Double-diaphragm rupture warning device of metering pump

An alarm device and double-diaphragm technology, applied in the field of metering pumps, can solve the problems of polluted medium or hydraulic oil, misleading staff, false alarm signals, etc., to achieve simple and easy use conditions, reduce production costs and production difficulties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

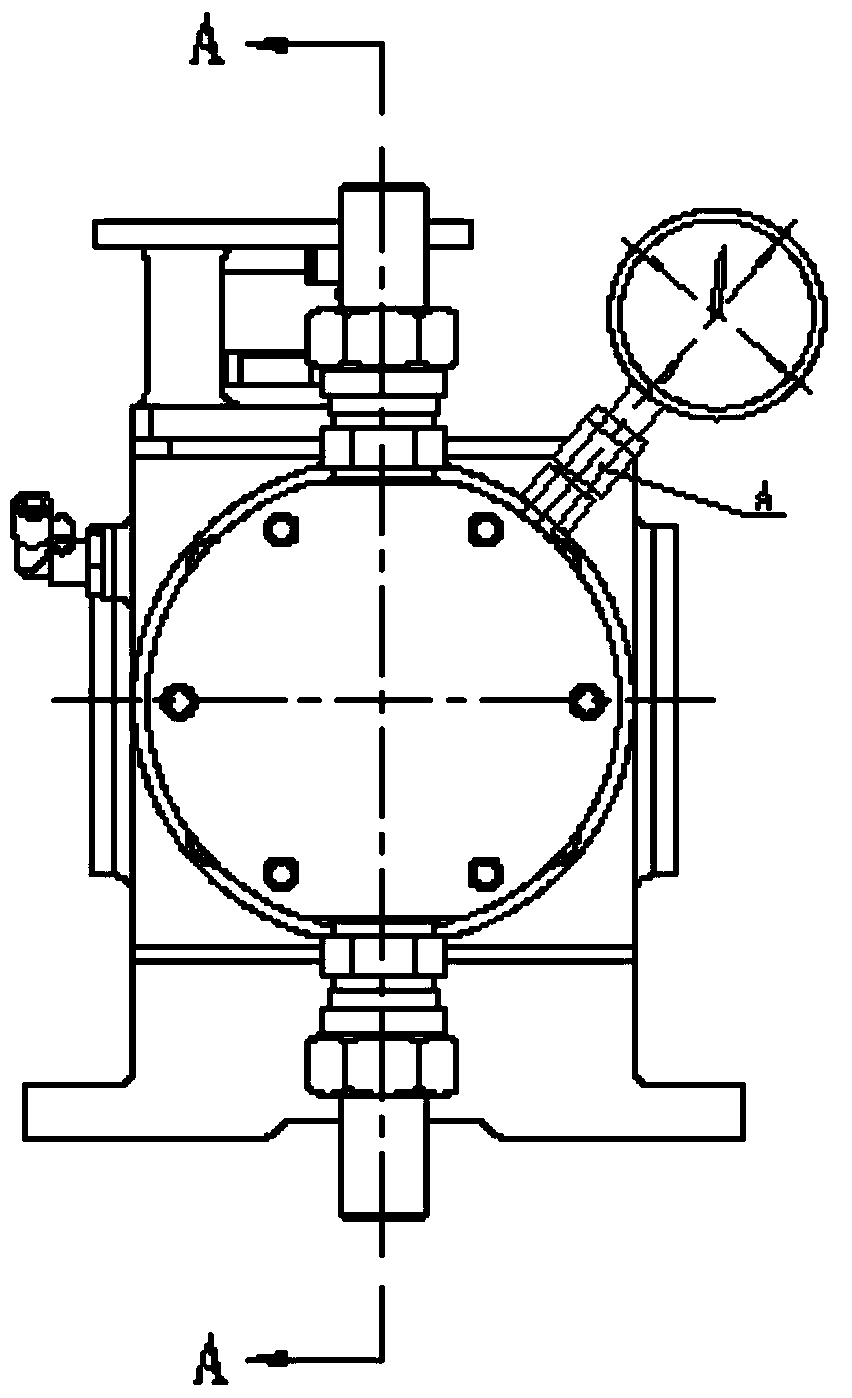

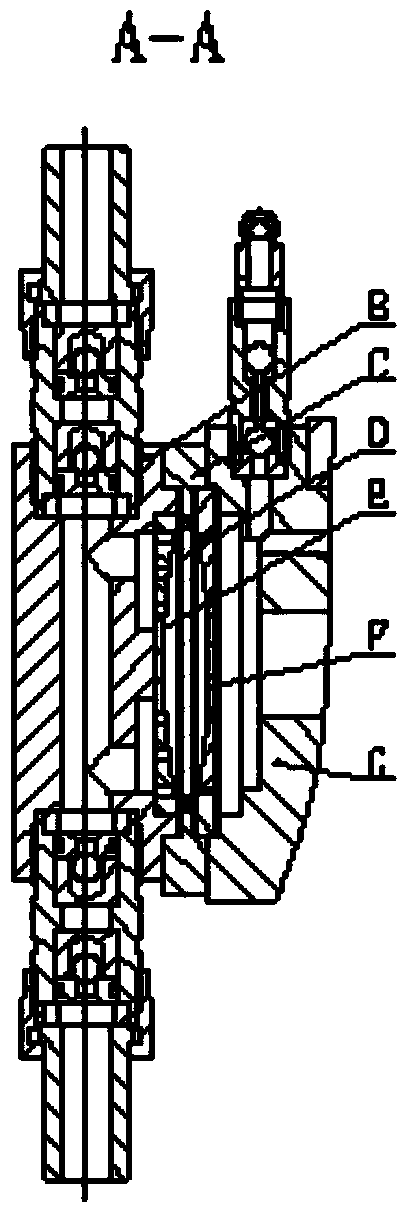

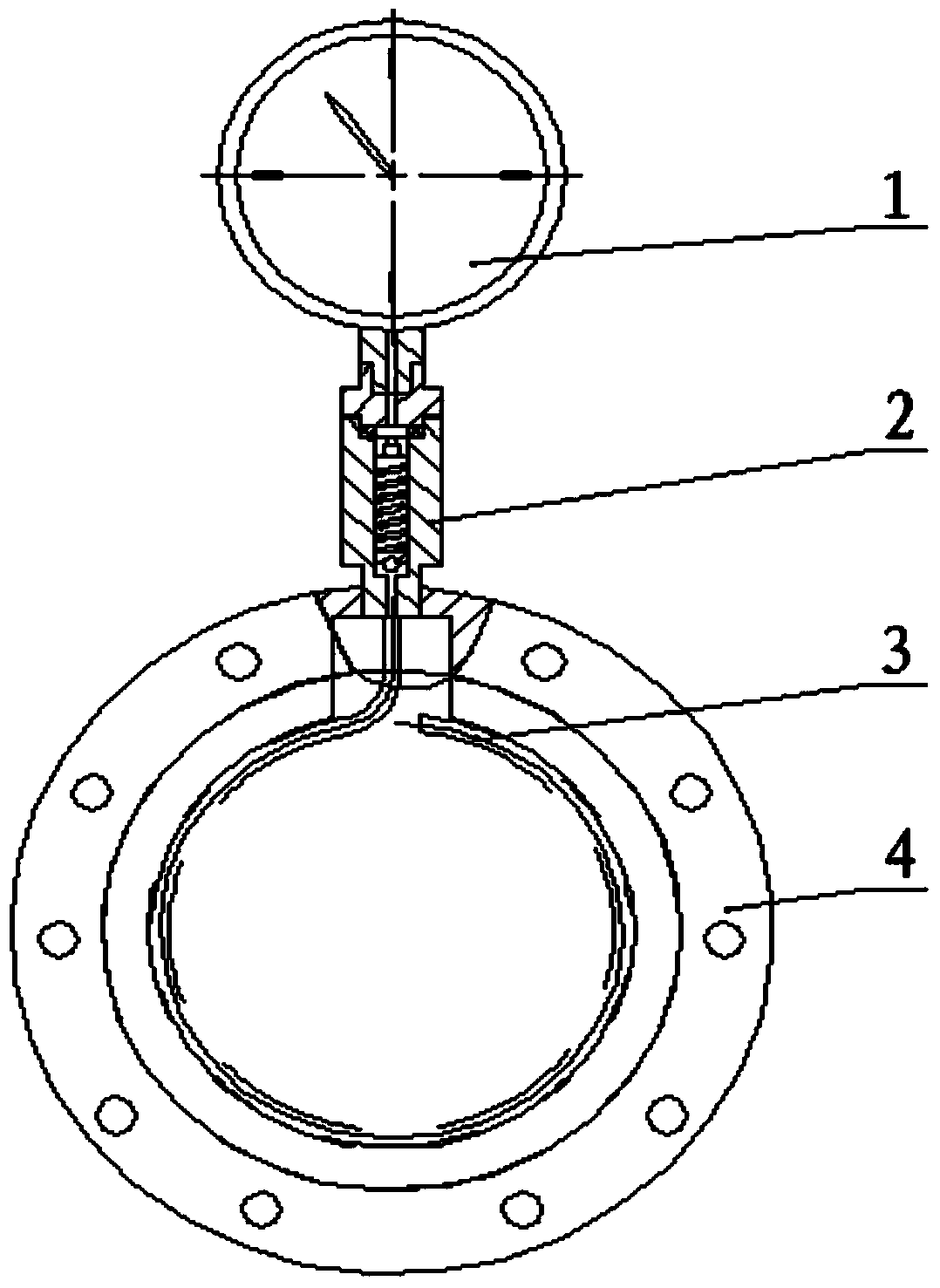

[0026] Such as figure 1 , figure 2 and image 3 As shown, a metering pump double-diaphragm rupture alarm device includes a double-diaphragm seal ring 4, and the double-diaphragm seal ring 4 is fixed between the pump head B and the pump cylinder G of the metering pump by bolts, and a metering pump is arranged on it. Diaphragm E on the pump head side and diaphragm D on the pump cylinder side are installed and fixed. The top of the double-diaphragm seal ring 4 is a pressure output channel and is connected to an adjustable pressure filter valve 2. The inner side of the double-diaphragm seal ring 4 is closely attached to an annular pressure sampling Pipe 3, the body of the annular pressure sampling pipe 3 is evenly distributed with cross pressure sampling holes, the top of which is connected to the pressure output channel of the double ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com