Compound nanofiber diaphragm for lithium ion power battery and manufacturing method

A nanofiber, power battery technology, applied in battery pack parts, chemical instruments and methods, circuits, etc., can solve the problem of poor heat resistance, poor safety, and small difference between film breaking temperature and closed-cell temperature of power lithium battery separators. problems, to achieve the effect of increasing the closed-cell temperature difference, enhancing safety, and increasing the film breaking temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

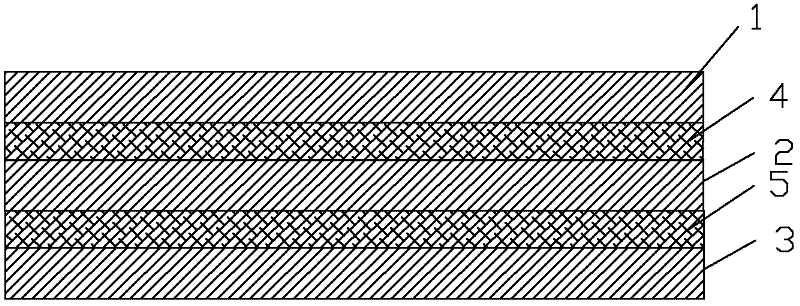

[0045] refer to figure 1 , a composite nanofiber separator for a lithium-ion power battery, the composite nanofiber separator for a lithium-ion power battery includes an upper layer 1, an upper middle layer 4, a middle layer 2, a lower middle layer 5, and a lower layer 3; the upper layer 1, the middle layer 2 and The lower layer 3 is a PET nanofiber layer, the middle and upper layers 4 and the middle and lower layers 5 are PE nanofiber layers, the middle and lower layers cover the lower layer, the middle layer covers the middle and lower layers, and the middle and upper layers cover On the middle layer, the upper layer overlies the upper middle layer;

[0046] In the composite nanofiber separator for lithium-ion power batteries, the mass content of the upper layer, middle layer, and lower layer is independently 17-21%, and the upper-middle layer and lower-middle layer are 19.5%-23.5%;

[0047] The upper and lower layers both include PET, SEBS, PS-g-ECMA and nano TiO 2 , the ...

Embodiment 2

[0062] refer to figure 1 , in the present embodiment, the mass content of the upper layer is 18.5%, the mass content of the middle and upper layers is 23.5%, the mass content of the middle layer is 17%, the mass content of the middle and lower layers is 20.5%, and the mass content of the lower layer is 21%.

[0063] In the upper layer and the lower layer, the mass ratio of the four components is: 15 parts of PET, 1.1 parts of SEBS, 2.1 parts of PS-g-ECMA, nano-TiO 2 1.1 copies;

[0064] In the middle and lower layers, the mass ratio of the four components is: 15 parts of PET, 1.1 parts of SEBS, 1.6 parts of PS-g-ECMA, nano-TiO 2 1.1 copies;

[0065] The middle and lower layers and the middle and upper layers include PE, PS-g-ECMA and nano TiO 2 , the mass ratio of the three components is: 18 parts of PE, 1.6 parts of PS-g-ECMA, nano-TiO 2 0.6 parts.

[0066] Other schemes of this embodiment are all the same as in Embodiment 1.

Embodiment 3

[0068] refer to figure 1 , In the present embodiment, the mass content of the upper layer is 21%, the mass content of the middle and upper layers is 19.5%, the mass content of the middle layer is 21%, the mass content of the middle and lower layers is 19.5%, and the mass content of the lower layer is 20%.

[0069] In the upper layer and the lower layer, the mass ratio of the four components is: 15 parts of PET, 1.2 parts of SEBS, 2.3 parts of PS-g-ECMA, nano-TiO 2 1.4 copies;

[0070]In the middle and lower layers, the mass ratio of the four components is: 15 parts of PET, 1.4 parts of SEBS, 2.1 parts of PS-g-ECMA, nano-TiO 2 1.35 copies;

[0071] The middle and lower layers and the middle and upper layers include PE, PS-g-ECMA and nano TiO 2 , the mass ratio of the three components is: 18 parts of PE, 2.2 parts of PS-g-ECMA, nano-TiO 2 01.2 parts.

[0072] Other schemes of this embodiment are all the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com