Measuring system for pressure response time of pressure-sensitive paint and temperature response time of temperature-sensitive paint

A technology of pressure-sensitive coatings and response time, applied in material excitation analysis, fluorescence/phosphorescence, etc., can solve the problem that slow pressure-sensitive coatings can only be applied

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

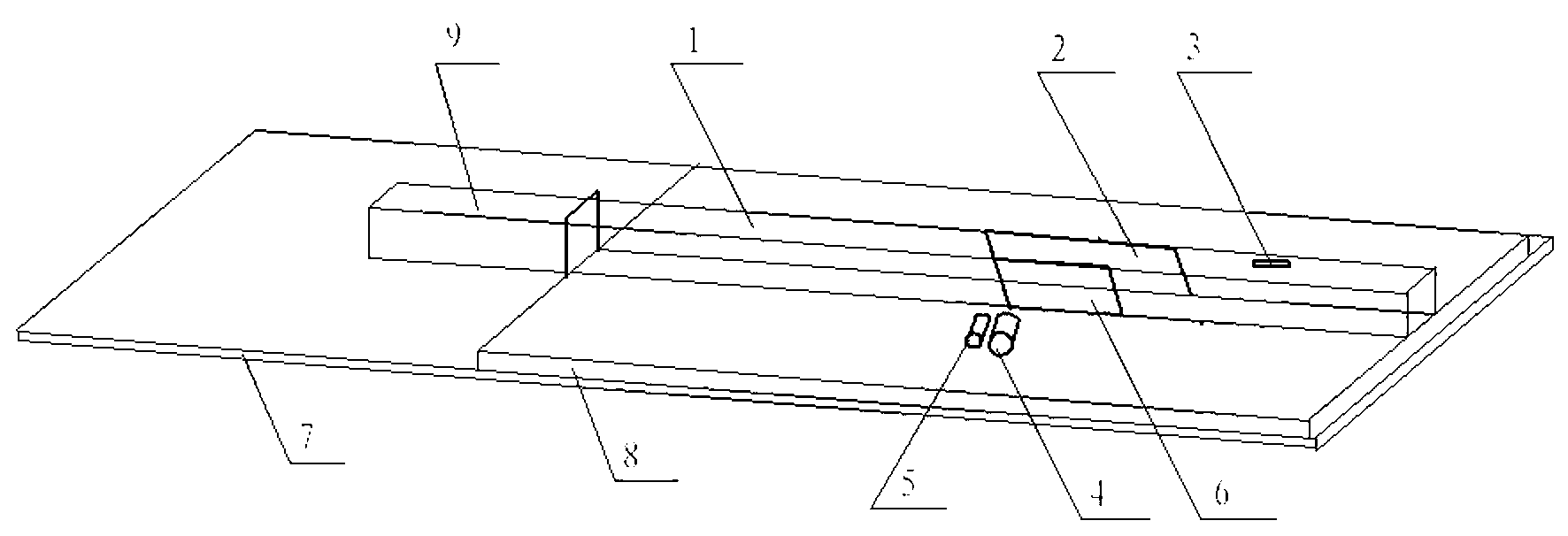

[0035] Pressure-sensitive paint pressure response time and temperature-sensitive paint temperature response time measurement system, including fixed workbench 8, sliding workbench 7, shock wave tube 1 for generating shock wave, shock tube test wall plate 2 for spraying pressure-sensitive paint 3. Dynamic pressure sensor used to monitor the shock wave sweeping through the shock tube test area 3. LED light source used to generate excitation light 4. Photomultiplier tube used to collect pressure-sensitive paint fluorescence intensity signals 5. As the shock tube optical test window Quartz optical glass windows6. The sliding table 7 is slidably connected to the fixed table 8, the shock tube 1 is fixedly connected to the sliding table 7 with the shock tube driving section 9, and the shock tube test section is placed on the fixed table 8, and the quartz optical glass The window 6 is arranged on the shock tube 1, and the quartz optical glass window is the optical channel of the measu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com