Thermal shutdown heat-resistant high-safety coated and modified membrane and preparation method thereof

A technology with high temperature resistance and thermal shutdown, which is applied in the direction of separators/films/diaphragms/spacers, electrical components, electrochemical generators, etc. The rapid development of ion battery technology and other issues, to achieve the effect of expanding the thermal shutdown temperature and membrane rupture temperature range, high membrane rupture temperature, and preventing battery short circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0063] A method for preparing a thermal shutdown high-temperature-resistant high-safety coated modified diaphragm, comprising the following steps:

[0064] (1) After dispersing and mixing the inorganic ceramic material and deionized water, add high-temperature-resistant resin and catalytic polyaddition organic matter, and stir evenly to obtain a uniformly dispersed ceramic / resin coating slurry;

[0065] (2) After dispersing and mixing the polymer microspheres and deionized water at high speed, add a water-based binder, a water-based wetting agent and a water-based dispersant, and stir evenly to obtain a uniformly dispersed polymer microsphere slurry;

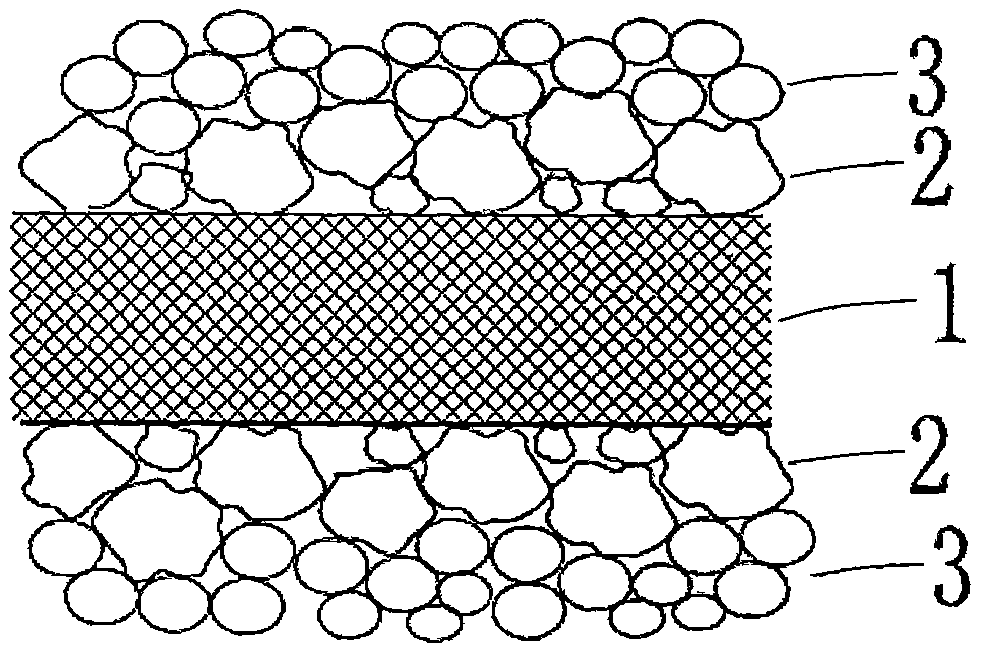

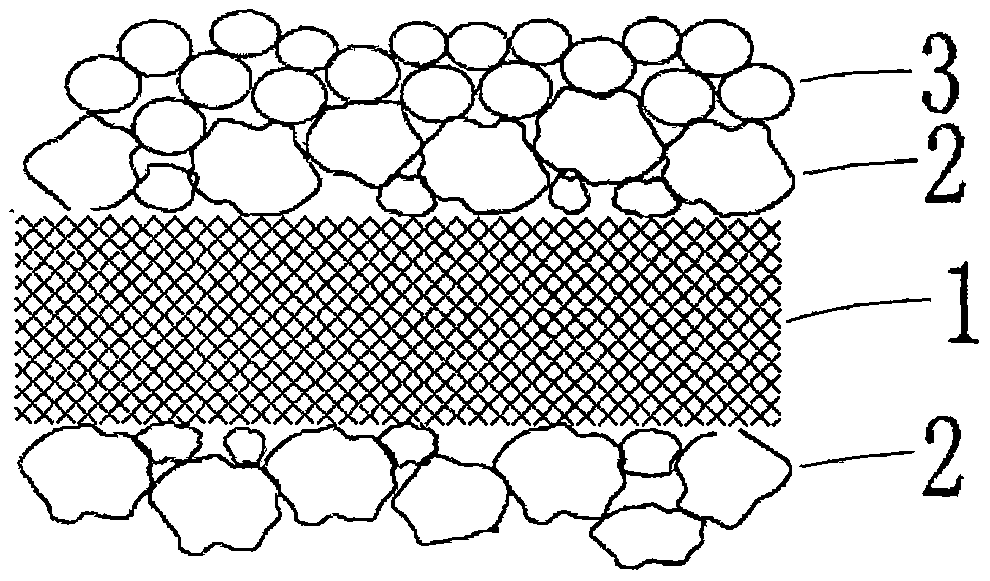

[0066] (3) coating the ceramic / resin coating slurry obtained in step (1) on one side or both sides of the base film, and after the ceramic coating is dried, a ceramic / resin diaphragm is obtained;

[0067] (4) Apply the polymer microsphere slurry obtained in step (2) to one or both sides of the ceramic / resin diaphragm obtained in...

Embodiment 1

[0072] (1) After dispersing and mixing 44wt% alumina powder (D50: 0.3μm, BET: 5.3m2 / g) and 50wt% deionized water at high speed, add 4wt% polyurethane resin and 2wt% catalytic polyaddition type Organic matter, after stirring evenly, a uniformly dispersed ceramic / resin slurry is obtained;

[0073] (2) After high-speed dispersion and mixing of 15wt% polymer microspheres and 70wt% deionized water, add 7wt% polymethyl acrylate, 4wt% sodium dodecylbenzenesulfonate and 4wt% polyacrylic acid, After uniform stirring, a uniformly dispersed polymer microsphere slurry is obtained;

[0074] (3) Coat the ceramic / resin slurry obtained in step (1) on both sides of the polypropylene microporous membrane by gravure coating, with a coating thickness of 2 μm on each side, and after the ceramic / resin coating is dried , to obtain a ceramic / resin diaphragm;

[0075] (4) The polymer microsphere slurry obtained in step (2) is coated on both sides of the ceramic / resin diaphragm obtained in step (3) b...

Embodiment 2

[0077] (1) After high-speed dispersion and mixing of 30wt% boehmite powder (D50: 2.0μm, BET: 0.5m2 / g) and 66wt% deionized water, add 3wt% epoxy resin and 1wt% catalytic polyaddition Type organic matter, after stirring evenly, a uniformly dispersed ceramic / resin slurry is obtained;

[0078] (2) After high-speed dispersion and mixing of 20wt% polymer microspheres and 60wt% deionized water, add 10wt% styrene-acrylic latex, 5wt% sodium aryl naphthalene sulfonate and 5wt% ammonium polyacrylate, and stir evenly Obtain the evenly dispersed polymer microsphere slurry;

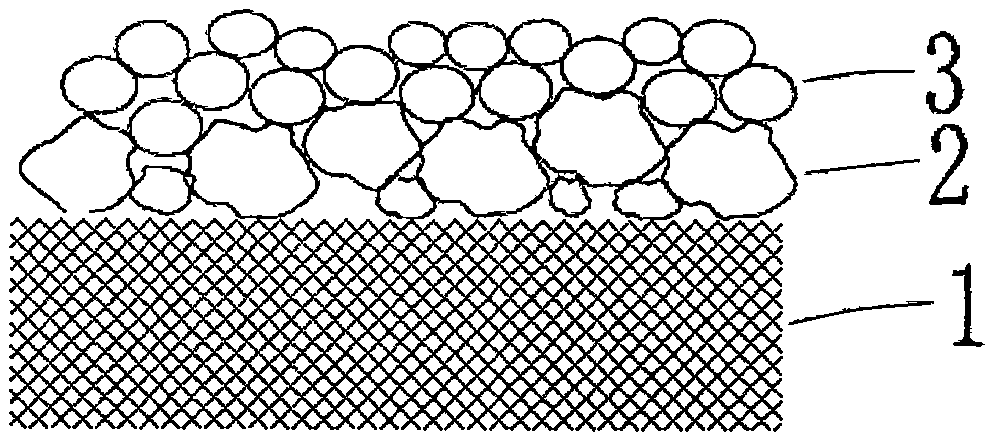

[0079] (3) Apply the ceramic / resin slurry obtained in step (1) to one side of the polyamide electrospinning membrane by dip coating, the coating thickness is 4 μm, after the ceramic / resin coating is dried , to obtain a ceramic / resin diaphragm;

[0080] (4) The polymer microsphere slurry obtained in step (2) is coated on the same side of the ceramic / resin diaphragm coating obtained in step (3) by spray coating, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com