Irradiation cross-linking lithium-ion battery diaphragm and preparation method thereof

A technology of irradiation and diaphragm, applied in the direction of battery components, circuits, electrical components, etc., can solve the problems of low closed cell temperature, insufficient current, high hole temperature, etc., achieve high temperature thermal shrinkage reduction, improve power battery The effect of power and high electrolyte absorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The preparation method of the irradiation crosslinked polyethylene porous diaphragm of the present invention comprises the following steps:

[0029] The first step: Soak the polyethylene porous diaphragm in a volatile organic solvent containing a photoinitiator with a mass concentration of 0.01-10% and a crosslinking agent with a mass concentration of 0.01-10% for more than 5 seconds, take it out and dry it at room temperature .

[0030] Step 2: Place the diaphragm soaked in Step 1 at a place 1-50mm below the surface of the aqueous solution of a hydrophilic monomer with a mass concentration of 0-5% and irradiate it with a radiation source for more than 2 seconds, or directly place the diaphragm after soaking The diaphragm is placed in an inert gas protective atmosphere and irradiated with a radiation source for more than 2 seconds. The radiation temperature is from room temperature to 110 ° C. The distance between the surface of the diaphragm and the radiation source is...

Embodiment 1

[0048] Soak the diaphragm 1 in a dichloromethane solution containing 1% mass concentration of photoinitiator BP and 1% mass concentration of crosslinking agent TAC for 1 min, take it out and dry it at room temperature. Soak the diaphragm in a constant temperature water bath filled with pure water and irradiate on both sides for 3 minutes in the irradiation device. The position of the film is 2mm away from the water surface, the water temperature is 30°C, the irradiation source is a 2KW high-pressure mercury lamp, and the distance between the mercury lamp and the film is 10cm. , irradiated to obtain a cross-linked polyethylene porous membrane.

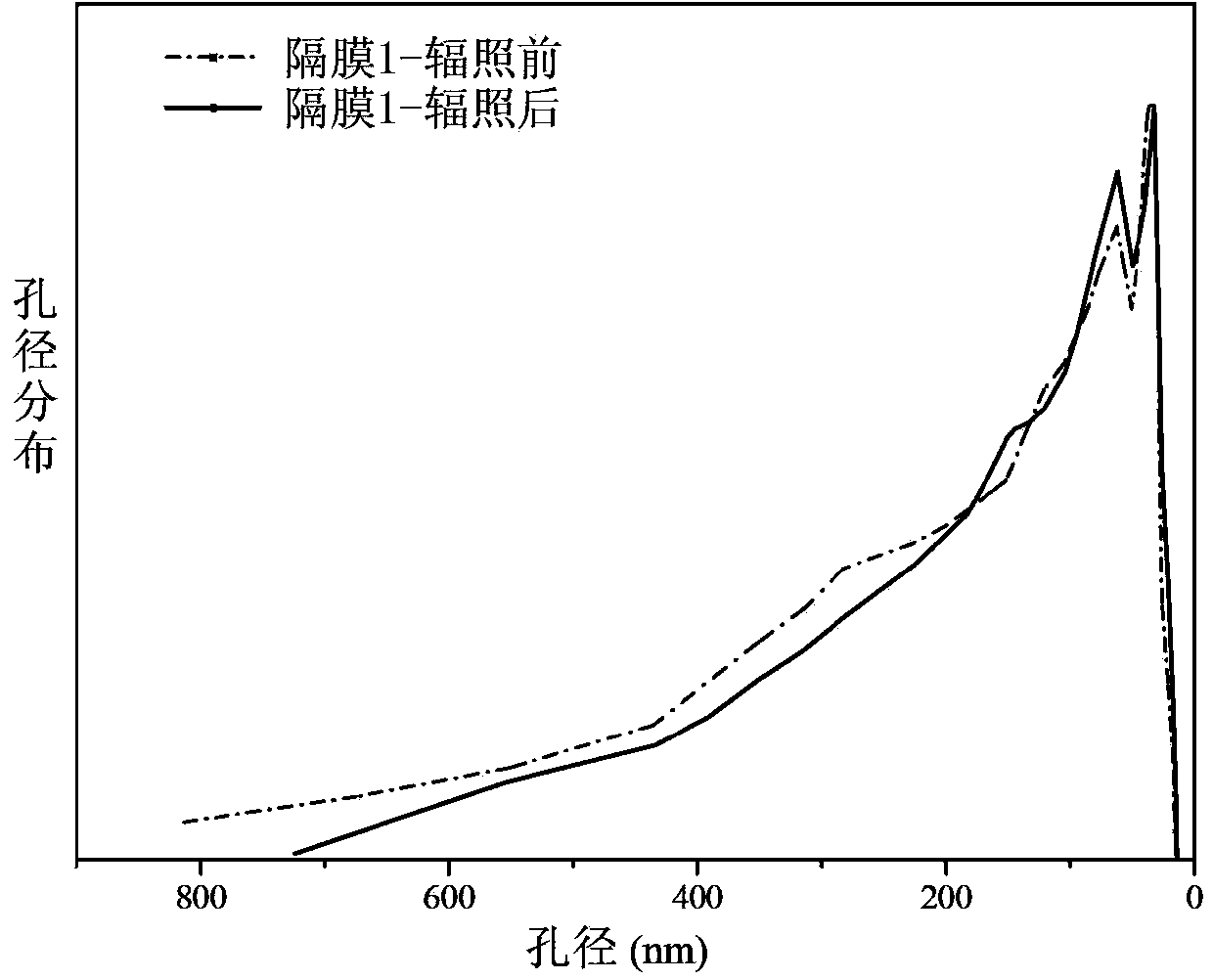

[0049] figure 1 Shown are the electron microscope pictures of the surface morphology of the diaphragm 1 before and after irradiation on both sides for 3 minutes, (a) before irradiation; (b) after irradiation. It can be seen from the figure that there is no change in the pore size of the diaphragm before and after irradiation. figure ...

Embodiment 2

[0060] Soak the diaphragm 1 in a dichloromethane solution containing 1% mass concentration of photoinitiator BP and 1% mass concentration of crosslinking agent TAC for 1 min, take it out and dry it at room temperature. Soak the diaphragm in a constant temperature water bath filled with pure water and irradiate on both sides for 1min in the irradiation device. The position of the film is 2mm away from the water surface, the water temperature is 30°C, the irradiation source is a 2KW high-pressure mercury lamp, and the distance between the mercury lamp and the film is 10cm. , irradiated to obtain a cross-linked polyethylene porous membrane.

[0061] It can be seen from Table 2 that there is no change in the porosity of the separator after irradiation. Figure 5 Shown are the changes in water contact angle on the membrane surface before and after the double-sided irradiation of membrane 1 for 1 min, (a) before irradiation, (b) after irradiation. It can be seen from the figure tha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| membrane rupture temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com