Coated diaphragm and preparation method thereof

A coating and diaphragm technology, applied in the direction of separators/films/diaphragms/spacers, electrical components, circuits, etc., can solve the problem of affecting the weight and electrochemical performance of batteries, hindering the migration channel and rate of lithium ions, and increasing the battery life. The difficulty of core injection and other issues can be improved to improve the rate performance and cycle performance, reduce the risk of deformation, and reduce the effect of adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

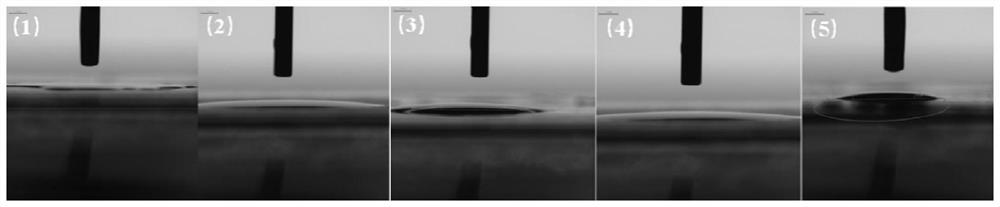

Image

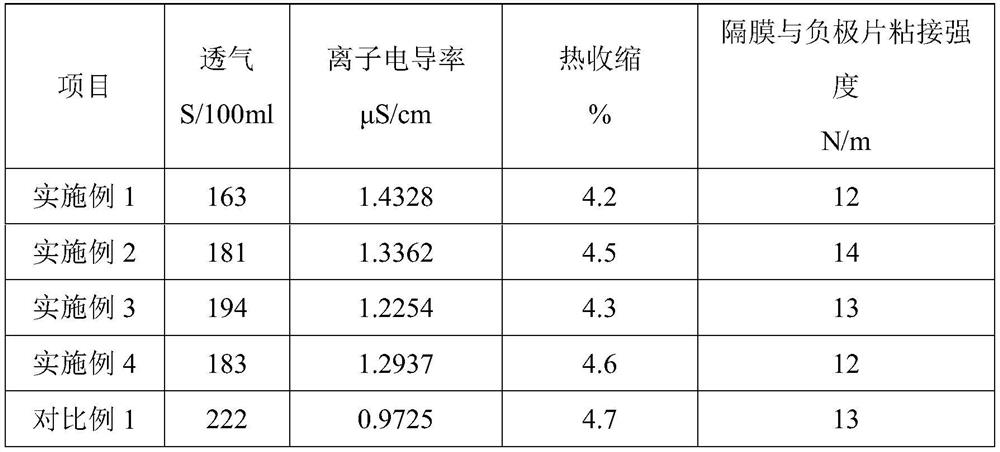

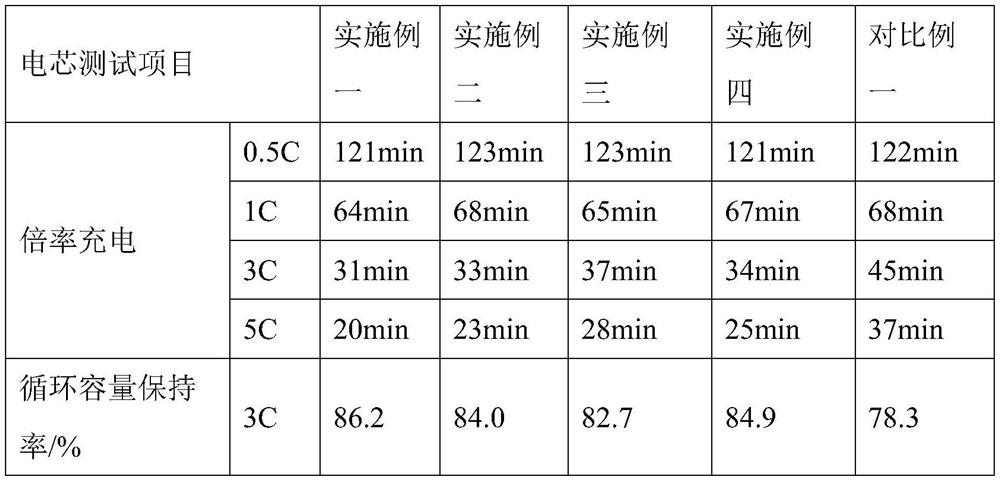

Examples

Embodiment 1

[0034] Example 1 This example provides a coated separator, which contains porous PMMA microspheres with a particle size D50 of 3.8 μm, a porosity of 35%, and an average pore size of 150 nm.

[0035] Concrete preparation method is as follows:

[0036] Step S1, preparing porous PMMA microspheres;

[0037] Preparation 500ml mass fraction is 2% polyvinyl alcohol (PVA) aqueous solution, in PVA solution, add 19.5g MMA monomer, 0.1g benzoyl peroxide and 10.5g n-octanol, stir with 65r / min at 70 ℃ React for 24 hours; after the polymerization is completed, fully wash with water, filter and dry; repeatedly soak the dried product in n-butanol, wash and filter three times, and fully dry to finally obtain a particle size D50 of 3.8 μm, a porosity of 35%, and an average pore size of Porous PMMA microspheres with a size of 150 nm.

[0038] Step S2, preparation of aqueous slurry;

[0039] Add 48g of aluminum oxide and 1.2g of sodium carboxymethylcellulose dispersant to 133.3g of deionized w...

Embodiment 2

[0042] Example 2 This example provides a coated separator, which contains porous PMMA microspheres with a particle diameter D50 of 2.7 μm, a porosity of 23%, and an average pore diameter of 85 nm.

[0043] Concrete preparation method is as follows:

[0044] Step S1, preparing porous PMMA microspheres;

[0045] Configure 500ml of 2% polyvinyl alcohol (PVA) aqueous solution, add 22.5g of MMA monomer, 0.1g of benzoyl peroxide and 7.5g of n-octanol to the PVA solution, and stir the reaction at 100r / min at 70°C for 24 hours After the polymerization is completed, it is fully washed with water, filtered and dried; the dried product is repeatedly soaked, washed and filtered three times with n-butanol, and fully dried to finally obtain a particle size D50 of 2.7 μm, a porosity of 23%, and a pore size of 85 nm. Porous PMMA microspheres.

[0046] Step S2, preparation of aqueous slurry;

[0047]Add 48g of aluminum oxide and 1.2g of sodium carboxymethylcellulose dispersant to 133.3g of ...

Embodiment 3

[0050] Example 3 This example provides a coated separator, which contains porous PMMA microspheres with a particle diameter D50 of 1.2 μm, a porosity of 11%, and an average pore diameter of 35 nm.

[0051] Concrete preparation method is as follows:

[0052] Step S1, preparing porous PMMA microspheres;

[0053] Configure 500ml of 2% polyvinyl alcohol (PVA) aqueous solution, add 26.4g of MMA monomer, 0.1g of benzoyl peroxide and 3.6g of n-octanol to the PVA solution, and stir the reaction at 135r / min at 70°C for 24 hours After the polymerization is completed, it is fully washed with water, filtered and dried; the dried product is repeatedly soaked, washed and filtered three times with n-butanol, and fully dried to finally obtain a particle size D50 of 1.2 μm, a porosity of 11%, and an average pore size of 40nm porous PMMA microspheres.

[0054] Step S2, preparation of aqueous slurry;

[0055] Add 48g of aluminum oxide and 1.2g of sodium carboxymethylcellulose dispersant to 13...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com