Self-operated axial flow pressure regulating valve fully open in case of failure

A failure, self-operated technology, applied in the field of pressure regulating valves, can solve the problems of equipment shutdown and the inability to predict and judge the damage degree of the working pressure regulating valve, and achieve the effect of reducing investment cost, low manufacturing cost and stable performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

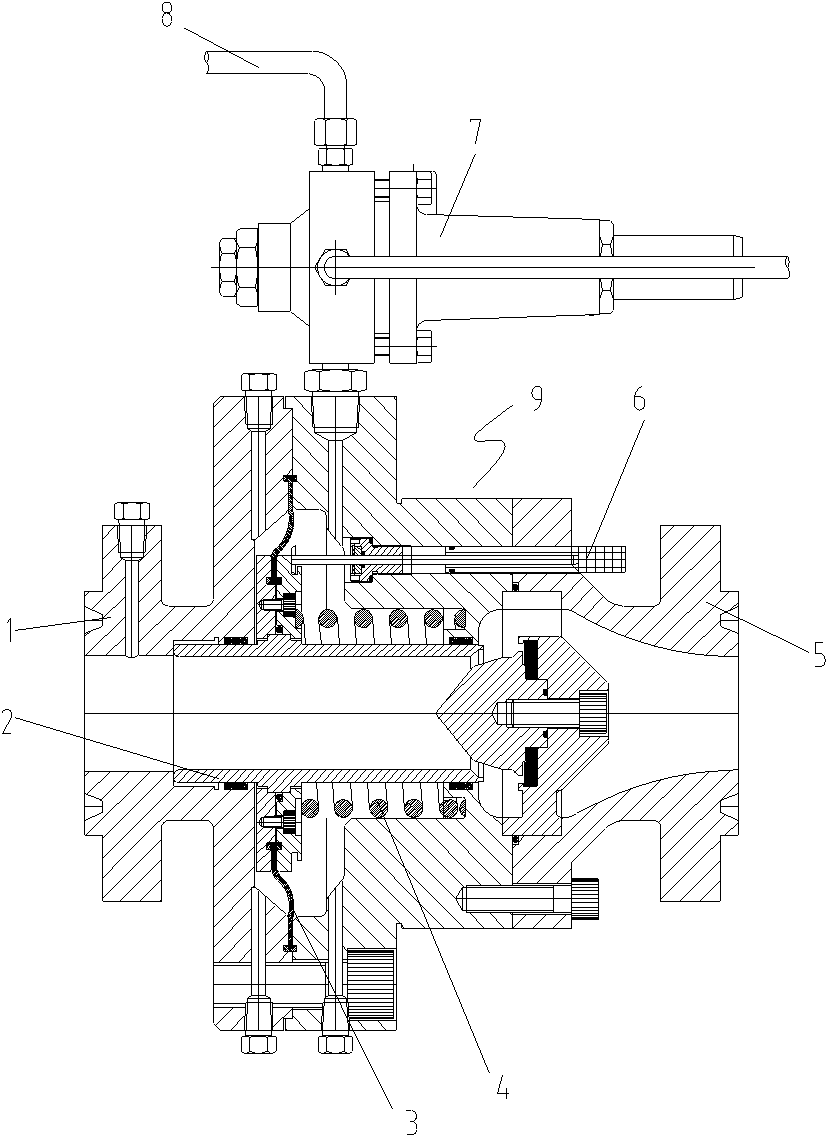

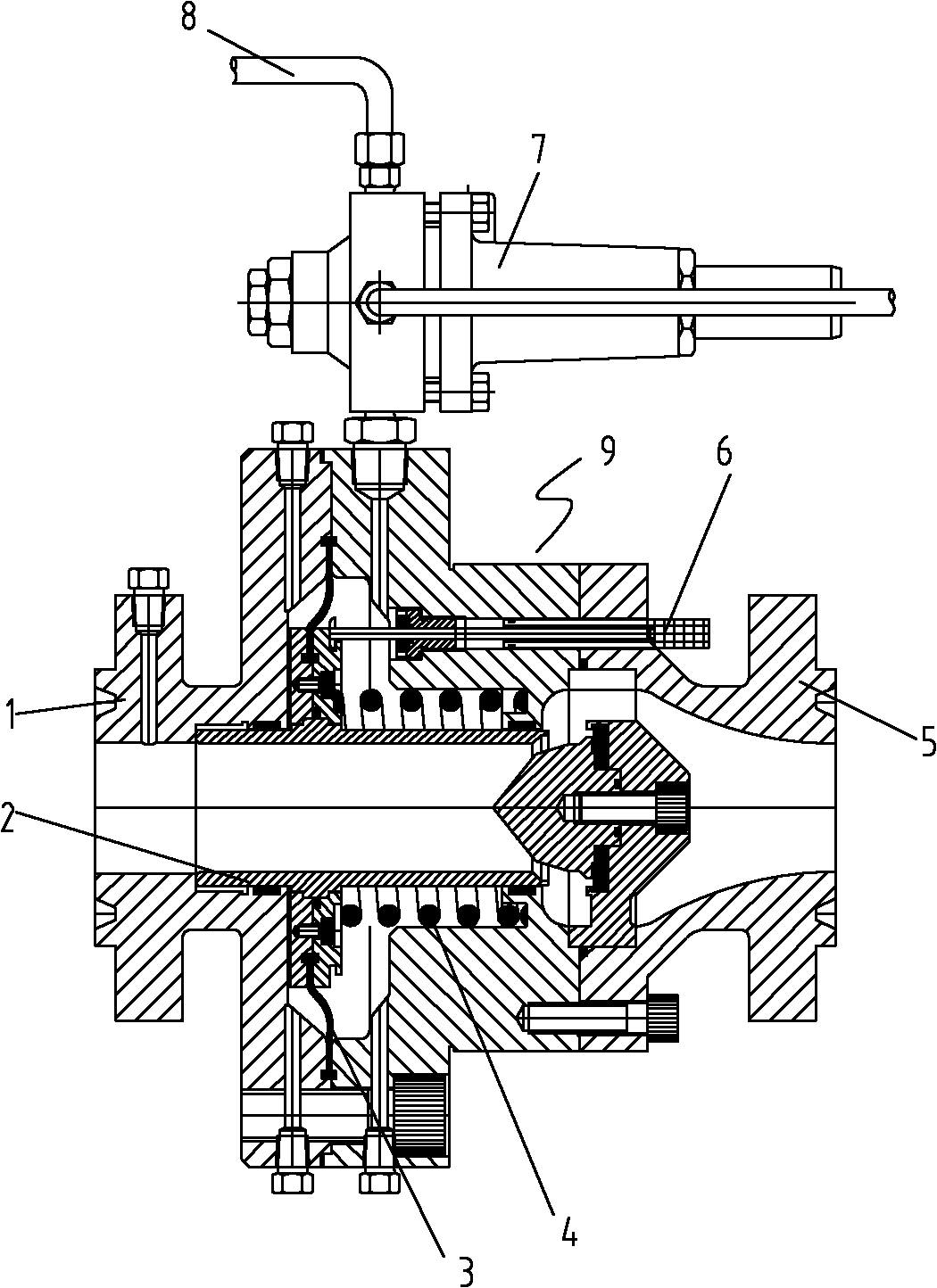

[0010] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments. As shown in the figure, a self-operated axial flow pressure regulating valve that fully opens in case of failure includes a valve body 9 with an inlet 1 before pressure regulation and an outlet 5 after pressure regulation, a valve core 2, a membrane 3, an opening spring 4, The position sensor 6, the control indicators 7 and 8 are pressure-taking nozzles, and the opening spring of the inner chamber of the valve is placed at the rear of the membrane diaphragm.

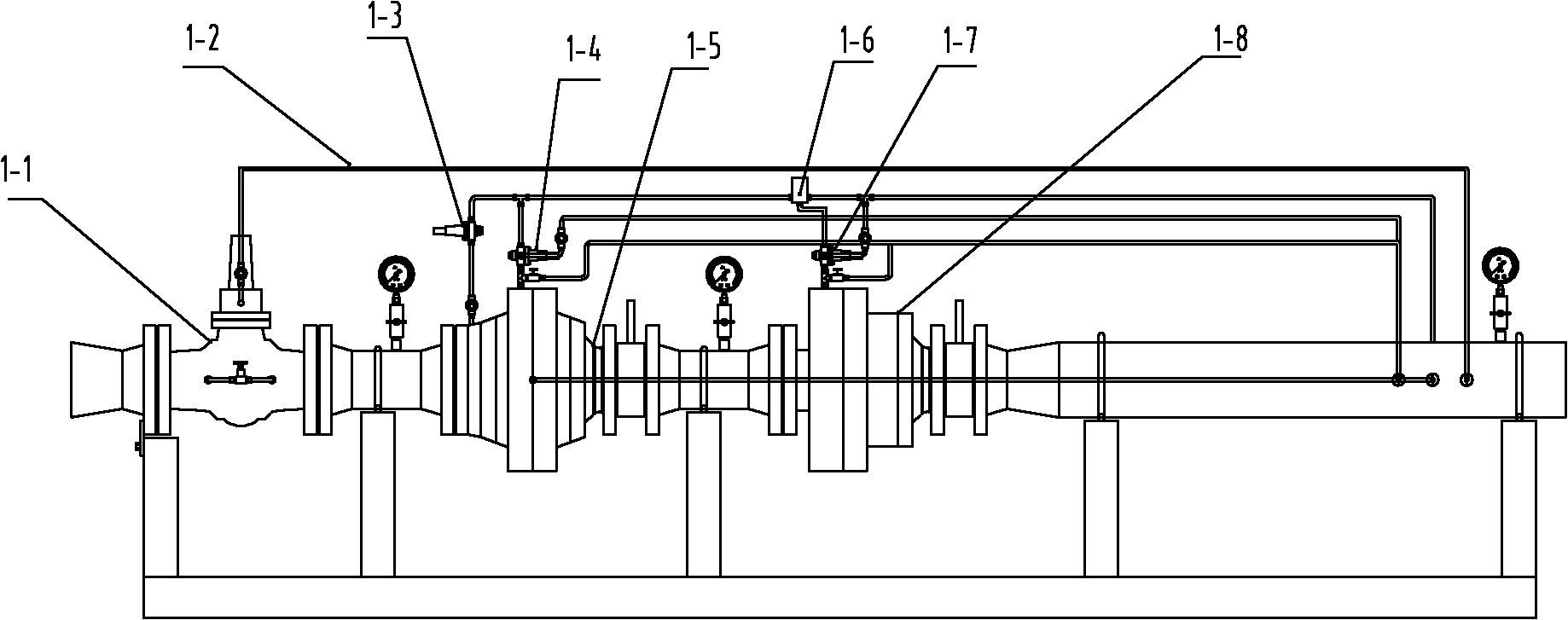

[0011] Such as figure 2 As shown, 1-1 safety emergency shut-off valve, 1-2 sampling pipe (pressure pipe), 1-3 front pilot, 1-4 control pilot, 1-5 failure-closed self-operated axial flow pressure regulating valve (monitoring), 1-6 front (pilot) 1-7 control pilot 1-8 failure open type self-operated axial flow pressure regulating valve. The self-oper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com