Diaphragm, preparation method thereof, secondary battery and electric equipment

A diaphragm and base film technology, applied in secondary batteries, battery pack components, circuits, etc., can solve problems such as poor shrinkage performance, inability to meet low shrinkage and high membrane rupture temperature at the same time, and inability to further improve the safety performance of the diaphragm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0077] The preparation process of the base film will be described below. It can be understood that the following preparation method is only an optional preparation method of the base film, and the preparation method of the base film is not limited to the following preparation methods.

[0078] Figure 4 For the preparation method of the base film of a kind of embodiment of the present application, such as Figure 4 As shown, as an illustration, in one embodiment of the present application, the preparation method of the base film includes the following steps:

[0079] Step S11, mixing the polyolefin resin raw material and solvent to obtain a mixed melt: melt and knead the polyolefin resin raw material, solvent and additives in a twin-screw extruder to form a uniform liquid phase; wherein, the boiling point of the solvent higher than the mixing temperature.

[0080] Among them, the polyolefin resin raw material is designed according to the required functions of the polyolefin...

Embodiment 1

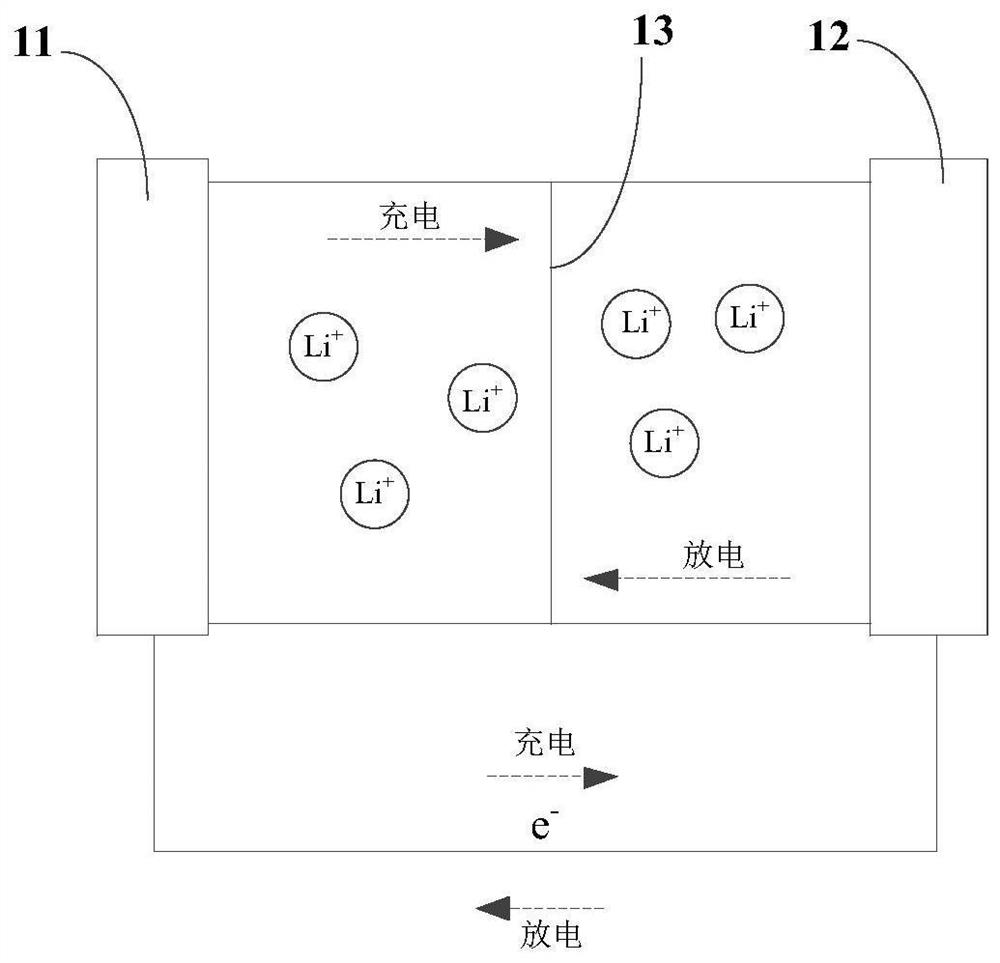

[0125] The application is a lithium ion battery, and the specific raw materials and preparation process of the lithium ion battery are as follows:

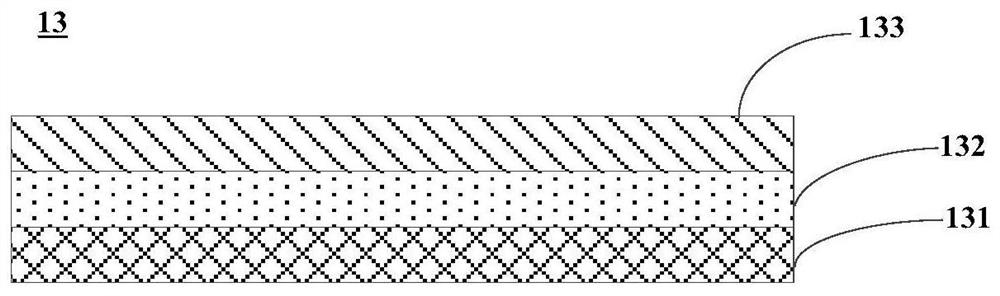

[0126] Step (1) Base Membrane (A): Preparation of Polyolefin Porous Membrane

[0127] Polyolefin composition: Ultra-high molecular weight polyethylene with a melting point of 136°C and a molecular weight of 1 million, low-melting polyethylene with a melting point of 125°C and a molecular weight of 600,000; polypropylene with a melting point of 165°C and a molecular weight of 500,000 in a ratio of 55:30:15 Ratio and paraffin oil are melted and mixed at high temperature in a twin-screw extruder, the ratio of polyolefin composition to paraffin oil is 25:75, the mixing temperature is 190-220°C, and the homogeneous melt passes through a slot die Head extrusion, casting on cooling rollers to form a gel sheet, the cooling rate is 85°C / min; then the gel sheet is first stretched 5 times in the MD direction, and then stretched 5 times in th...

Embodiment 2-47

[0139] Examples 2 to 47 are respectively a lithium ion battery, and the preparation method of the separator is referred to in Example 1. The specific raw materials and structural parameters of the separator are listed in Table 1.

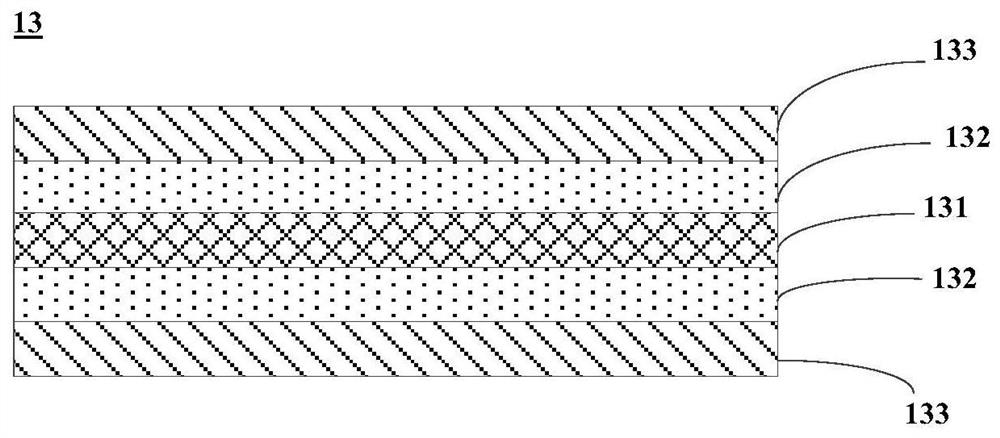

[0140] Among them, in the lithium-ion battery of Examples 42-47, the diaphragm also includes the step of coating an adhesive layer after coating the organic coating during the preparation process. The specific coating process of the adhesive layer is as follows: the adhesive resin PVDF Dissolve in good solvent N-methylpyrrolidone to form a mixed solution with a concentration of 3%, and then disperse alumina inorganic particles in the above mixed solution to form a coating slurry, wherein the mass ratio of PVDF to alumina is 60%: 40%. The uniformly dispersed slurry is coated on the diaphragm obtained in step (3) by gravure reverse roller coating on both sides at the same time, and the diaphragm covered with the adhesive layer is obtained after coagul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Membrane rupture temperature | aaaaa | aaaaa |

| Membrane rupture temperature | aaaaa | aaaaa |

| Closed cell temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com