Detonation excitation system and method based on high speed jet

A high-speed jet and excitation system technology, applied in the field of detonation excitation systems, can solve the problems of large total pressure loss, small spring blockage, and short detonation distance, so as to reduce total pressure loss, increase turbulence, and shorten detonation. effect of distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

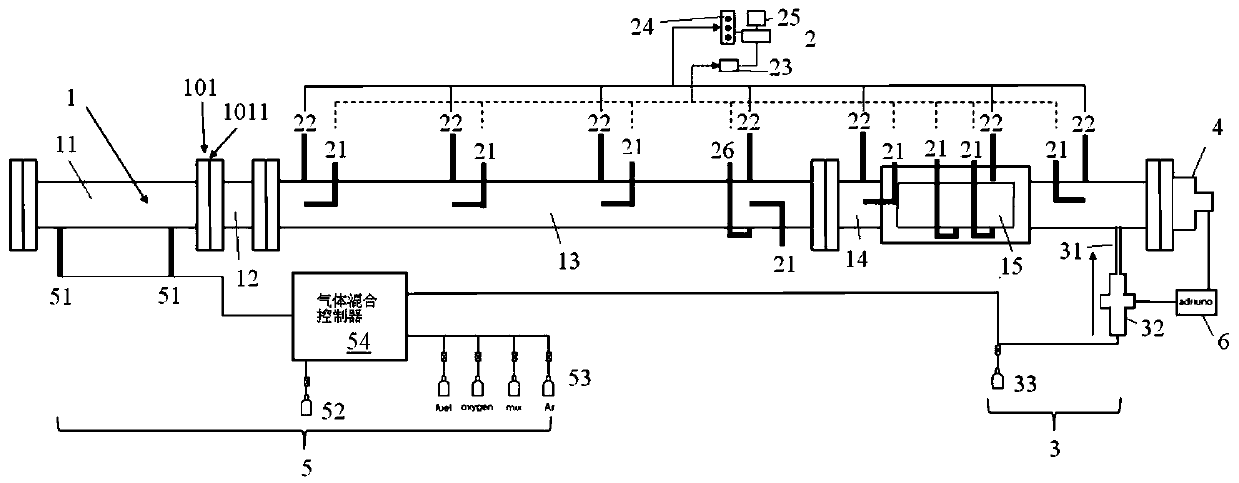

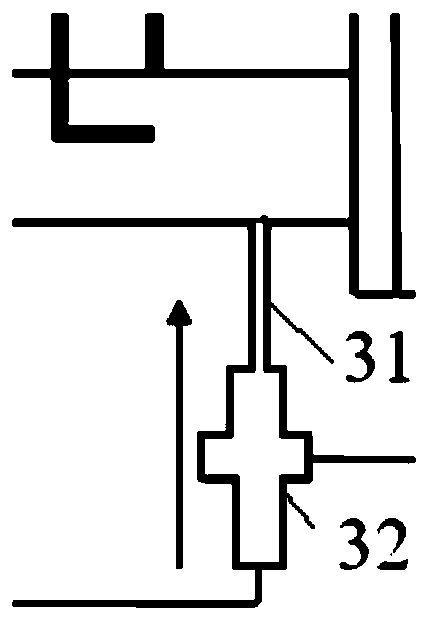

[0034] Such as figure 1 Shown is a high-velocity jet-based detonation excitation system according to an embodiment of the present invention, which includes a shock tube 1, which is provided with a plurality of openings, and passes through these openings along the shock tube 1 The length direction of the shock tube 1 is installed in sequence with the test mixed gas system 5, the data acquisition system 2 and the jet control system 3, and the end of the shock tube 1 is provided with the ignition system.

[0035] Among them, the shock tube 1 is designed to be composed of four test sections, and each test section is a square long straight steel pipe with a thickness of 10 mm and an inner diameter of 100 mm, and a flange 101 is passed between two adjacent test sections. Connected to facilitate processing and assembly. A diaphragm 1011 can be installed in the middle of the flange according to the experimental requirements to block the gas flow between the experimental sections.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com