Reticular porous composite isolation film and preparation method thereof

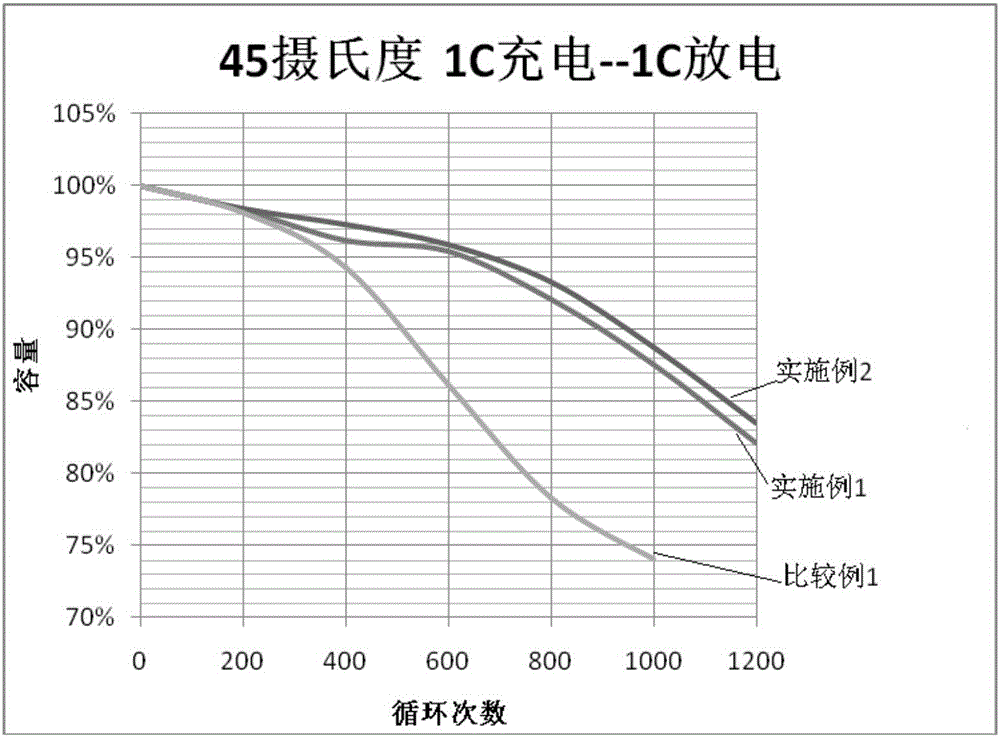

A reticular porous, isolating membrane technology, applied in the direction of separator/film/diaphragm/spacer element, electrical element, electrochemical generator, etc., can solve the problem of low closed cell temperature and membrane breaking temperature, poor ion exchange capacity, The problem of poor extrusion resistance and safety, to achieve the effect of increased film breaking temperature, strong wetting ability, and improved safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

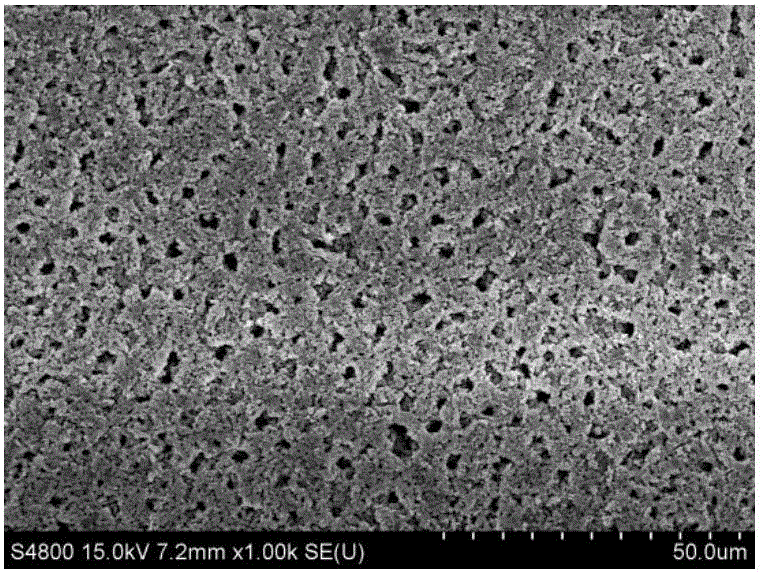

[0030] A method for preparing a mesh porous composite isolation membrane, comprising the steps of:

[0031] 1) Mix and grind insulating material particles magnesium oxide and deionized water until the insulating material particles D50=1.2 μm, and then stir for 5 hours at a temperature of 50° C. and a rotational speed of 130 r / min; wherein, the insulating material particles are mixed with The mass ratio of deionized water is 1;

[0032] 2) Add SH-PS-0801 acrylic emulsion pressure-sensitive adhesive (Jiangyin Shuanghua Technology Co., Ltd.) to the material obtained in step a) and stir for 3 hours at a temperature of 30°C and a speed of 330r / min. , the mass ratio of insulating material particles to binder is 0.1;

[0033] 3) Add calcium zinc stabilizer CZ-108 (Cindy Plastics) and polyethylene oxide PEO (Germany BASF) to the material obtained in step 2) in sequence, and stir for 2 Hours, mixed to make a slurry, wherein the mass ratio of insulating material particles to calcium-z...

Embodiment 2

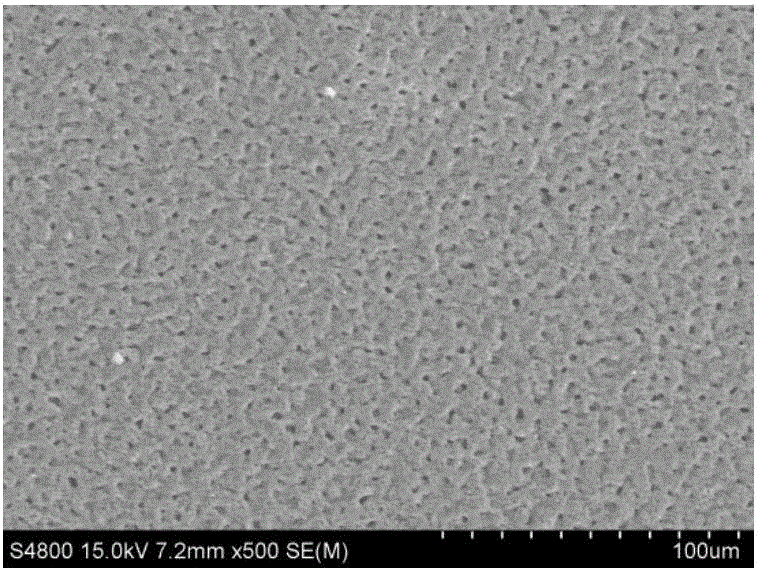

[0037] A method for preparing a mesh porous composite isolation membrane, comprising the steps of:

[0038] 1) Mix the titanium dioxide of the insulating material particles with deionized water and grind until the particle size of the insulating material particles reaches D50=1 μm, and then stir for 3 hours at a temperature of 70° C. and a rotational speed of 140 r / min; wherein, the insulating material particles are mixed with The mass ratio of deionized water is 0.6;

[0039] 2) Add SH-603 pressure-sensitive adhesive (Jiangyin Shuanghua Technology Co., Ltd.) to the material obtained in step a) and stir for 2 hours at a temperature of 35°C and a speed of 310r / min. The mass ratio of material particles to binder is 0.06;

[0040] 3) Add calcium zinc stabilizer CZ-108 (Cindy Plastics) and polyethylene oxide PEO (Germany BASF) to the material obtained in step 2) in sequence, and stir for 1.5 hours at a temperature of 30°C and a speed of 330r / min hours, mixed to make a slurry, wh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com