Novel diaphragm compressor

A diaphragm compressor and a new type of technology, applied in the field of compressors, can solve the problems of easy rupture of diaphragms, limitations of the size and specifications of diaphragm heads, etc., to achieve outstanding effects, improve stability and firmness, and improve the overall compression ratio.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

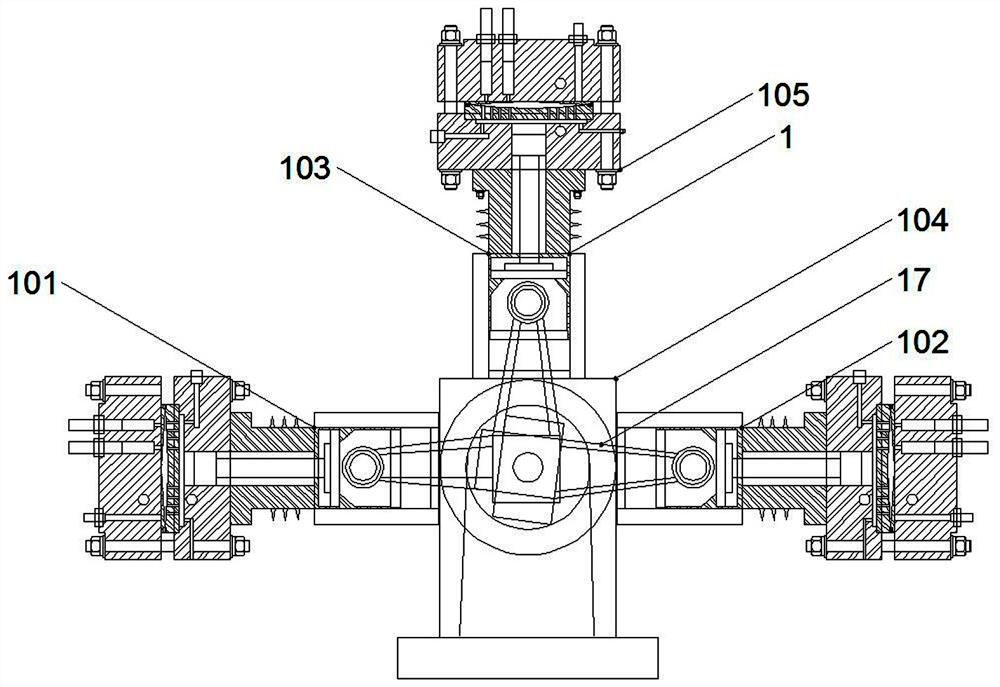

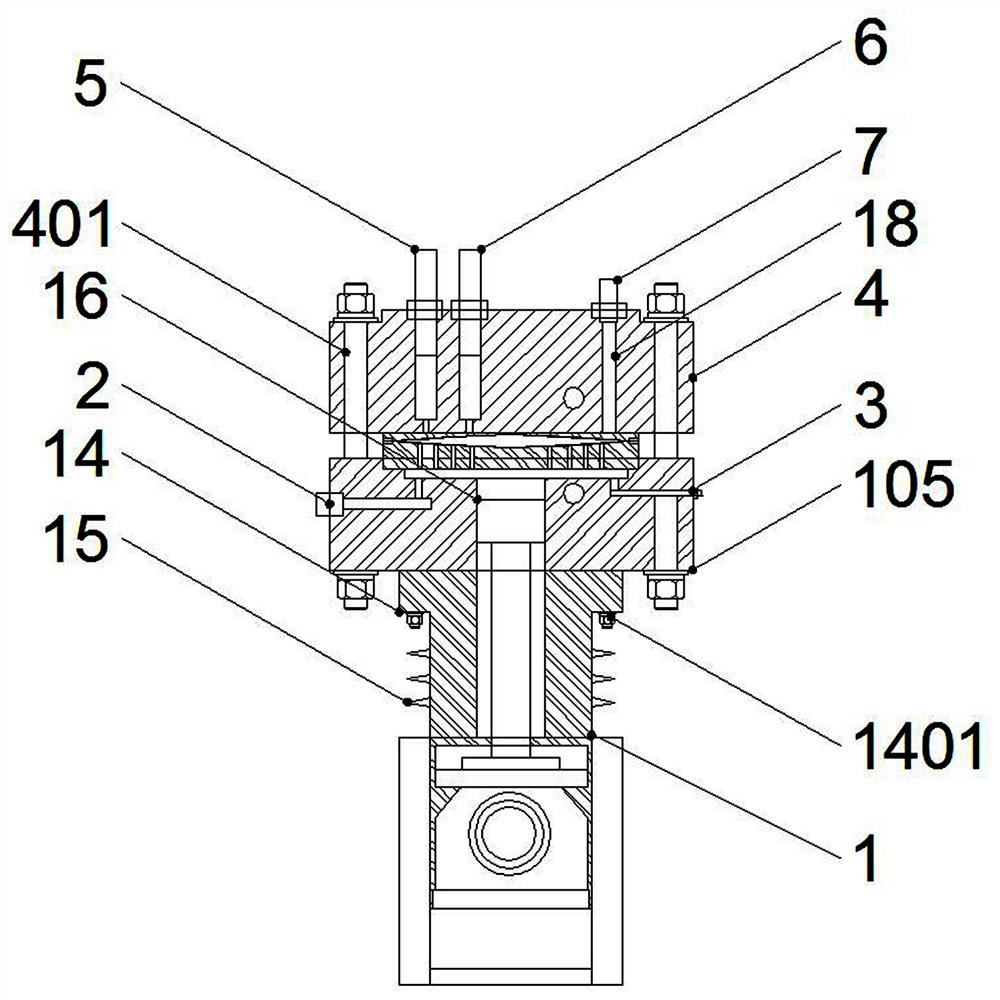

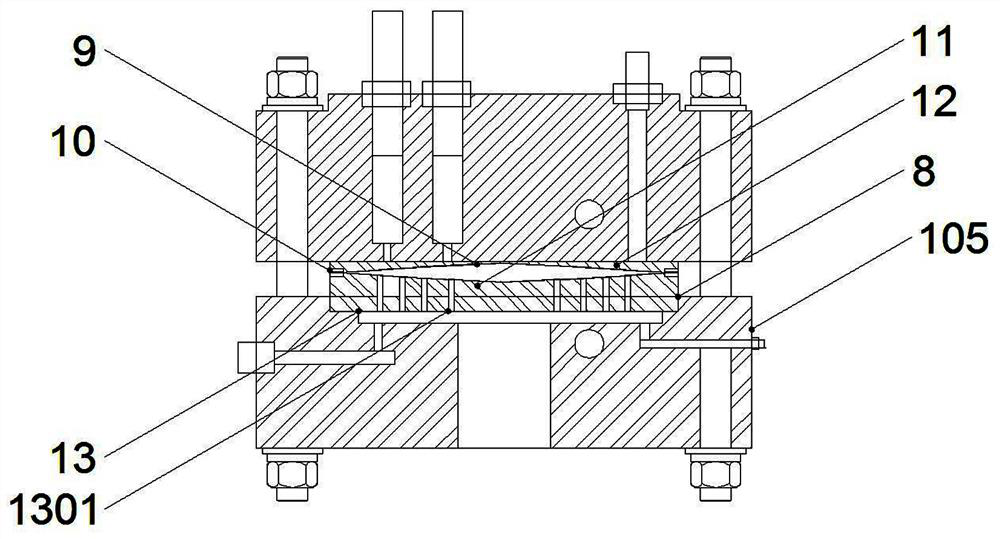

[0022] Example: such as Figure 1-3 As shown, a novel diaphragm compressor of the present invention includes a cylinder body 1, a primary cylinder 101, a secondary cylinder 102 and a tertiary cylinder 103, and the primary cylinder 101, the secondary cylinder 102 and the tertiary cylinder 103 are fixed and installed On one side of the base 104 , a cylinder head 105 is arranged on one side of the cylinder body 1 , an oil spill valve 2 is arranged on one side of the cylinder head 105 , and an oil replenishment valve 3 is arranged on the other side of the cylinder body 1 . The cylinder block 1 is provided with a cylinder head 4 at one time, and an inlet valve 5 is arranged on one side of the cylinder head 4, and an outlet valve 6 is arranged on one side of the inlet valve 5, and a liquid discharge valve 7 is arranged on one side of the outlet valve 6, and the cylinder head 4 and A housing chamber 8 is provided between the cylinders 1, a diaphragm 9 is arranged in the housing chamb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com