Supersonic gas-solid two-phase flow erosion and wear test device

A wear test, supersonic technology, applied in the direction of testing wear resistance, etc., can solve the problems of long test time of related equipment, insufficient research on multiphase flow wear, and difficulty in popularizing engineering applications of experimental results, etc., to achieve easy promotion and optimization The effect of simple design and structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with drawings and embodiments.

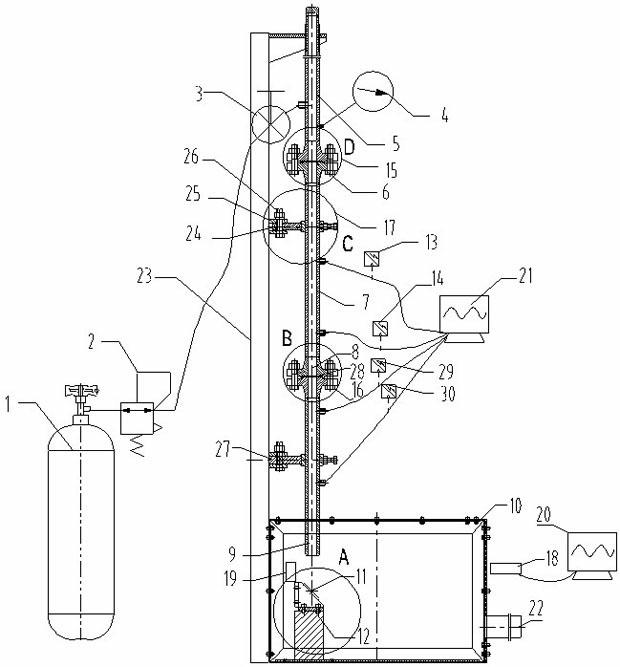

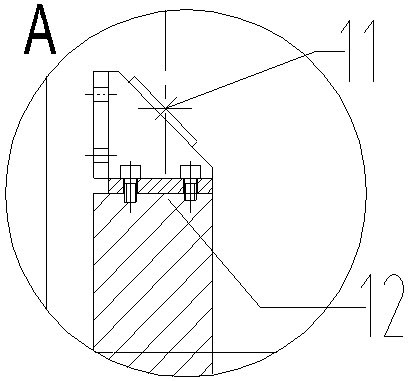

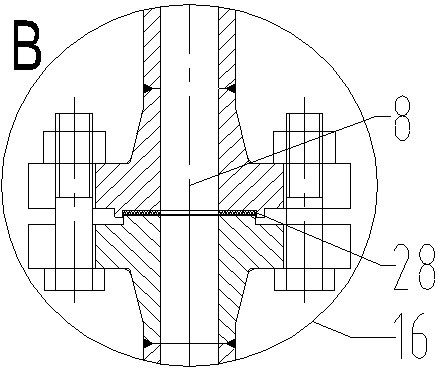

[0024] Such as figure 1 As shown, the present invention includes a high-pressure gas cylinder 1, a pressure reducing valve 2, a needle valve 3, a pressure gauge 4, a driving section 5, a driven section 7, an observation section 9, a gas collection box 10, a test piece 11, and a test piece installation Platform 12, four pressure sensors 13, 14, 29, 30, high pressure-butt welding flat head flange 15, driven-loaded butt welding flat head flange 16, first moving frame 17, high-speed camera 18, industrial control computer 20, Oscilloscope 21, the first floating connection frame 24, the second floating connection frame 27; the outlet of high pressure gas cylinder 1 is connected to the inlet of needle valve 3 through pressure reducing valve 2 and metal hose, and the outlet of needle valve 3 is connected to the driving section through metal hose 5 air intake holes are connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com