Battery isolating membrane preparation method

A separator and battery technology, applied in the field of electrochemistry, can solve the problems of high raw material and process costs, high requirements for ceramic slurry, and the inability to reduce the closed cell temperature of the separator at the same time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

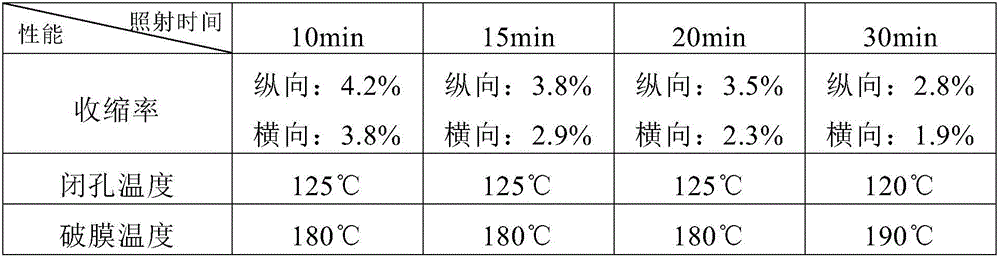

[0030] The preparation method of the battery separator film in this field has some conventional steps, for example, but not limited to, including raw material mixing, the mixture is extruded by a twin-screw extruder and then extruded through a slit die to a casting cooling roll to form a ribbon, The ribbon is extracted and cleaned to obtain a thin film. However, the method of the present invention is different from the prior art in that it also includes a cross-linking step, and the raw material contains a cross-linking aid. The crosslinking can be radiation crosslinking or chemical crosslinking, and radiation crosslinking is preferred. The auxiliary crosslinking agent can be mercaptobenzothiazole, benzothiazole disulfide, N-cyclohexylbenzothiazole sulfenamide, oxydivinylbenzothiazole sulfenamide, tetramethylthiuram monosulfide, Tetramethylthiuram disulfide, zinc dimethyldithiocarbamate, zinc diethyldithiocarbamate, diphenylguanidine, di-o-tolueneguanidine, ethylene thiourea, N...

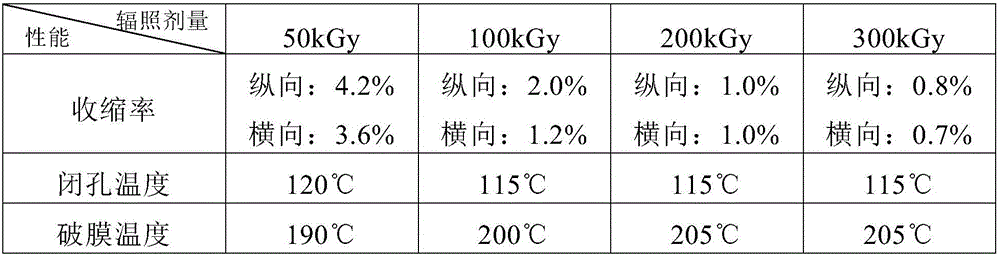

Embodiment 1

[0062] The density of 220 grams is 0.956g / cm 3 High-density polyethylene with a molecular weight of 5.0×10 for 100 grams 6 The ultra-high molecular weight polyethylene, 6.4 grams of antioxidant, 3.2 grams of cross-linking agent, and 2200 grams of mineral oil are added to the continuous batching and feeding kettle, and stirred at a speed of 50 rpm to mix the raw materials evenly.

[0063] The mixture is continuously fed into the twin-screw extruder, and the ultra-high molecular weight polyethylene, high-density polyethylene, antioxidant and auxiliary crosslinking agent are continuously dissolved in mineral oil in the twin-screw extruder at 180°C , And then continuously extruded by a twin-screw extruder at a speed of 200 rpm, the mixture continuously enters the slit die, the mixture is extruded through the slit die to the casting cooling roll, and it is cast at 80°C. Ribbon.

[0064] Put the obtained ribbon into an extraction tank containing dichloromethane for extraction to remove t...

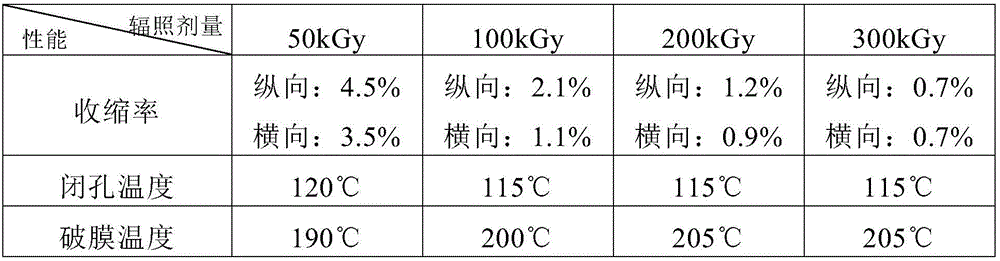

Embodiment 2

[0067] The density of 220 grams is 0.956g / cm 3 High-density polyethylene with a molecular weight of 5.0×10 for 100 grams 6 The ultra-high molecular weight polyethylene, 6.4 grams of antioxidant, 3.2 grams of cross-linking agent, and 2200 grams of mineral oil are added to the continuous batching and feeding kettle, and stirred at a speed of 50 rpm to mix the raw materials evenly.

[0068] The mixture is continuously fed into the twin-screw extruder, and the ultra-high molecular weight polyethylene, high-density polyethylene, antioxidant and auxiliary crosslinking agent are continuously dissolved in mineral oil in the twin-screw extruder at 180°C , And then continuously extruded by a twin-screw extruder at a speed of 200 rpm, the mixture continuously enters the slit die, the mixture is extruded through the slit die to the casting cooling roll, and it is cast at 80°C. Ribbon.

[0069] Put the obtained ribbon into an extraction tank containing dichloromethane for extraction to remove t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| energy | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com