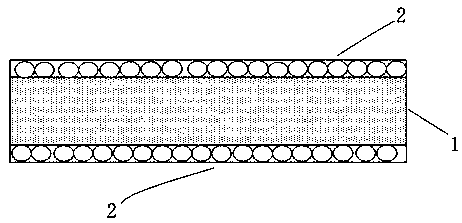

High-safety ceramic diaphragm for lithium ion battery and preparation method

A lithium-ion battery, high-safety technology, applied in the direction of battery pack parts, circuits, electrical components, etc., can solve the problems of battery positive and negative pole contact short circuit, diaphragm damage, easily punctured diaphragm, etc., to improve thermal shrinkage performance , Enhanced puncture strength, not easily damaged

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

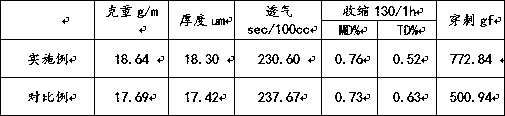

Examples

Embodiment 1

[0030] A preparation method for a high-safety ceramic diaphragm for lithium-ion batteries, comprising the following steps:

[0031] (1) Use solvent water to disperse the ammonium polyacrylate dispersant, then add alumina to disperse and stir for 60 minutes at a speed of 1500rpm, stir and disperse evenly before grinding, the weight ratio of dispersant to alumina is 0.0125:1.

[0032] (2) Add a carboxymethyl cellulose thickener to the solution obtained in step (1), and disperse for 30 minutes at a stirring rate of 30 rpm, and the weight-number ratio of the thickener to alumina is 0.4 :1.

[0033] (3) Add polyacrylate water-based adhesive to the mixed solution in step (2), and disperse for 30 minutes at a stirring rate of 30rpm, stir evenly, the weight parts of water-based adhesive and aluminum oxide The ratio is 0.2:1.

[0034] (4) Add a wetting agent and disperse for 30 minutes at a stirring rate of 30 rpm, stirring evenly. The weight-to-number ratio of the wetting agent to...

Embodiment 2

[0036] A preparation method for a high-safety ceramic diaphragm for lithium-ion batteries, comprising the following steps:

[0037] (1) Disperse the ammonium polyacrylate dispersant with solvent water, then add alumina to disperse and stir for 50 minutes at a speed of 1400rpm, stir and disperse evenly before grinding, the weight ratio of dispersant to alumina is 0.0125:1.

[0038] (2) Add carboxymethyl cellulose thickener to the solution obtained in step (1), and disperse for 40 minutes at a stirring rate of 20 rpm, and the weight-number ratio of thickener to alumina is 0.3 :1.

[0039] (3) Add polyacrylate water-based adhesive to the mixed solution in step (2), and disperse for 40 minutes at a stirring rate of 20rpm, stir evenly, the weight parts of water-based adhesive and aluminum oxide The ratio is 0.1:1.

[0040] (4) Add a wetting agent and disperse for 40 minutes at a stirring rate of 20 rpm, stirring evenly. The weight-to-number ratio of the wetting agent to the mix...

Embodiment 3

[0042] A preparation method for a high-safety ceramic diaphragm for lithium-ion batteries, comprising the following steps:

[0043] (1) Use solvent water to disperse the ammonium polyacrylate dispersant, then add alumina to disperse and stir for 70 minutes at a speed of 1600rpm, stir and disperse evenly before grinding, the weight ratio of dispersant to alumina is 0.0125:1.

[0044] (2) Add a carboxymethyl cellulose thickener to the solution obtained in step (1), and disperse for 20 minutes at a stirring rate of 40 rpm. The weight-number ratio of the thickener to aluminum oxide is 0.35 :1.

[0045] (3) Add polyacrylate water-based adhesive to the mixed solution in step (2), and disperse for 20 minutes at a stirring rate of 40rpm, stir evenly, the weight parts of water-based adhesive and aluminum oxide The ratio is 0.15:1.

[0046] (4) Add a wetting agent and disperse for 20 minutes at a stirring rate of 40rpm, stirring evenly. The weight-to-number ratio of the wetting agen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com