Coating diaphragm for lithium ion battery and preparation method thereof

A lithium-ion battery and coating technology, applied in the field of lithium-ion batteries, can solve the problems of hindering ion conduction and low safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] Correspondingly, the present invention also provides a preparation method of a lithium-ion battery coated separator, comprising the following steps: 5-15 parts by weight of PVDF powder, 2-10 parts by weight of additives, 40-90 parts by weight of the first solvent and 3 ~15 parts by weight of the second solvent are mixed, and mixed slurry is obtained after stirring, and the additive is selected from barium titanate, montmorillonite, carbon nanotubes, polyimide, styrene-butadiene latex, styrene-acrylic latex, polystyrene, One or more of polyacrylonitrile and aramid fiber; the mixed slurry is coated on one or both sides of a polyethylene-based film, pre-solidified, washed with water, and dried to obtain a lithium-ion battery coated separator.

[0023] The additive used in the present invention has the characteristics of high temperature resistance and not being swelled by the electrolyte. Therefore, the addition of the additive can effectively strengthen the skeleton struct...

Embodiment 1

[0031] A kind of lithium-ion battery coating separator and preparation method thereof, the additive that 10 weight parts PVDF powders, 4 weight parts carbon nanotubes and polyimide are formed, wherein the ratio of carbon nanotubes and polyimide is 6: The first solvent that 4,80 parts by weight dimethylacetamide and dimethylformamide are formed, wherein the ratio of dimethylacetamide and dimethylformamide is 5:5, 6 parts by weight of ethanol as the second solvent, The mixed slurry is made under the force of high-speed stirring, coated on both sides of the polyethylene diaphragm, and pre-coagulated in an environment with a relative humidity of 92%. The pre-coagulation time is 5s, the washing time is 10s, and it is dried at 45°C. , the thickness of the single-side coating of the obtained separator was 6 μm.

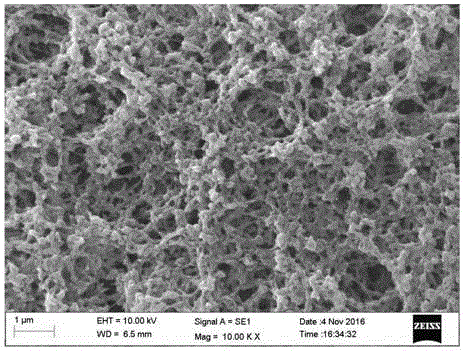

[0032] Scanning electron microscope analysis is carried out to the separator prepared in this embodiment, the result is as follows figure 1 shown.

Embodiment 2

[0034] A lithium-ion battery coated diaphragm and a preparation method thereof, an additive composed of 8 parts by weight of PVDF powder, 2.5 parts by weight of styrene-butadiene rubber and barium titanate, wherein the ratio of styrene-butadiene rubber and barium titanate is 4:6, 86 parts by weight of N-methylpyrrolidone and the first solvent of trimethyl phosphate, wherein the ratio of N-methylpyrrolidone and trimethyl phosphate is 7:3, the second solvent of 3.5 parts by weight of water and ethyl acetate, wherein The ratio of water and ethyl acetate is 8:2, and the mixed slurry is made under high-speed stirring force, coated on both sides of the polyethylene diaphragm, and pre-coagulated in an environment with a relative humidity of 95%. The pre-coagulation time 4s, washing time 25s, drying at 55°C, and the coating thickness on one side of the obtained separator is 4μm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com