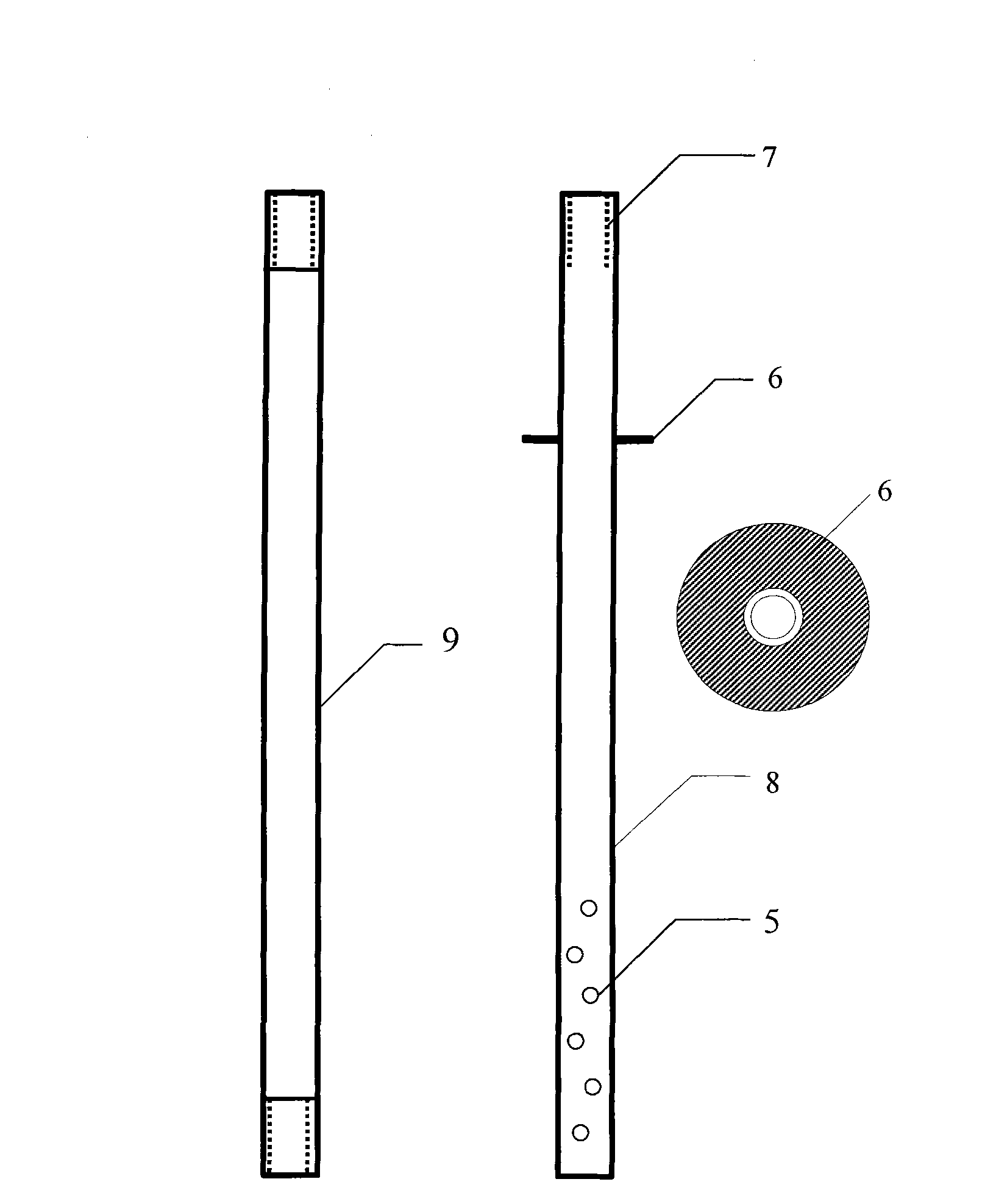

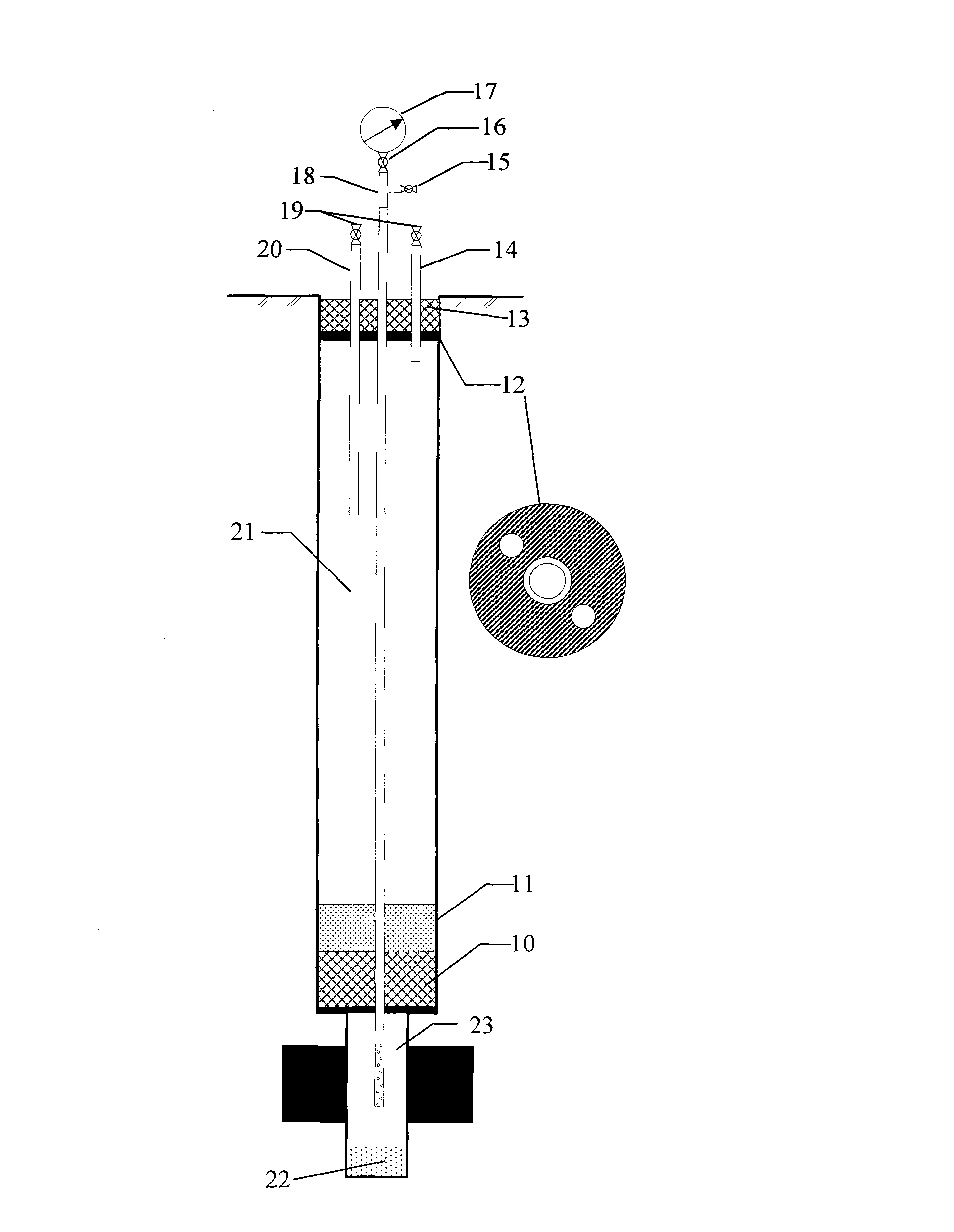

[0017] Example: see figure 1 It is a schematic diagram of the drilling structure. The characteristics of the drilling structure for the pressure measurement of the down hole in the coal mine are that the drilling with a diameter of ¢108mm is first constructed, and the drilling is stopped at a position 1-2m away from the measured coal seam, and the drill bit of ¢75mm is used to continue drilling to the bottom of the coal seam. Stop drilling at 3-4m, flush the borehole, drain the water in the borehole, and complete the pressure measurement drilling construction. figure 2 Schematic diagram of the implementation of the piezometric tube for the downhole. As shown in the figure, the piezometric tube is made of galvanized iron pipe with a diameter of 4 inches (industrial standard DN15), each of which is 2m long (easy to carry and install underground). Connection with pipe hoops; the first circular baffle plate of the pressure measurement common pipe is ¢105mm, the installation posit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com